Are you gearing up for a career in Ironmolder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ironmolder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

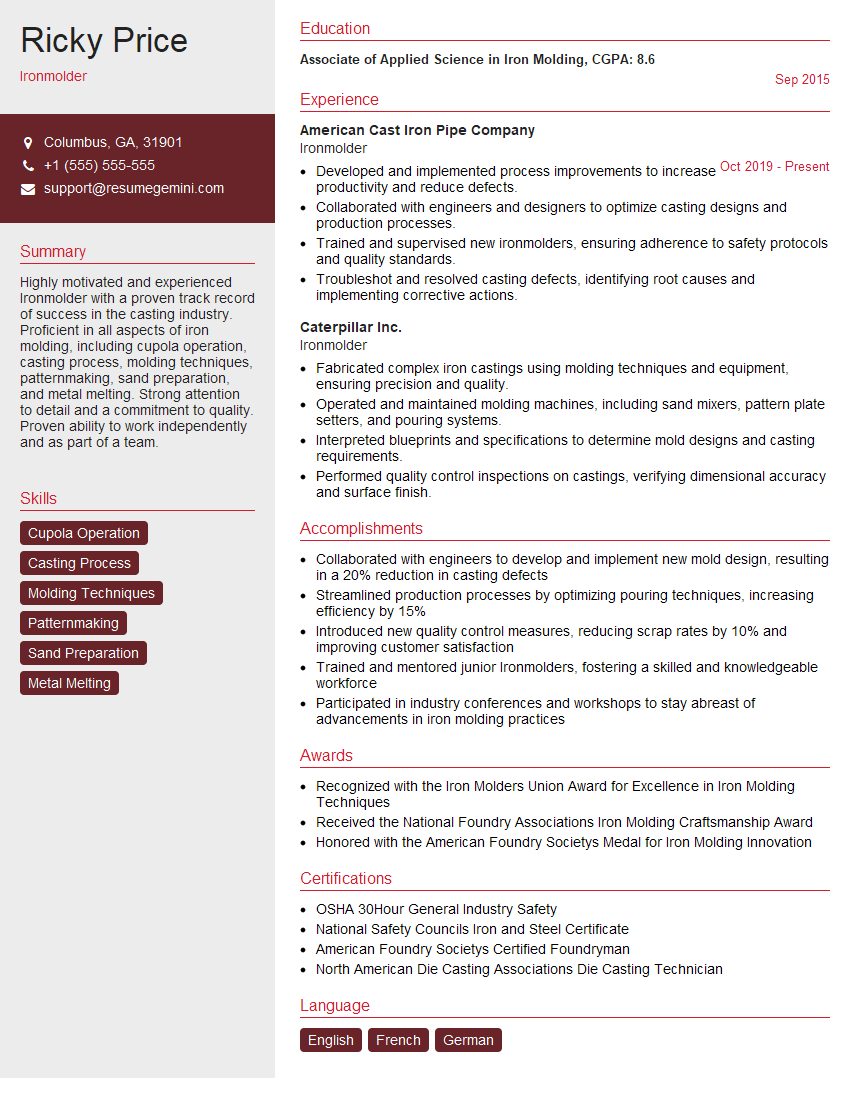

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ironmolder

1. What is the importance of sand preparation in the iron molding process?

Sand preparation is a crucial step as it determines the quality of the mold. Well-prepared sand has the following benefits:

- Provides adequate strength and permeability to the mold.

- Ensures proper flow of molten metal into the mold cavity.

- Prevents defects such as scabs, blowholes, and inclusions in the final casting.

2. Describe the different types of pattern equipment used in iron molding.

Pattern equipment can be classified based on its material and reusability:

Reusable Patterns:

- Metallic Patterns: Made of metals like aluminum, brass, or iron, these patterns are highly durable and can be used for multiple castings.

- Non-Metallic Patterns: Made of materials like wood, plastic, or epoxy, these patterns are less durable but suitable for smaller batches.

Non-Reusable Patterns:

- Cope and Drag Patterns: Used for making one-time molds and are destroyed in the process.

- Sacrificial Patterns: Made from materials like polystyrene or wax, these patterns are embedded in the sand and vaporized by the molten metal.

3. Explain the steps involved in preparing a sand mold for iron casting.

Sand mold preparation involves several key steps:

- Pattern Preparation: The pattern is checked for accuracy and any necessary repairs are made.

- Flask Preparation: The molding flask (Cope and Drag) is prepared to contain the sand.

- Sand Preparation: Suitable sand is mixed with binders and additives to achieve the desired properties.

- Molding: Sand is packed around the pattern in the flask, creating the mold cavities.

- Pattern Removal: The pattern is carefully removed, leaving behind the mold impressions.

- Mold Finishing: The mold is inspected, repaired if needed, and prepared for pouring.

