Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ironworker-Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

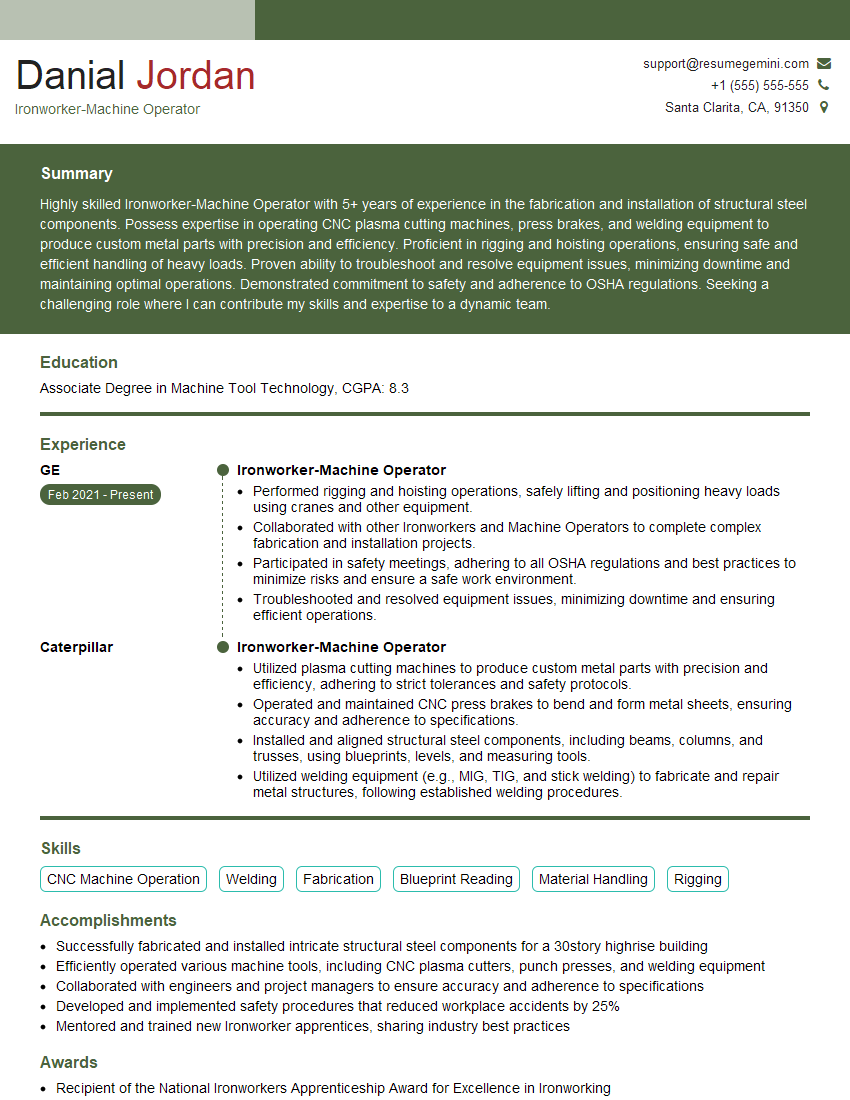

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ironworker-Machine Operator

1. What specific types of ironworking machinery have you operated in the past?

– CNC laser cutting machines – CNC press brakes – CNC turret punches – Hydraulic shears – Ironworkers

2. What is the proper procedure for setting up and operating a CNC laser cutting machine?

Pre-Setup

- Inspect the machine and ensure it is in good working order.

- Load the material to be cut onto the machine.

- Secure the material to the machine table.

Setup

- Select the appropriate cutting parameters for the material being cut.

- Generate the cutting program using the CNC software.

- Load the cutting program into the machine.

Operation

- Start the cutting process.

- Monitor the cutting process and make any necessary adjustments.

- Unload the finished product from the machine.

3. How do you troubleshoot a CNC press brake if it is not bending the material correctly?

- Check the material thickness and ensure it is within the machine’s capacity.

- Check the die and punch for wear or damage.

- Check the machine’s hydraulic pressure and ensure it is within the correct range.

- Check the CNC program and ensure it is correct.

- Tighten any loose bolts or screws on the machine.

4. What is the difference between a hydraulic shear and a mechanical shear?

- Hydraulic shears use hydraulic pressure to cut the material, while mechanical shears use a mechanical force.

- Hydraulic shears are typically more powerful than mechanical shears and can cut thicker materials.

