Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Jet Engine Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Jet Engine Mechanic so you can tailor your answers to impress potential employers.

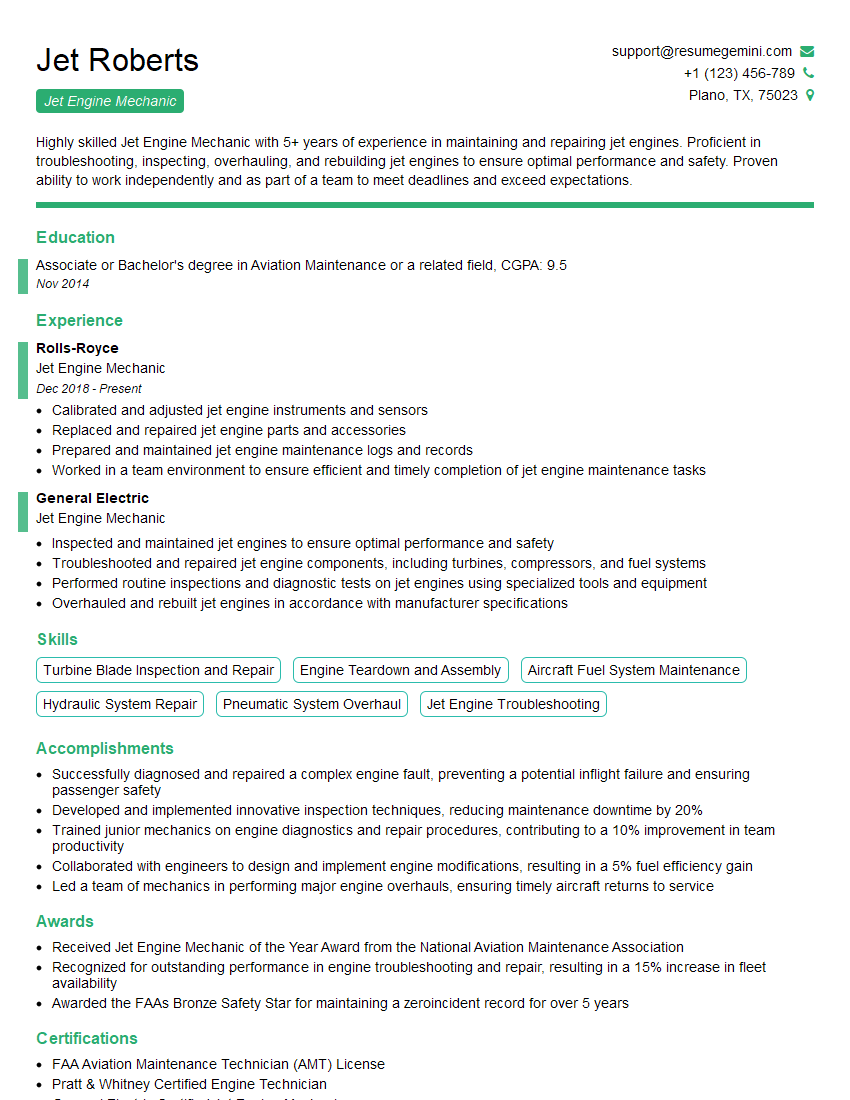

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jet Engine Mechanic

1. Describe the steps involved in troubleshooting a jet engine that is experiencing compressor stalls?

During a compressor stall, airflow separation occurs within the compressor, leading to reduced engine thrust and efficiency. Troubleshooting involves:

- Identify symptoms: Reduced thrust, increased exhaust gas temperature (EGT), and compressor pressure ratio (CPR) fluctuations.

- Check inlet conditions: Inspect for foreign object damage (FOD), icing, or bird strikes.

- Bleed system: Verify correct operation of bleed valves and ensure proper bleed flow.

- Variable geometry: Check the operation of variable inlet guide vanes (IGVs) or variable stators for proper opening and closing.

- Engine health: Monitor engine parameters such as EGT, fuel flow, and RPM to identify any underlying issues.

2. Explain the concept of thrust augmentation and how it is achieved in a jet engine?

Afterburner

- Injects additional fuel into the exhaust stream.

- Burns the fuel to increase exhaust gas temperature and velocity.

- Produces significant thrust augmentation, but also increases fuel consumption.

Water injection

- Injects water into the compressor inlet.

- Evaporates and cools the incoming air, increasing its density.

- Increases mass flow through the engine, resulting in thrust augmentation.

3. How do you perform a borescope inspection on a jet engine?

Preparation:

- Obtain appropriate borescope equipment and cleaning supplies.

- Ensure engine is cool and safe for inspection.

Inspection procedure:

- Insert borescope into designated inspection ports.