4. Discuss the factors that affect the quality of iron castings.

Iron casting quality depends on several factors:

- Mold Quality: Well-prepared molds with proper compaction, permeability, and strength ensure accurate castings.

- Metal Quality: The composition and cleanliness of the molten iron significantly impact casting quality.

- Casting Process: Proper pouring temperature, solidification rate, and cooling practices influence the microstructure and properties of the casting.

- Pattern Design: Patterns should be designed considering casting tolerances, draft angles, and potential defects.

- Equipment Maintenance: Well-maintained equipment, such as furnaces, mixers, and molding machines, contribute to consistent casting quality.

5. How do you troubleshoot common casting defects such as blowholes, scabs, and shrinkage cavities?

Troubleshooting casting defects involves identifying the root cause and implementing corrective measures:

- Blowholes: Caused by trapped air or gases in the mold. Solutions include improving sand permeability, ensuring proper venting, and degassing the molten metal.

- Scabs: Result from inclusions or foreign materials in the sand or metal. To prevent them, use clean sand, avoid mold contamination, and remove slag from the molten metal.

- Shrinkage Cavities: Occur due to the solidification and cooling of the molten metal. Addressing these defects involves optimizing pouring temperature, using chills or risers, and controlling cooling rates.

6. Describe the different types of iron used in casting and their properties.

Common types of iron used in casting include:

- Gray Cast Iron: Graphite flakes in the microstructure provide good machinability and dampening properties.

- White Cast Iron: Cementite is present in the microstructure, resulting in high hardness and wear resistance but poor machinability.

- Malleable Cast Iron: Heat treatment transforms the cementite into nodules, improving strength and ductility.

- Ductile Cast Iron: Spheroidal graphite in the microstructure provides high strength, ductility, and toughness.

7. Explain the importance of gating and risering systems in iron casting.

Gating and risering systems are crucial for controlling the flow and solidification of molten metal in the mold:

- Gating System: Channels the molten metal smoothly into the mold cavity, reducing turbulence and minimizing defects.

- Riser System: Compensates for the shrinkage of molten metal during solidification, ensuring a sound casting.

8. Discuss the safety precautions to be taken during iron molding operations.

Safety is paramount in iron molding. Precautions include:

- Using appropriate personal protective equipment (PPE) such as gloves, safety glasses, and fire-resistant clothing.

- Maintaining a clean and organized work area to prevent tripping hazards.

- Handling molten metal with extreme care, using proper tools and protective gear.

- Following proper ventilation practices to minimize exposure to fumes and dust.

- Being aware of potential hazards such as burns, cuts, and explosions.

9. Describe the environmental impact of iron molding and how it can be minimized.

Iron molding can pose environmental concerns, but efforts are made to minimize these impacts:

- Waste Management: Implementing recycling programs for scrap metal and sand, reducing waste.

- Emission Control: Using pollution control devices to filter emissions from furnaces and exhaust systems.

- Water Conservation: Employing water-saving measures in cleaning and cooling processes.

- Sustainable Materials: Exploring the use of environmentally friendly materials in pattern making and mold preparation.

10. How do you stay updated with the latest advancements in iron molding technology?

To keep abreast of industry advancements, I engage in the following activities:

- Attending conferences, workshops, and webinars.

- Reading technical publications, journals, and online resources.

- Participating in professional organizations and networks.

- Collaborating with research institutions and industry experts.

- Exploring new technologies and methodologies through hands-on projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ironmolder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ironmolder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ironmolders are responsible for producing iron castings in a variety of shapes and sizes. Their key responsibilities include:1. Pouring molten iron into molds

2. Operating and maintaining molding equipment

3. Inspecting castings for defects

4. Making repairs to castings

5. Working with other foundry personnel to ensure the smooth operation of the foundry

6. Maintaining a clean and safe work area

7. Keeping records of mold production and casting quality

Interview Tips

To ace an interview for an ironmolder position, it is important to be prepared and to have a strong understanding of the key job responsibilities. Here are some tips to help you prepare for your interview:1. Research the company and the position

Take some time to learn about the company you are interviewing with, as well as the specific position you are applying for. This will help you to better understand the company’s culture and the requirements of the job. You can find information about the company on their website, in their annual reports, and in articles about the company in the news.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely. You can find examples of common interview questions and answers on the internet or in books about job interviews.

3. Prepare questions to ask the interviewer

Asking the interviewer questions at the end of the interview shows that you are interested in the position and that you have done your research. Prepare a few questions in advance that you can ask the interviewer about the company, the position, or the industry. This is also an opportunity for you to learn more about the company and the position to see if it is a good fit for you.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview, as being late can be seen as disrespectful. It is also important to be polite and respectful to the interviewer, and to maintain eye contact when you are speaking.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ironmolder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.