Are you gearing up for a career in Iron Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Iron Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

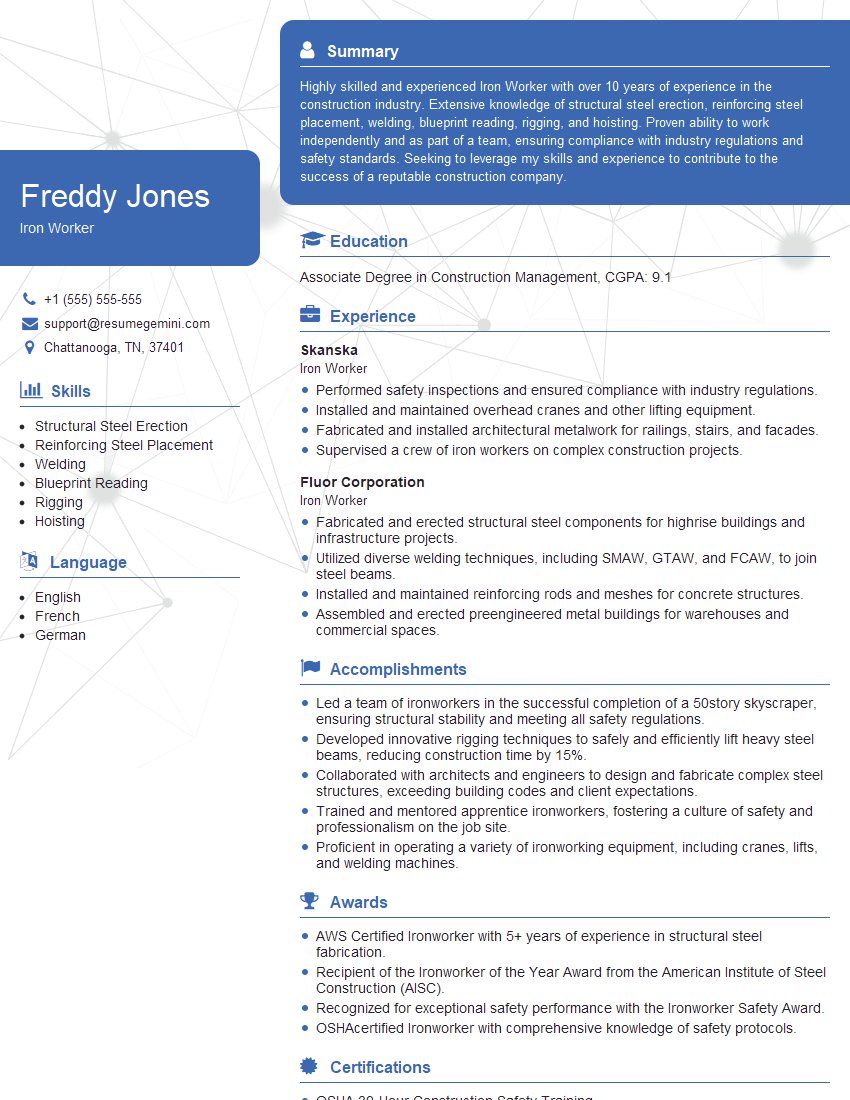

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Worker

1. What are the different types of welding processes used in ironworking?

There are various welding processes commonly used in ironworking, including:

- Shielded Metal Arc Welding (SMAW), also known as stick welding, uses an electrode coated with flux to create an arc and deposit molten metal.

- Gas Metal Arc Welding (GMAW), also called MIG welding, uses a continuously fed wire electrode and an inert gas to protect the weld pool.

- Gas Tungsten Arc Welding (GTAW), or TIG welding, uses a non-consumable tungsten electrode and an inert gas to create an arc and weld.

2. Describe the steps involved in fabricating a steel beam.

- Interpret blueprints and mark dimensions on steel plates.

- Use measuring tools like rulers, squares, and levels for precision.

- Operate tools like plasma cutters, oxy-fuel torches, or shears to cut steel according to the marked dimensions.

- Ensure clean and accurate cuts for proper fit.

Layout

Cutting

- Use bending machines or presses to shape the steel plates into desired angles or profiles.

- Calculate the correct amount of force and bending radii to achieve the desired shape.

- Assemble the cut and formed steel pieces together using welding techniques.

- Select the appropriate welding process based on material thickness and joint design.

Forming

Welding

- Inspect welds for quality and adherence to specifications.

- Use visual inspection, non-destructive testing methods, and measuring tools to ensure structural integrity.

