Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Jamb Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

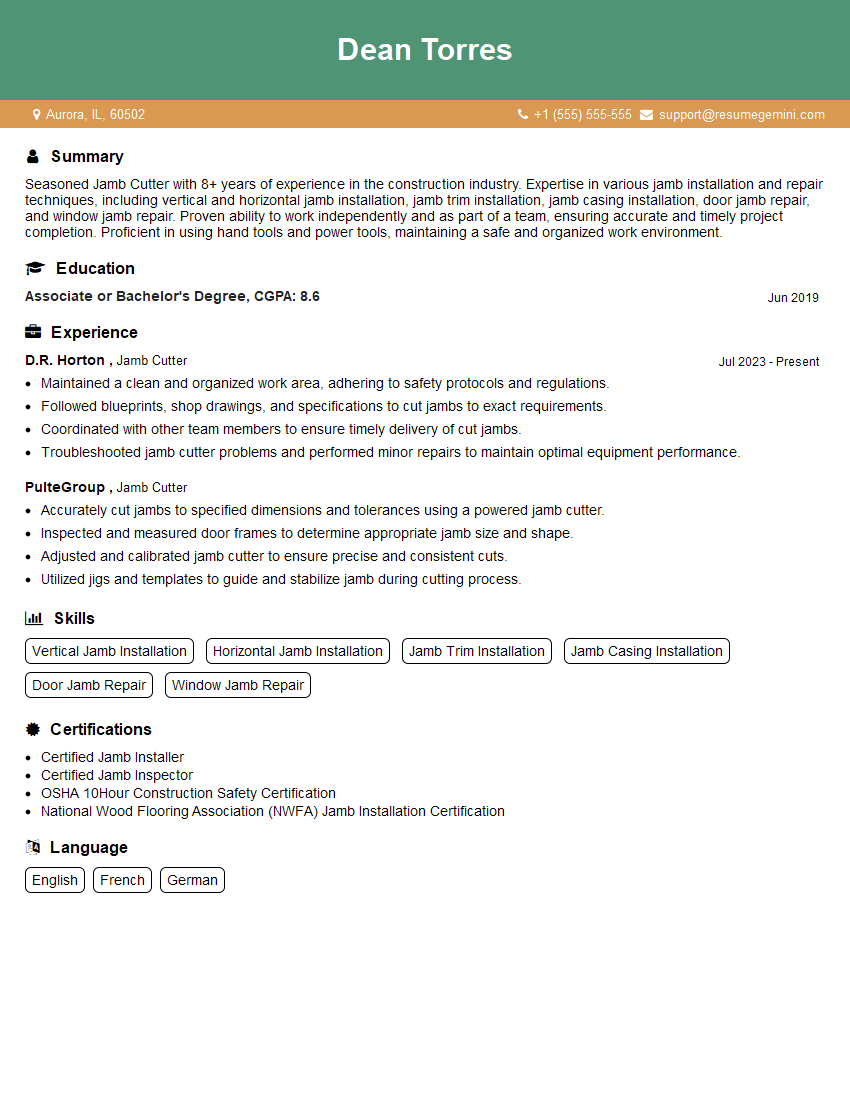

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jamb Cutter

1. What are the different types of jamb saws available?

There are several types of jamb saws, including:

- Hand jamb saws: These saws are manually operated and feature a thin, flexible blade that can be used to cut through jambs and other thin materials.

- Power jamb saws: These saws are powered by an electric motor and feature a rotating blade that can be used to cut through jambs and other materials quickly and efficiently.

- Oscillating jamb saws: These saws use a reciprocating motion to cut through jambs and other materials, making them ideal for cutting in tight spaces or around obstacles.

2. What are the key features to consider when selecting a jamb saw?

Blade type

- Different types of jamb saws use different blade types. Consider the material you’ll be cutting and choose a blade that is appropriate for the job.

Power source

- Jamb saws can be either manual or powered. Manual jamb saws require more effort to use but are more portable. Powered jamb saws are faster and more efficient but require an electrical outlet.

Size and weight

- The size and weight of a jamb saw can be important considerations, especially if you’ll be using it for extended periods.

3. How do you use a jamb saw safely?

To use a jamb saw safely, follow these steps:

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Ensure that the jamb saw is in good working condition.

- Secure the material you are cutting to prevent it from moving.

- Hold the jamb saw firmly and guide it through the material.

- Be aware of your surroundings and avoid cutting near electrical cords or other hazards.

4. What are some tips for cutting jambs accurately?

To cut jambs accurately, follow these tips:

- Measure the jamb opening carefully and mark the cut lines.

