Are you gearing up for an interview for a Jackscrew Man position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jackscrew Man and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

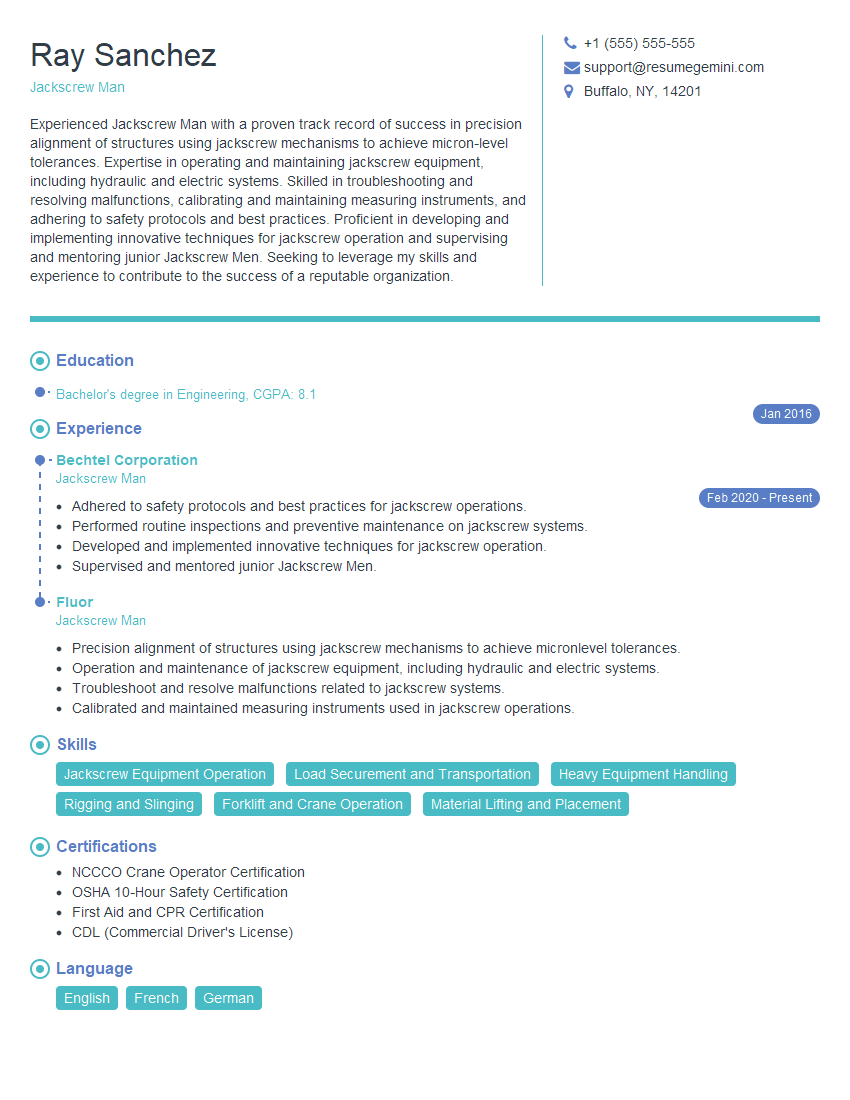

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jackscrew Man

1. Describe the key components of a hydraulic jackscrews system and explain their functions?

The key components of a hydraulic jackscrews system are:

- Hydraulic pump: The pump generates hydraulic pressure, which is the force that drives the system.

- Reservoir: The reservoir stores the hydraulic fluid and provides a constant supply of fluid to the pump.

- Control valve: The control valve regulates the flow of hydraulic fluid to the jackscrews.

- Jackscrews: The jackscrews are the linear actuators that convert hydraulic pressure into linear motion.

- Load: The load is the object that is being lifted or moved by the jackscrews system.

2. How does a hydraulic jackscrews system operate?

A hydraulic jackscrews system operates by converting hydraulic pressure into linear motion.

Operation

- The hydraulic pump generates hydraulic pressure, which is sent to the control valve.

- The control valve directs the hydraulic fluid to the jackscrews.

- The jackscrews convert the hydraulic pressure into linear motion, which is used to lift or move the load.

3. What are the advantages of using a hydraulic jackscrews system?

The advantages of using a hydraulic jackscrews system include:

- High force output: Hydraulic jackscrews systems can generate very high forces, which makes them ideal for lifting or moving heavy loads.

- Precision control: The control valve allows for precise control of the jackscrews system, which is important for applications that require accurate positioning.

- Compact size: Hydraulic jackscrews systems are relatively compact, which makes them ideal for applications where space is limited.

- Low maintenance: Hydraulic jackscrews systems are relatively low-maintenance, which can save on operating costs.

4. What are the disadvantages of using a hydraulic jackscrews system?

The disadvantages of using a hydraulic jackscrews system include:

- Cost: Hydraulic jackscrews systems can be more expensive than other types of lifting systems.

