Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Iron Worker Foreman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

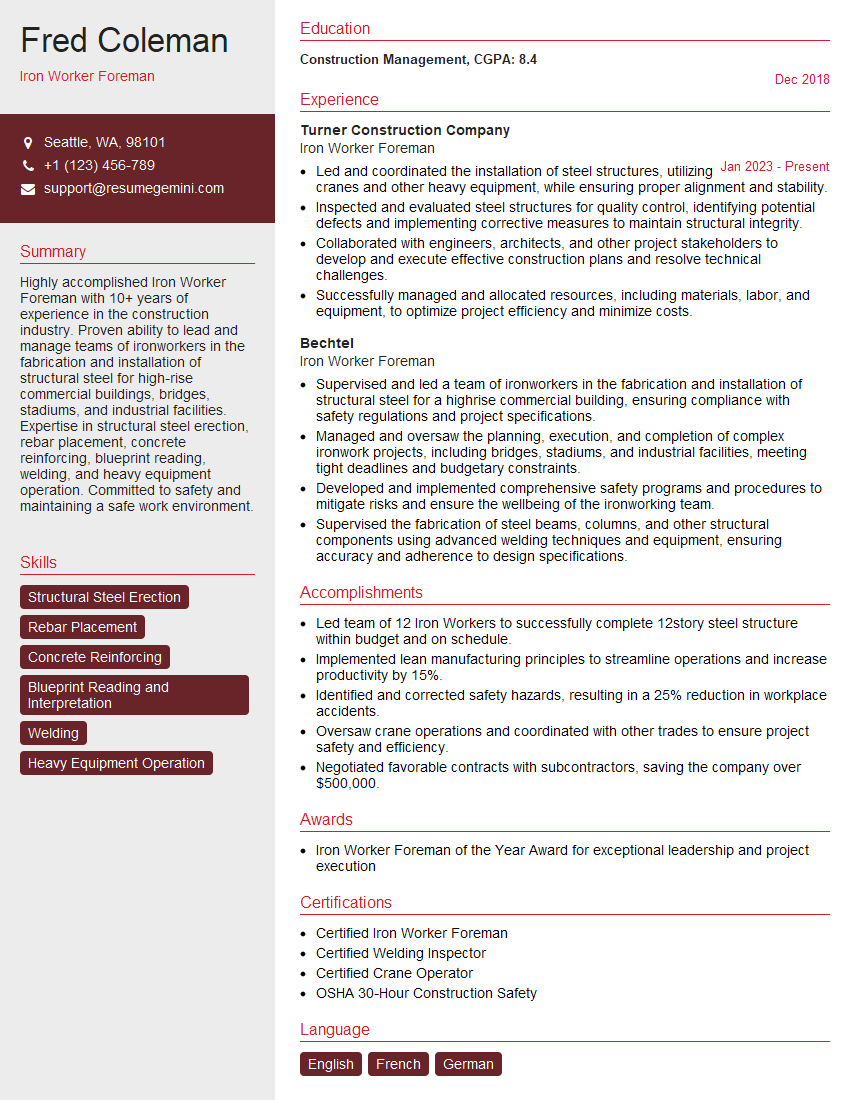

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Worker Foreman

1. What are the key responsibilities of an Iron Worker Foreman?

As an Iron Worker Foreman, my primary responsibilities include:

- Supervising and directing a team of ironworkers in the fabrication, erection, and installation of structural steel and ironwork

- Ensuring adherence to project specifications, safety regulations, and industry best practices

- Coordinating with other trades and project stakeholders to ensure timely and efficient project completion

- Managing materials and equipment, including inventory control and ordering

- Conducting regular safety inspections and enforcing safety protocols

- Training and mentoring ironworkers to enhance their skills and knowledge

2. Describe your experience in leading and motivating a team of ironworkers.

Leading and Motivating Team

- Demonstrated strong leadership skills by effectively directing and motivating a team of 15 ironworkers on a high-rise construction project

- Utilized clear communication, positive reinforcement, and constructive feedback to create a cohesive and productive team environment

Safety and Quality Control

- Maintained a safe work environment by implementing and enforcing comprehensive safety protocols

- Ensured the highest quality standards by conducting regular inspections and providing ongoing guidance to team members

3. How do you handle challenges or unexpected situations that arise during a project?

My approach to handling challenges involves:

- Staying calm and assessing the situation to identify the root cause of the problem

- Developing and implementing innovative solutions to overcome challenges while adhering to safety regulations

- Communicating effectively with my team and other stakeholders to ensure timely and effective resolution

- Documenting lessons learned to prevent similar issues from occurring in the future

4. What are the different types of welding processes used in ironwork and their applications?

In ironwork, we commonly use the following welding processes:

- Shielded Metal Arc Welding (SMAW): Suitable for welding thick materials and provides strong welds, often used for structural connections.

- Gas Metal Arc Welding (GMAW): Ideal for welding thin materials and offers high productivity, commonly used for sheet metal fabrication.