Inspection

3. How do you ensure the structural integrity of ironwork fabrications?

To ensure structural integrity, I follow these key practices:

- Adhere to industry standards and building codes.

- Use high-quality materials and components.

- Employ proper welding techniques and follow welding procedures.

- Conduct thorough inspections and testing at various stages of fabrication.

- Consult with engineers and architects to review designs and specifications.

4. How do you handle working at heights on ironwork projects?

Working at heights requires safety precautions. I prioritize the following:

- Wear appropriate personal protective equipment, including safety harnesses and helmets.

- Follow established safety protocols and use proper scaffolding or aerial lifts.

- Inspect equipment regularly and ensure it meets safety standards.

- Stay aware of my surroundings and maintain proper balance.

5. What are the common safety hazards associated with ironworking?

- Falls from heights

- Welding-related hazards, such as burns, fumes, and electric shock

- Heavy lifting

- Exposure to noise and vibration

- Working in confined spaces

6. How do you maintain and calibrate ironworking tools and equipment?

Regular maintenance and calibration are crucial for accuracy and safety. I:

- Follow manufacturer’s maintenance schedules.

- Inspect tools and equipment for damage or wear.

- Clean and lubricate components as needed.

- Calibrate measuring tools and welding equipment periodically.

- Keep a maintenance log to track inspections and repairs.

7. Can you describe your experience in blueprint reading for ironwork projects?

I am proficient in reading and interpreting blueprints for ironwork fabrication. My experience includes:

- Understanding symbols, dimensions, and specifications.

- Identifying material types, sizes, and quantities.

- Visualizing the final product and assembly sequence.

- Collaborating with engineers and architects to clarify design details.

8. What are the different types of connections used in ironwork?

Various types of connections are used in ironwork, including:

- Bolted connections

- Riveted connections

- Welded connections

- Pinned connections

The selection of connection type depends on factors such as load requirements, joint configuration, and material properties.

9. How do you ensure proper fit-up and alignment of ironwork components?

- Use precision measuring tools and layout techniques.

- Employ jigs and fixtures for accurate alignment.

- Check measurements and adjust components as necessary.

- Tack weld components temporarily to hold them in place.

10. What are the quality control procedures followed in ironwork fabrication?

Quality control measures ensure the accuracy and integrity of ironwork fabrications. Common procedures include:

- Visual inspections

- Dimensional checks

- Non-destructive testing methods

- Welding inspections

- Material testing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Iron workers play a crucial role in the construction industry by installing and assembling various iron and steel structures, including bridges, buildings, and other infrastructure projects.

1. Structural Assembly

Fabricate, assemble, and erect structural steel components, such as beams, girders, columns, and trusses.

2. Welding

Use various welding techniques to join and reinforce metal structures, ensuring strength and durability.

3. Rigging and Lifting

Operate cranes, hoists, and other equipment to safely lift, position, and secure heavy steel components.

4. Blueprint Reading and Interpretation

Study blueprints and technical drawings to understand project specifications and follow instructions for assembly.

5. Safety Compliance

Adhere to strict safety protocols, including wearing appropriate safety gear, maintaining equipment, and following safety procedures.

Interview Tips

Preparing thoroughly for an Iron Worker interview can significantly improve your chances of success.

1. Research the Company and Position

Gather information about the company’s history, culture, and current projects. Understand the specific responsibilities and requirements of the Iron Worker position you’re applying for.

- Visit the company’s website and LinkedIn profile.

- Read industry news and articles to stay up-to-date on best practices and industry trends.

2. Practice Your Responses

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice answering these questions out loud to improve your delivery.

- Tell me about your experience with structural assembly and welding.

- Describe a project where you faced a safety challenge and how you overcame it.

3. Emphasize Safety

Iron work involves high levels of risk, so hiring managers prioritize safety. Highlight your safety procedures, training, and commitment to maintaining a safe work environment.

4. Showcase Physical and Mental Attributes

Iron work requires physical strength and endurance. Discuss your physical capabilities and ability to work in demanding conditions. Also, mention your attention to detail and problem-solving skills.

- Provide examples of tasks where you demonstrated physical strength and stamina.

- Describe situations where you applied logical thinking and found effective solutions.

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows engagement and interest. Prepare questions about the company’s future projects, training opportunities, or safety initiatives.

- What are the company’s plans for expansion or new projects in the upcoming year?

- What opportunities are available for professional development and advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Iron Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!