- Illuminate and visually examine internal components.

- Capture images or videos for documentation.

- Inspect for cracks, wear, corrosion, or other abnormalities.

4. Describe the different types of non-destructive testing (NDT) methods used for jet engine components?

- Ultrasonic testing (UT): Uses high-frequency sound waves to detect flaws and cracks.

- Radiographic testing (RT): Uses X-rays or gamma rays to create images and identify defects.

- Eddy current testing (ET): Uses electromagnetic fields to detect surface cracks and corrosion.

- Magnetic particle testing (MT): Uses magnetic fields and ferromagnetic particles to locate surface or near-surface cracks.

- Dye penetrant testing (PT): Uses a dye to penetrate and highlight surface defects.

5. How do you ensure proper lubrication and cooling of a jet engine?

- Lubrication system: Delivers oil to bearings, gears, and other moving parts to reduce friction and prevent wear.

- Cooling system: Utilizes air or liquid to dissipate heat from engine components, preventing overheating.

- Oil analysis: Regular monitoring of oil condition to detect any contamination, degradation, or metal particles that may indicate potential issues.

6. Explain the role of fuel metering in jet engine performance?

Fuel metering ensures the engine receives the correct amount of fuel to operate efficiently and safely:

- Fuel control system: Regulates fuel flow based on engine parameters such as RPM, pressure, and temperature.

- Fuel injectors: Atomize and spray fuel into the combustion chamber at the correct time and quantity.

- Burner nozzles: Shape and mix the fuel spray for optimal combustion.

7. How do you handle and store hazardous materials used in jet engine maintenance?

Safe handling:

- Wear appropriate personal protective equipment (PPE).

- Follow specified mixing and application procedures.

- Avoid contact with skin and eyes.

Storage:

- Store in a dedicated, well-ventilated area.

- Comply with local and federal regulations.

- Dispose of hazardous waste properly.

8. Describe the different types of engine mounts used in jet aircraft?

- Rigid mounts: Fix the engine directly to the airframe, providing stability and reducing vibration.

- Flexible mounts: Use rubber or elastomeric materials to absorb and isolate engine vibrations from the airframe.

- Dynafocal mounts: Combine rigid and flexible elements to provide vibration isolation and ensure structural integrity.

9. How do you perform a fuel leak test on a jet engine?

- Visual inspection: Check for any visible leaks or signs of fuel pooling.

- Fuel pressure test: Apply pressure to the fuel system and check for leaks using a pressure gauge or soapy water solution.

- Dye penetrant test: Apply a dye to potential leak areas and inspect for any traces of dye that indicate a leak.

10. What are the key considerations when performing maintenance on a jet engine bleed air system?

- Safety: Bleed air is high-pressure and high-temperature, requiring proper PPE and precautions.

- Isolation: Disconnect the bleed air system from the aircraft prior to maintenance.

- Inspection: Inspect for leaks, blockages, and damage to hoses, valves, and other components.

- Testing: Perform functional tests to ensure proper operation of the bleed air system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jet Engine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jet Engine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jet Engine Mechanics are responsible for the maintenance, repair and overhaul of jet engines. They work on a variety of aircraft, from small private planes to large commercial airliners. Their duties include:

1. Inspecting and Testing Engines

Jet Engine Mechanics begin by inspecting engines for any signs of damage or wear. They also perform tests to ensure that the engines are operating properly.

2. Repairing and Overhauling Engines

If an engine is damaged or worn, Jet Engine Mechanics will repair or overhaul it. This may involve replacing parts, welding, or machining.

3. Installing and Removing Engines

Jet Engine Mechanics may also be responsible for installing and removing engines from aircraft.

4. Troubleshooting and Diagnosing Engine Problems

If an engine is not operating properly, Jet Engine Mechanics will troubleshoot and diagnose the problem. They will then make the necessary repairs or adjustments.

5. Maintaining Records

Jet Engine Mechanics must keep detailed records of all work performed on engines. These records are used to track the maintenance history of the engines and to help identify any potential problems.

Interview Tips

To ace an interview for a Jet Engine Mechanic position, it is important to be prepared. Here are a few tips:

1. Research the Company and the Position

Before you go to an interview, do some research on the company and the position. This will help you understand the company’s culture and what they are looking for in a candidate.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you can expect to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience working on jet engines. Be prepared to talk about your specific skills and knowledge.

4. Be Prepared for Technical Questions

The interviewer may also ask you technical questions about jet engines. Be prepared to answer these questions to the best of your ability.

5. Be Enthusiastic and Professional

Show the interviewer that you are enthusiastic about the position and that you are a professional. Dress appropriately and arrive on time for your interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Jet Engine Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Jet Engine Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.