- Hydraulic shears are also more versatile than mechanical shears and can cut a variety of shapes.

5. How do you maintain an ironworker machine to ensure it is operating safely and efficiently?

- Inspect the machine regularly for wear or damage.

- Lubricate the machine according to the manufacturer’s instructions.

- Clean the machine regularly to remove any dirt or debris.

- Follow the manufacturer’s recommended maintenance schedule.

6. What safety precautions should be taken when operating an ironworker machine?

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Keep your hands away from the cutting area.

- Never operate the machine when it is not in good working order.

- Follow all of the manufacturer’s safety instructions.

7. How do you calculate the correct feed rate for a CNC turret punch?

- Determine the material thickness.

- Determine the punch diameter.

- Refer to the manufacturer’s recommended feed rates for the material and punch diameter.

8. What is the purpose of a stripper in a CNC turret punch?

- To prevent the material from sticking to the punch.

- To help clear the slug from the punch.

- To improve the accuracy and quality of the punched holes.

9. What is the difference between a CNC plasma cutter and a CNC waterjet cutter?

- CNC plasma cutters use a plasma arc to cut the material, while CNC waterjet cutters use a high-pressure water jet.

- CNC plasma cutters are typically faster than CNC waterjet cutters, but CNC waterjet cutters can cut a wider variety of materials.

- CNC plasma cutters can cut thicker materials than CNC waterjet cutters.

10. What is the purpose of a CNC controller?

- To control the movement of the machine’s axes.

- To store and execute the cutting program.

- To monitor the machine’s sensors and alarms.

- To provide feedback to the operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ironworker-Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ironworker-Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ironworker-Machine Operators are highly skilled professionals who are responsible for operating and maintaining complex machinery to produce iron products. They are responsible for various tasks, including:

1. Machine Operation

Ironworker-Machine Operators are responsible for operating a variety of machines, including lathes, drills, saws, and grinders. They must be able to set up the machines correctly and operate them safely and efficiently.

- Setting up and operating various machine tools, such as lathes, drills, milling machines, and grinders

- Monitoring machine performance and making adjustments as needed

- Ensuring the accuracy and precision of finished products

2. Production Quality

Ironworker-Machine Operators are also responsible for ensuring the quality of the products they produce. They must be able to inspect finished products for defects and make adjustments to the machines as needed.

- Inspecting finished products for defects

- Testing products to ensure they meet specifications

- Making adjustments to machines and processes to improve quality

3. Machine Maintenance

In addition to operating and maintaining machines, Ironworker-Machine Operators are also responsible for performing basic maintenance on their equipment. They must be able to clean and lubricate machines, and troubleshoot and repair minor problems.

- Performing scheduled maintenance on machines

- Troubleshooting and repairing minor machine problems

- Keeping machines clean and lubricated

4. Safety

Ironworker-Machine Operators must also be aware of the safety hazards associated with their work. They must be able to follow safety procedures and wear appropriate safety gear.

- Following safety procedures and wearing appropriate safety gear

- Identifying and mitigating potential hazards

- Reporting any accidents or injuries

Interview Tips

Preparing for an interview for an Ironworker-Machine Operator position can be daunting, but with the right approach, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Take the time to research the company you are interviewing with and the specific position you are applying for. This will help you understand the company’s culture, business goals, and what they are looking for in a candidate.

- Visit the company’s website to learn about their products, services, and history.

- Review the job description carefully to understand the key responsibilities and qualifications.

- Read industry news and articles to stay up-to-date on the latest trends and advancements.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in Ironworker-Machine Operator interviews. By practicing your answers to these questions, you can feel more confident and prepared during the interview.

- Tell me about your experience operating and maintaining ironworking machinery.

- What are some of the challenges you have faced in your previous role as an Ironworker-Machine Operator?

- How do you ensure the quality of your finished products?

- What are your safety procedures when working with ironworking machinery?

- Why are you interested in working for our company?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. You can do this by providing specific examples of your work and accomplishments.

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated a lathe,” say “I operated a lathe to produce 100 widgets per hour, exceeding the production target by 15%.”

- Use action verbs to describe your skills and experience. For example, instead of saying “I am a good communicator,” say “I effectively communicated with team members to coordinate production schedules.”

- Be prepared to talk about your experience with specific types of ironworking machinery.

4. Be Professional and Enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be positive and enthusiastic about the opportunity to work for the company.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ironworker-Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.