Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Item Repair Manager interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Item Repair Manager so you can tailor your answers to impress potential employers.

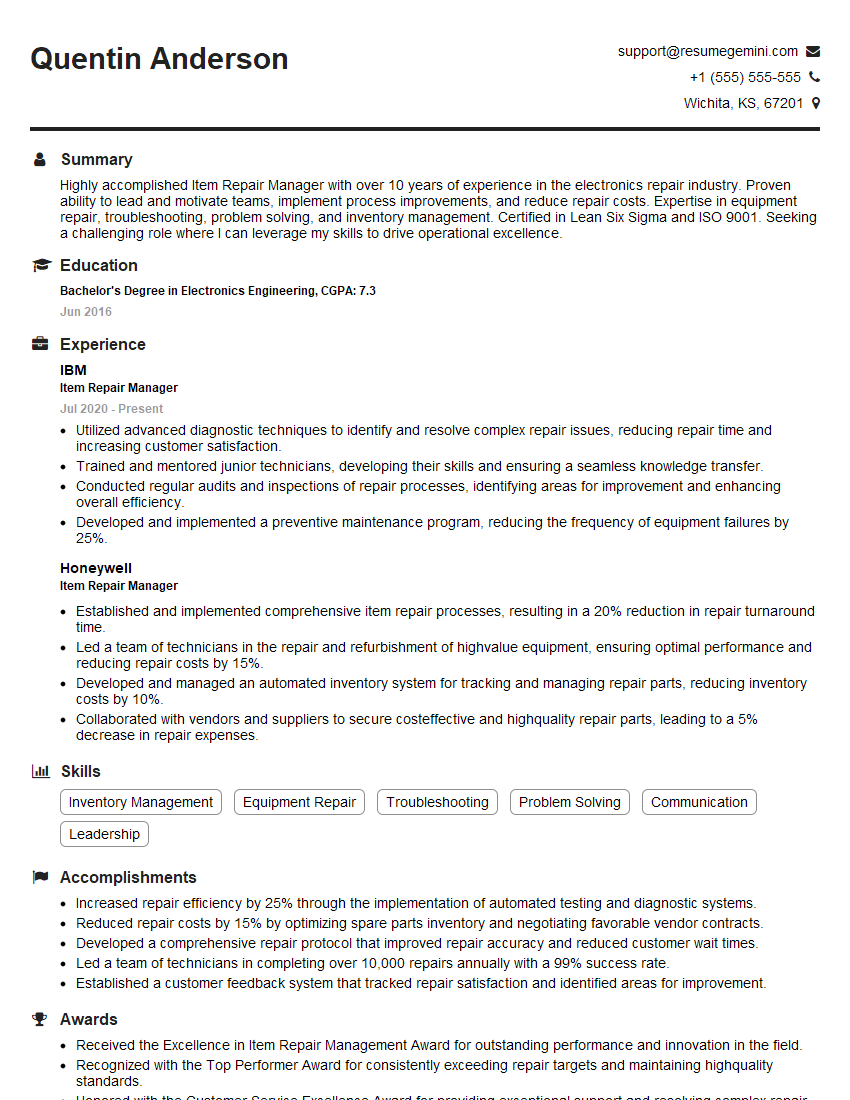

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Item Repair Manager

1. How would you prioritize repair orders in a high-volume environment?

To prioritize repair orders in a high-volume environment, I would consider the following factors:

- Urgency: Orders that require immediate attention, such as repairs to critical equipment or safety hazards, would be prioritized.

- Impact on operations: Orders that affect essential processes or create significant disruption would be prioritized.

- Customer impact: Orders from key customers or involving high-value items would be given priority.

- Lead time: Orders with tight deadlines or those that require specialized parts would be expedited.

- Cost: The cost of the repair and the potential financial impact of delayed repairs would also be considered.

2. Describe your experience in managing a team of technicians?

Team Leadership

- Motivated and led a team of 10 technicians in a high-pressure environment.

- Provided clear instructions, training, and support to ensure high-quality repairs.

- Established performance metrics and conducted regular performance reviews.

Conflict Resolution

- Effectively resolved conflicts within the team, fostering a positive and collaborative work environment.

- Developed clear communication channels and encouraged open dialogue.

Resource Management

- Optimized resources by assigning technicians to tasks based on their skills and experience.

