Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Jackscrew Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

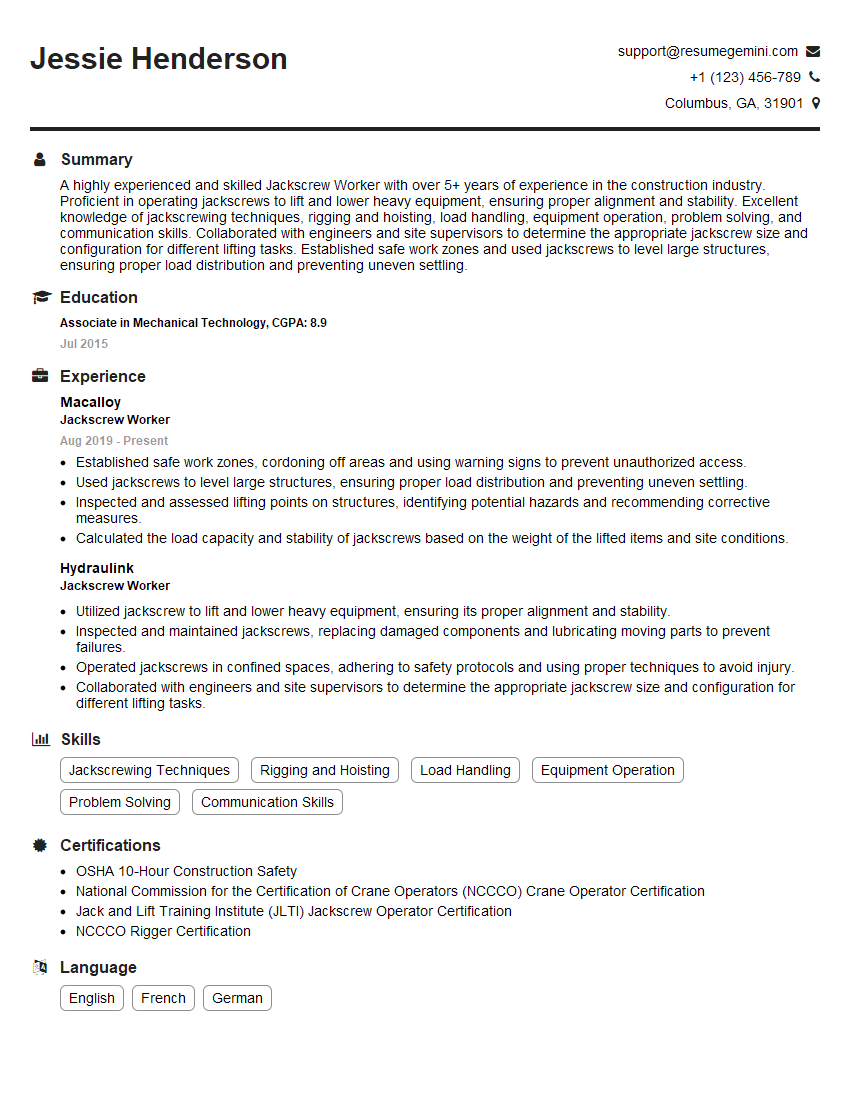

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jackscrew Worker

1. Describe the principles of operation and construction of a jackscrew?

- A jackscrew is a simple machine that uses a screw to lift or lower a heavy load.

- It consists of a screw, a nut, and a frame.

- The screw is turned by a handle, which causes the nut to move up or down the screw.

- The nut is attached to the load, so as the nut moves, the load is lifted or lowered.

- Jackscrews are often used in construction, automotive repair, and other applications where heavy loads need to be lifted or lowered.

2. What are the different types of jackscrews?

Mechanical jackscrews

- Mechanical jackscrews are the most common type of jackscrew.

- They use a simple screw and nut mechanism to lift or lower a load.

Hydraulic jackscrews

- Hydraulic jackscrews use a hydraulic cylinder to lift or lower a load.

- They are more powerful than mechanical jackscrews, but they are also more complex and expensive.

Electric jackscrews

- Electric jackscrews use an electric motor to turn the screw.

- They are the most convenient type of jackscrew, but they are also the most expensive.

3. What are the factors that affect the efficiency of a jackscrew?

- The efficiency of a jackscrew is affected by several factors, including:

- The pitch of the screw

- The diameter of the screw

- The coefficient of friction between the screw and the nut

- The load being lifted or lowered

4. How do you calculate the mechanical advantage of a jackscrew?

- The mechanical advantage of a jackscrew is the ratio of the output force to the input force.

- It can be calculated using the following formula:

- Mechanical advantage = Output force / Input force

5. What are the safety precautions that should be taken when using a jackscrew?

- When using a jackscrew, it is important to take the following safety precautions:

- Always inspect the jackscrew before using it to make sure that it is in good working condition.

- Never overload the jackscrew.

- Always use a jackstand to support the load when using a jackscrew.

- Never leave a jackscrew unattended while it is under load.

6. What are the applications of jackscrews?

- Jackscrews are used in a variety of applications, including:

- Construction

- Automotive repair

- Manufacturing

- Aerospace

- Medical

7. What is the difference between a jackscrew and a worm gear?

- A jackscrew is a simple machine that uses a screw to lift or lower a load.

- A worm gear is a type of gear that is used to transmit motion between two shafts that are perpendicular to each other.

- Jackscrews are typically used for lifting or lowering heavy loads, while worm gears are typically used for transmitting motion.

8. What materials are jackscrews made of?

- Jackscrews are typically made of steel, but they can also be made of other materials, such as aluminum, bronze, or stainless steel.

- The material of the jackscrew will depend on the application and the load that it will be used to lift or lower.

9. What is the maximum load that a jackscrew can lift?

- The maximum load that a jackscrew can lift will depend on the size and type of the jackscrew.

- Small jackscrews can lift a few hundred pounds, while large jackscrews can lift several tons.

10. How do you maintain a jackscrew?

- To maintain a jackscrew, it is important to:

- Keep it clean and free of debris.

- Lubricate the screw and nut regularly.

- Inspect the jackscrew regularly for any signs of wear or damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jackscrew Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jackscrew Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jackscrew Workers perform a variety of tasks related to the operation and maintenance of jackscrew systems used in various industrial and construction settings.

1. Operating Jackscrew Systems

Operate jackscrew systems to lift, lower, and move heavy loads, ensuring their stability and proper functioning.

- Read and interpret blueprints, work orders, and other technical documentation to determine jackscrew system specifications.

- Set up and position jackscrew systems according to specifications, ensuring proper alignment and safety.

2. Maintaining Jackscrew Systems

Perform regular maintenance and inspections on jackscrew systems to ensure their optimal performance and safety.

- Inspect jackscrew components for wear, damage, and proper lubrication.

- Lubricate and adjust jackscrew systems as needed to maintain smooth operation.

3. Troubleshooting and Repairing Jackscrew Systems

Troubleshoot and repair jackscrew systems quickly and efficiently to minimize downtime and ensure safety.

- Diagnose and identify the source of malfunctions or breakdowns in jackscrew systems.

- Replace or repair damaged components and adjust settings to restore proper system operation.

4. Safety Procedures

Follow all safety protocols and regulations related to jackscrew operations, including personal protective equipment (PPE) and risk assessment.

- Inspect and maintain PPE and safety equipment used in jackscrew operations.

- Conduct risk assessments and implement safety measures to prevent accidents and injuries.

Interview Tips

Preparing for a jackscrew worker interview requires a combination of technical knowledge and understanding of safety procedures. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Research the company you’re applying to and the industry it operates in. This will give you a solid understanding of their business, values, and safety practices.

- Visit the company’s website and social media pages to learn about their work, culture, and team.

- Read industry publications and news articles to stay up-to-date on trends and best practices in jackscrew operations.

2. Practice Your Technical Skills

Review the technical aspects of jackscrew operations and safety procedures. Practice answering questions about jackscrew system components, troubleshooting techniques, and safety regulations.

- Use online resources, textbooks, or training materials to refresh your knowledge and practice your skills.

- Consider preparing a portfolio or showcasing your previous work experience in jackscrew operations.

3. Highlight Your Safety Mindset

Emphasize your understanding of safety procedures and your commitment to working safely. Explain how you prioritize safety in your work and how you handle potential hazards.

- Describe your experience with safety training and compliance in previous roles.

- Share examples of how you identified and mitigated risks in jackscrew operations.

4. Demonstrate Your Problem-Solving Abilities

Jackscrew workers often encounter challenges and problems on the job. Highlight your problem-solving skills and ability to work effectively under pressure.

- Describe a situation where you successfully diagnosed and resolved a problem with a jackscrew system.

- Explain how you prioritize tasks and manage multiple responsibilities in a fast-paced environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Jackscrew Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Jackscrew Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.