- Use a sharp blade and make sure the jamb saw is properly aligned.

- Cut slowly and carefully, following the marked lines.

- Check the fit of the jamb before installing it.

5. What is the best way to maintain a jamb saw?

To maintain a jamb saw, follow these steps:

- Clean the jamb saw after each use.

- Oil the moving parts regularly.

- Inspect the blade for damage and replace it if necessary.

- Store the jamb saw in a dry place.

6. What are the common problems that can occur when using a jamb saw?

Some common problems that can occur when using a jamb saw include:

- The blade can become dull or damaged.

- The jamb saw can become clogged with sawdust.

- The jamb saw can overheat.

- The jamb saw can vibrate excessively.

7. How do you troubleshoot a jamb saw that is not cutting properly?

If your jamb saw is not cutting properly, you can troubleshoot the issue by following these steps:

- Check the blade for damage and replace it if necessary.

- Clean the jamb saw and remove any sawdust or debris.

- Check the alignment of the jamb saw and make sure it is properly adjusted.

- If the jamb saw is overheating, allow it to cool down before continuing to use it.

- If the jamb saw is vibrating excessively, check the blade for damage and make sure the jamb saw is properly balanced.

8. What are the different types of jambs?

There are several different types of jambs, including:

- Wood jambs: Wood jambs are the most common type of jamb and are available in a variety of styles and finishes.

- Metal jambs: Metal jambs are durable and fire-resistant, making them a good choice for commercial applications.

- Fiberglass jambs: Fiberglass jambs are lightweight and weather-resistant, making them a good choice for exterior applications.

9. How do you install a jamb?

To install a jamb, follow these steps:

- Measure the opening and cut the jamb to the appropriate size.

- Apply a bead of sealant to the back of the jamb.

- Position the jamb in the opening and secure it with nails or screws.

- Caulk around the edges of the jamb to seal it.

10. What are the common problems that can occur when installing a jamb?

Some common problems that can occur when installing a jamb include:

- The jamb may not be the correct size for the opening.

- The jamb may not be level or plumb.

- The jamb may not be properly sealed, allowing air or water to leak through.

- The jamb may be damaged during installation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jamb Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jamb Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jamb Cutters are responsible for operating jamb cutting machines to cut and shape door and window frames. These professionals typically work in construction and manufacturing environments, and their duties may include:

1. Machine Operation

Jamb Cutters are responsible for operating jamb cutting machines to cut and shape door and window frames. They must be able to set up and operate the machine, as well as troubleshoot any problems that arise.

- Set up and operate jamb cutting machines

- Calibrate and maintain cutting equipment

- Cut and shape door and window frames to specifications

2. Material Handling

Jamb Cutters are responsible for handling materials, such as wood and plastic. They must be able to safely lift and move heavy materials, as well as load and unload materials.

- Load and unload materials from cutting machines

- Move materials around the work area

- Dispose of waste materials

3. Quality Control

Jamb Cutters are responsible for ensuring that the quality of their work meets company standards. They must be able to inspect cut parts for accuracy and completeness, as well as identify and correct any defects.

- Inspect cut parts for accuracy and completeness

- Identify and correct defects

- Maintain records of quality control inspections

4. Safety

Jamb Cutters must adhere to all safety regulations and procedures. They must be able to identify and avoid hazards, as well as use personal protective equipment.

- Follow all safety regulations and procedures

- Identify and avoid hazards

- Use personal protective equipment

Interview Tips

Preparing for an interview can be daunting, but taking the time to do your research and prepare thoughtful answers will give you an edge over other candidates. Here are a few tips to help you ace your next Jamb Cutter interview:

1. Research the Company and Position

Before you go into an interview, it’s important to do your research on the company and the position you’re applying for. This will show the interviewer that you’re interested in the job and that you’ve taken the time to learn about the company’s culture and values.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company, if possible

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Prepare answers to common interview questions

- Practice your answers out loud

- Get feedback from a friend or family member

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience, so be prepared to talk about your qualifications in detail. Highlight your strengths and how they relate to the job requirements.

- Review your resume and be prepared to discuss your skills and experience

- Give specific examples of your work

- Quantify your accomplishments whenever possible

4. Ask Questions

Asking questions at the end of an interview is a great way to show the interviewer that you’re interested in the job and that you’re taking the interview seriously. Prepare a few questions to ask the interviewer about the company, the position, and the work environment.

- Prepare a few questions to ask the interviewer

- Ask about the company culture

- Ask about the training and development opportunities

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jamb Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.