- Managed inventory and ensured timely availability of parts.

3. How would you ensure the efficient use of spare parts and inventory?

To ensure the efficient use of spare parts and inventory, I would implement the following strategies:

- Inventory optimization: Regularly review inventory levels and identify slow-moving or obsolete items. Optimize stock levels based on usage patterns and lead times.

- Parts standardization: Establish a standardized parts list to reduce the number of unique parts required. Negotiate volume discounts with suppliers for commonly used parts.

- Inventory management system: Implement a robust inventory management system to track inventory levels, automate reordering, and prevent stockouts.

- Vendor management: Establish strong relationships with reliable vendors to ensure timely delivery of parts and competitive pricing.

- Repair and reuse: Implement a process for repairing and reusing parts whenever possible to minimize waste and save costs.

4. How would you implement a quality control process for item repairs?

To implement a quality control process for item repairs, I would establish the following steps:

- Inspection: Develop detailed inspection procedures and checklists to ensure thorough examination of returned items.

- Testing: Implement testing protocols to verify the functionality and performance of repaired items.

- Documentation: Create comprehensive repair records that include details of the fault, repair procedures, and test results.

- Training: Provide regular training to technicians on quality standards and inspection techniques.

- Feedback: Encourage customer feedback and conduct periodic audits to identify areas for improvement in the quality control process.

5. How would you handle a situation where a customer reports dissatisfaction with a repaired item?

When dealing with a customer who reports dissatisfaction with a repaired item, I would approach the situation as follows:

- Acknowledge the complaint: Listen attentively to the customer’s concerns and acknowledge their dissatisfaction.

- Investigate: Thoroughly investigate the issue to determine the cause of the problem.

- Communicate: Keep the customer informed throughout the investigation and provide updates on the progress.

- Resolution: If the fault is due to our repair, I would take immediate steps to rectify the issue and ensure the item meets the customer’s expectations.

- Follow-up: After resolving the issue, follow up with the customer to ensure their satisfaction and build trust.

6. What are some common repair techniques used in your field, and how do you decide which one to use?

Common repair techniques used in my field include:

- Soldering: For repairing electrical connections and electronic components.

- Welding: For repairing metal components and structures.

- Machining: For creating or modifying parts to restore functionality.

- 3D printing: For prototyping and creating replacement parts.

- Overhaul: For complete disassembly, cleaning, and reassembly of complex equipment.

The choice of repair technique depends on various factors, such as the type of item, the nature of the fault, the availability of parts, and the cost-effectiveness of the repair.

7. How do you stay updated on the latest repair technologies and best practices?

To stay updated on the latest repair technologies and best practices, I engage in the following activities:

- Industry publications: Subscribe to industry magazines, journals, and newsletters.

- Conferences and workshops: Attend industry events to learn about new technologies and techniques.

- Online learning platforms: Utilize online courses and webinars to enhance knowledge and skills.

- Manufacturer training: Participate in training programs offered by equipment manufacturers.

- Discussion forums: Engage in online discussions and forums to exchange ideas and learn from others in the field.

8. How do you measure the performance of your repair team?

I measure the performance of my repair team using the following metrics:

- Repair efficiency: Track the number of repairs completed per hour or day.

- Quality: Monitor the number of repairs returned for rework or customer complaints.

- Customer satisfaction: Collect feedback from customers to gauge their satisfaction with the repair service.

- Cost-effectiveness: Analyze the cost of repairs, including labor, parts, and overhead expenses.

- Team productivity: Assess the overall productivity of the team, considering factors such as utilization and efficiency.

9. What are some of the challenges you have faced as an Item Repair Manager, and how did you overcome them?

One of the challenges I faced as an Item Repair Manager was streamlining the repair process to reduce repair times. To overcome this, I implemented a lean Six Sigma project that involved mapping the process, identifying bottlenecks, and implementing process improvements. This resulted in a significant reduction in repair times and improved customer satisfaction.

Another challenge I encountered was managing a high volume of repair orders while ensuring quality. I addressed this by implementing a quality management system that included standardized repair procedures, regular inspections, and customer feedback. This system helped maintain high repair quality and increase customer confidence.