- Gas Tungsten Arc Welding (GTAW): Provides precise and high-quality welds, often used for critical applications such as piping systems.

- Flux-Cored Arc Welding (FCAW): Offers deep penetration and high deposition rates, suitable for welding heavy-duty structures.

5. Explain how you ensure the safety of your team while working with heavy machinery and materials.

Safety is paramount in my approach to project execution. I prioritize the following measures:

- Conducting thorough safety briefings and training sessions before any work commences

- Establishing clear safety protocols and enforcing their strict adherence

- Providing personal protective equipment (PPE) and ensuring its proper use

- Regularly inspecting equipment and materials to identify potential hazards

- Implementing a comprehensive safety management plan that includes emergency response procedures

6. Describe your experience with rigging and hoisting operations in ironwork.

I possess extensive experience in rigging and hoisting operations, including:

- Planning and supervising the safe and efficient movement of materials and equipment

- Selecting and using appropriate rigging equipment and techniques

- Inspecting and maintaining rigging gear to ensure its integrity

- Coordinating with crane operators and other personnel to execute complex lifts

7. How do you manage and allocate resources effectively to ensure project completion within timelines and budgets?

Effective resource management is critical to project success. My approach includes:

- Developing detailed project plans and schedules

- Allocating resources (manpower, materials, equipment) based on project requirements

- Monitoring progress and making adjustments as needed to stay on track

- Coordinating with suppliers and subcontractors to ensure timely delivery

- Utilizing project management software to optimize resource utilization

8. What are your strategies for maintaining a positive and collaborative work environment on the job site?

Positive and collaborative work environments are essential for productivity and safety. I foster this through:

- Encouraging open communication and feedback

- Promoting teamwork and mutual respect among team members

- Recognizing and rewarding individual and team achievements

- Addressing conflicts promptly and constructively

- Providing opportunities for professional development and growth

9. How do you stay up-to-date with the latest industry trends and best practices in ironwork?

Staying abreast of industry advancements is crucial. I engage in continuous learning through:

- Attending industry conferences and workshops

- Reading technical publications and research papers

- Participating in online forums and discussion groups

- Seeking mentorship from experienced professionals

- Exploring innovative technologies and their applications in ironwork

10. What are your career goals and aspirations in the ironworking industry?

My career goals include:

- Further developing my leadership and managerial skills

- Expanding my knowledge and expertise in all aspects of ironwork

- Contributing to the advancement of the industry through innovative solutions

- Mentoring and training future generations of ironworkers

- Ultimately, I aspire to lead a large-scale ironworking team on complex and challenging projects

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Worker Foreman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Worker Foreman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron Worker Foremen oversee the installation and repair of structural steel and iron components in various construction projects. They are responsible for managing a team of ironworkers, ensuring project deadlines are met, and adhering to safety regulations.

1. Project Management

Foremen plan, organize, and coordinate ironwork activities, including material procurement, scheduling, and manpower allocation.

- Develop and implement work schedules and timelines.

- Monitor project progress and make necessary adjustments.

- Coordinate with other trades and subcontractors to ensure smooth workflow.

2. Team Supervision

Foremen lead and supervise a team of ironworkers, providing guidance, training, and performance evaluations.

- Assign tasks and monitor worker progress.

- Provide on-the-job training and mentorship.

- Enforce safety regulations and ensure a safe work environment.

3. Safety and Quality Control

Foremen are responsible for ensuring a safe and productive worksite, as well as maintaining the quality of ironwork.

- Conduct regular safety inspections and implement corrective measures.

- Enforce proper use of tools and equipment.

- Inspect ironwork for compliance with blueprints and specifications.

4. Communication and Reporting

Foremen communicate with project managers, engineers, and other stakeholders to provide updates, resolve issues, and ensure project success.

- Submit progress reports and documentation.

- Attend meetings and participate in decision-making.

- Respond to inquiries and provide technical advice.

Interview Tips

Preparing thoroughly for an Iron Worker Foreman interview can significantly improve your chances of success. Here are some tips:

Research the Company and Industry

Familiarize yourself with the company’s values, projects, and industry trends. This demonstrates your interest and knowledge of the field.

Practice Answering Common Interview Questions

Prepare for questions about your experience, technical skills, and leadership qualities. Craft thoughtful and concise responses that highlight your qualifications.

Use the STAR Method

When answering behavioral interview questions, use the STAR method (Situation, Task, Action, Result) to provide specific examples of your relevant skills.

Emphasize Safety and Quality

Highlight your commitment to safety and the importance you place on ensuring high-quality ironwork. This is a crucial aspect of the role.

Demonstrate Your Communication Skills

Articulate your ability to communicate effectively with team members, supervisors, and clients. Showcase your listening, presentation, and conflict-resolution abilities.

Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the position and company. Prepare a few questions about the project, team, and company culture.

Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately and arrive on time for your interview. This demonstrates respect for the interviewer and company.

Next Step:

Now that you’re armed with the knowledge of Iron Worker Foreman interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Iron Worker Foreman positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini