Are you gearing up for an interview for a Jacquard Plate Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jacquard Plate Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

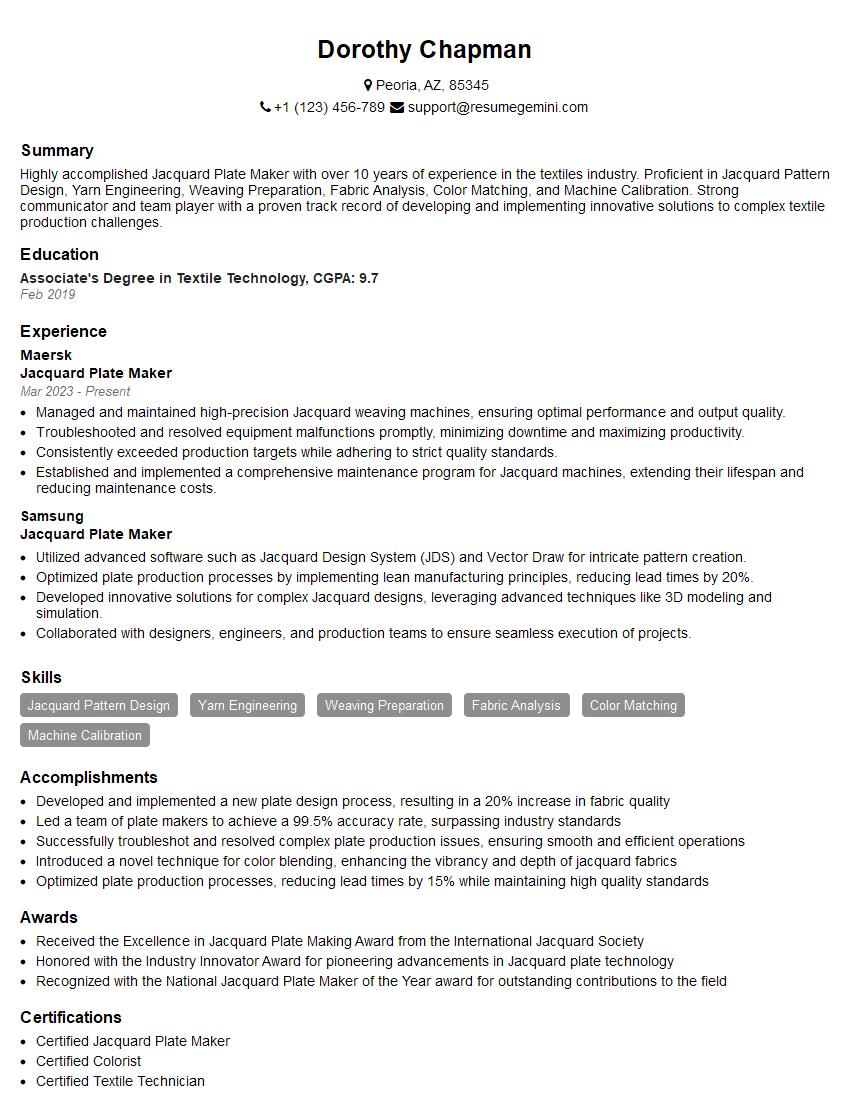

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jacquard Plate Maker

1. What are the different types of Jacquard looms and their applications?

The different types of Jacquard looms include:

- Flat Jacquard loom: Used for weaving small, intricate patterns on fabrics. Suitable for high-volume production and complex designs.

- Rotary Jacquard loom: Employs a rotating mechanism to control warp threads. Offers higher efficiency and higher speeds compared to flat looms.

- Barrel Jacquard loom: Uses a cylindrical barrel to control warp threads. Suitable for weaving large patterns or designs across the fabric’s width.

- Electronic Jacquard loom: Utilizes electronic controls to operate the loom. Provides precise control over weaving, allowing for complex and detailed patterns.

2. Explain the process of creating a Jacquard plate design.

Design Creation:

- Develop the desired pattern using specialized software.

- Translate the pattern into a series of punching instructions.

Plate Preparation:

- Cut a set of Jacquard cards based on the punching instructions.

- Assemble the cards into a chain, representing the pattern sequence.

- Punch holes in a blank plate according to the card chain.

3. What are the key factors that affect the quality of a Jacquard plate?

- Hole precision: Accuracy of punched holes ensures proper warp selection.

- Hole alignment: Correct alignment of holes allows for smooth operation of the loom.

- Card chain accuracy: Proper sequencing of cards is critical for accurate pattern reproduction.

- Plate material: Durability and rigidity of the plate are crucial for extended usage.

4. Describe the maintenance and troubleshooting procedures for Jacquard plates.

Maintenance:

- Regular cleaning to remove dust and debris.

- Periodic inspection for wear or damage.

- Proper storage to prevent bending or warping.

Troubleshooting:

- Inspect cards and plate for alignment issues.

- Check for blocked or broken holes.

- Analyze fabric samples to identify pattern defects.

5. What are the advantages of using electronic Jacquard looms over traditional mechanical looms?

- Increased efficiency and speed.

- Reduced setup time for pattern changes.

- Improved pattern precision and repeatability.

- Capability to create complex and intricate designs.

- Integration with computer-aided design (CAD) software.

6. Describe the role of software in Jacquard plate making.

- Design development and translation into punching instructions.

- Automated punching and plate creation.

- Simulation of weaving patterns before plate production.

- Data storage and management for patterns and designs.

- Integration with other production systems.

7. How do you ensure color accuracy in Jacquard weaving?

- Proper selection of yarn colors based on pattern requirements.

- Calibration of loom to achieve consistent color reproduction.

- Careful monitoring of yarn tension and weaving conditions.

- Use of color correction techniques, if necessary.

- Communication with the design team to match intended colors.

8. What are the latest trends and innovations in Jacquard plate making?

- 3D Jacquard weaving for creating textured patterns.

- Digital Jacquard systems for increased flexibility and customization.

- Integration of artificial intelligence (AI) for design optimization.

- Use of sustainable materials in plate production.

- Development of virtual reality (VR) tools for design visualization.

9. How do you stay updated with the latest advancements in Jacquard technology?

- Attend industry conferences and exhibitions.

- Read technical journals and industry publications.

- Participate in online forums and discussions.

- Collaborate with fabric manufacturers and designers.

- Engage in continuous professional development courses.

10. What is your approach to quality control in Jacquard plate making?

- Establish clear quality standards and specifications.

- Conduct thorough inspections at each stage of production.

- Utilize advanced measuring and testing equipment.

- Document quality checks and record any defects or deviations.

- Implement corrective measures to address quality issues promptly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jacquard Plate Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jacquard Plate Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jacquard plate makers play a pivotal role in the textile industry, creating intricate designs for woven fabrics. Their primary duties involve:

1. Pattern Creation and Design

Using specialized software or traditional drafting methods, jacquard plate makers translate design concepts into detailed patterns. They ensure that designs align with fabric weave structures and meet quality standards.

- Convert artwork and design specifications into technical patterns

- Adjust and refine patterns to optimize fabric production

2. Plate Preparation and Production

Jacquard plate makers prepare weaving plates based on the designed patterns. They use precision equipment and techniques to create holes or perforations on the plates that control the lifting and lowering of warp threads during the weaving process.

- Select appropriate materials and plate sizes based on fabric requirements

- Punch or drill holes into the plates according to the pattern

- Inspect plates for accuracy and quality before mounting on the weaving machine

3. Machine Setup and Operation

Jacquard plate makers ensure that weaving machines are properly set up and calibrated for specific designs and fabrics. They may also operate the machines to produce woven samples or small-scale productions.

- Mount prepared plates on the weaving machine

- Adjust machine settings to match pattern requirements

- Monitor the weaving process to identify and address any issues

4. Quality Assurance

Jacquard plate makers conduct quality checks throughout the process, ensuring that plates and woven fabrics meet specifications. They identify and correct errors to maintain high standards of production.

- Inspect plates for defects or inaccuracies

- Evaluate woven samples for design accuracy and fabric quality

- Provide feedback to designers and production teams for continuous improvement

Interview Tips

To ace an interview for a Jacquard plate maker position, candidates should consider the following tips:

1. Research the Industry and Company

Familiarize yourself with the latest trends in the textile industry and the specific company you are applying to. Research their product offerings, customer base, and any recent innovations.

- Read industry publications and articles

- Visit the company website and social media pages

- Network with professionals in the field

2. Highlight Technical Skills and Experience

Emphasize your proficiency in pattern creation, plate preparation, and machine operation. Quantify your experience with specific examples and provide evidence of your attention to detail and quality orientation.

- Describe projects where you developed complex patterns and produced high-quality woven fabrics

- Mention any certifications or training programs you have completed

- Showcase your understanding of different weaving techniques and fabric structures

3. Demonstrate Problem-Solving Abilities

Interviewers will be impressed by candidates who can demonstrate their problem-solving skills and ability to handle unexpected challenges. Discuss situations where you identified and resolved issues related to pattern design, plate production, or machine operation.

- Explain how you troubleshoot and repair faulty plates

- Share examples of how you optimized designs to minimize fabric defects

- Describe your experience in collaborating with other team members to address production issues

4. Emphasize Communication and Teamwork

Collaboration is essential in a textile production environment. Highlight your communication and teamwork skills, emphasizing your ability to effectively interact with designers, engineers, and production staff.

- Describe your experience in working with design teams to translate concepts into workable patterns

- Explain how you communicate technical information clearly and concisely

- Discuss your contributions to team projects and the outcomes achieved

5. Prepare Questions for the Interviewer

Asking insightful questions at the end of the interview demonstrates your interest and enthusiasm for the position. Prepare thoughtful questions related to the company’s production processes, innovation initiatives, or industry trends.

- Inquire about the company’s investment in research and development

- Ask about opportunities for professional development and advancement

- Express interest in the company’s sustainability practices

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jacquard Plate Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.