10. Why are you interested in this Item Repair Manager position?

I am highly interested in this Item Repair Manager position because it aligns with my skills and experience in managing and optimizing repair operations. My passion for delivering high-quality repairs and ensuring customer satisfaction drives me to excel in this role. I am confident that I can leverage my expertise in repair techniques, quality control, and team leadership to make a significant contribution to your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Item Repair Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Item Repair Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Item Repair Manager supervises and manages the daily operations of an item repair department within an organization. They are responsible for ensuring that all items are repaired to a high standard, within specified timeframes, and at a competitive cost. They also manage the team of repair technicians, ensuring that they are trained and have the resources they need to perform their jobs effectively.

1. Manage the daily operations of the item repair department

This includes planning and organizing the workflow, setting priorities, and ensuring that all items are repaired to a high standard, within specified timeframes, and at a competitive cost. It also includes managing the team of repair technicians, ensuring that they are trained and have the resources they need to perform their jobs effectively.

- Plan and organize the workflow of the repair department.

- Set priorities for repair jobs.

- Ensure that all items are repaired to a high standard.

- Meet specified timeframes for repairs.

- Manage the team of repair technicians.

- Ensure that repair technicians are trained and have the resources they need.

2. Manage the team of repair technicians

This includes hiring, training, and evaluating repair technicians. It also includes providing them with the resources they need to perform their jobs effectively and providing them with the support they need to succeed.

- Hire, train, and evaluate repair technicians.

- Provide repair technicians with the resources they need.

- Provide repair technicians with the support they need.

3. Ensure that all items are repaired to a high standard

This includes inspecting all repaired items to ensure that they meet the required quality standards. It also includes providing feedback to repair technicians on their work and providing them with the training they need to improve their skills.

- Inspect all repaired items to ensure that they meet the required quality standards.

- Provide feedback to repair technicians on their work.

- Provide repair technicians with the training they need to improve their skills.

4. Meet specified timeframes for repairs

This includes working with customers to set realistic expectations and ensuring that all repairs are completed within the agreed-upon timeframes. It also includes tracking the progress of repairs and taking corrective action if any repairs are falling behind schedule.

- Work with customers to set realistic expectations.

- Ensure that all repairs are completed within the agreed-upon timeframes.

- Track the progress of repairs.

- Take corrective action if any repairs are falling behind schedule.

5. Manage the budget for the repair department

This includes planning and managing the budget for the repair department. It also includes tracking expenses and ensuring that the budget is not exceeded. It also includes identifying opportunities to save money and improve the efficiency of the repair department.

- Plan and manage the budget for the repair department.

- Track expenses.

- Ensure that the budget is not exceeded.

- Identify opportunities to save money.

- Improve the efficiency of the repair department.

Interview Tips

Interviewing for a job can be a daunting experience, but there are some things you can do to prepare and increase your chances of success. Here are a few tips to help you ace your interview for an Item Repair Manager position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to answer questions about the position and your qualifications.

- Visit the company’s website.

- Read the job description carefully.

- Research the company’s industry and competitors.

- Practice answering common interview questions.

2. Dress professionally

The way you dress for your interview will send a message to the interviewer about your professionalism and attention to detail. Make sure to dress in clean, pressed clothes that are appropriate for a business setting.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing anything too revealing or too casual.

- Be comfortable in what you’re wearing.

3. Be on time

Punctuality is important for any job interview, but it is especially important for a job in the repair industry. Arriving on time shows the interviewer that you are respectful of their time and that you are serious about the position.

- Plan your route to the interview in advance.

- Leave early to give yourself plenty of time to get there.

- If you are running late, call the interviewer to let them know.

- Be apologetic and explain why you are late.

4. Be prepared to answer questions

The interviewer will likely ask you a variety of questions about your experience, skills, and qualifications. Be prepared to answer these questions clearly and concisely. You should also be prepared to ask the interviewer questions about the position and the company.

- Practice answering common interview questions.

- Research the company and the position you are applying for.

- Be prepared to ask the interviewer questions about the position and the company.

- Be honest and genuine in your answers.

5. Follow up after the interview

After the interview, take some time to reflect on how it went. If you think there is anything you could have done better, make a note of it so that you can improve for your next interview. You should also follow up with the interviewer to thank them for their time and to express your continued interest in the position.

- Send a thank-you note to the interviewer.

- Express your continued interest in the position.

- Mention anything you could have done better in the interview.

- Be patient and wait for the interviewer to contact you.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Item Repair Manager role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.