- Complexity: Hydraulic jackscrews systems are more complex than other types of lifting systems, which can make them more difficult to operate and maintain.

- Safety: Hydraulic jackscrews systems can be dangerous if they are not operated and maintained properly.

5. What are some common applications for hydraulic jackscrews systems?

Some common applications for hydraulic jackscrews systems include:

- Lifting heavy loads: Hydraulic jackscrews systems are often used to lift heavy loads, such as machinery, vehicles, and buildings.

- Moving heavy objects: Hydraulic jackscrews systems can also be used to move heavy objects, such as machinery and equipment.

- Positioning heavy objects: Hydraulic jackscrews systems can be used to position heavy objects, such as machinery and equipment, with precision.

- Clamping heavy objects: Hydraulic jackscrews systems can be used to clamp heavy objects, such as machinery and equipment, securely in place.

6. What are the safety considerations when using a hydraulic jackscrews system?

There are several safety considerations when using a hydraulic jackscrews system:

- Use the jackscrews system only for its intended purpose.

- Never exceed the rated capacity of the jackscrews system.

- Inspect the jackscrews system regularly for any signs of damage or wear.

- Never attempt to repair the jackscrews system yourself.

- Always follow the manufacturer’s instructions when operating the jackscrews system.

7. How do you troubleshoot a hydraulic jackscrews system?

There are several steps to troubleshooting a hydraulic jackscrews system:

- Check the hydraulic fluid level.

- Check the hydraulic lines for any leaks.

- Check the control valve for any leaks or obstructions.

- Check the jackscrews for any signs of damage or wear.

- If the problem cannot be identified, contact the manufacturer.

8. What are the different types of hydraulic jackscrews systems?

There are two main types of hydraulic jackscrews systems:

- Single-acting jackscrews systems: Single-acting jackscrews systems use hydraulic pressure to extend the jackscrews. The jackscrews retract under their own weight or by the force of gravity.

- Double-acting jackscrews systems: Double-acting jackscrews systems use hydraulic pressure to extend and retract the jackscrews.

9. What are the factors to consider when selecting a hydraulic jackscrews system?

There are several factors to consider when selecting a hydraulic jackscrews system:

- The load capacity of the jackscrews system.

- The stroke length of the jackscrews system.

- The operating pressure of the jackscrews system.

- The type of hydraulic fluid used in the jackscrews system.

- The environment in which the jackscrews system will be used.

10. What are the latest trends in hydraulic jackscrews systems?

There are several recent trends in hydraulic jackscrews systems:

- The use of higher pressure hydraulic fluids.

- The use of smaller and more compact jackscrews systems.

- The development of new control systems for jackscrews systems.

- The use of jackscrews systems in new applications, such as in robotics and medical devices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jackscrew Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jackscrew Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jackscrew Men are responsible for installing, operating, and maintaining jackscrew equipment. They work in a variety of industries, including construction, shipbuilding, and manufacturing.

1. Equipment Installation

Jackscrew Men are responsible for installing jackscrew equipment according to the manufacturer’s specifications.

- Lay out and assemble jackscrew components, such as bases, jacks, and motors

- Install and connect electrical and hydraulic lines

- Test and calibrate jackscrew equipment to ensure proper operation

2. Equipment Operation

Jackscrew Men are responsible for operating jackscrew equipment to lift and move heavy objects.

- Operate jackscrew equipment to lift and lower objects

- Control the speed and movement of objects being lifted

- Monitor jackscrew equipment for any signs of damage or malfunction

3. Equipment Maintenance

Jackscrew Men are responsible for maintaining jackscrew equipment to ensure its proper operation.

- Inspect jackscrew equipment for any signs of wear or damage

- Lubricate and adjust jackscrew equipment as needed

- Perform minor repairs to jackscrew equipment

4. Safety

Jackscrew Men are responsible for following all safety procedures while working with jackscrew equipment.

- Wear appropriate safety gear, such as hard hats and safety glasses

- Follow proper lifting techniques

- Be aware of the hazards of working with heavy equipment

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the position you’re interviewing for. This will help you understand the company’s culture and values, and it will also help you answer questions about your qualifications and experience.

- Visit the company’s website

- Read articles about the company in industry publications

- Talk to people who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practicing answering these questions ahead of time will help you feel more confident and prepared during your interview.

- Write out your answers to common interview questions

- Practice answering these questions aloud

- Get feedback from a friend or family member

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture.

- Choose clothes that are comfortable and that you can move around in easily

- Avoid wearing clothes that are too revealing or too casual

- Make sure your clothes are clean and pressed

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call or email the interviewer to let them know.

- Plan your route to the interview in advance

- Leave early to give yourself plenty of time to get there

- If you’re running late, call or email the interviewer to let them know

5. Be yourself

The most important thing is to be yourself during your interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just relax and be yourself, and let the interviewer see your personality and skills.

- Be confident in your abilities

- Be honest and authentic

- Let the interviewer see your personality

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jackscrew Man interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!