Are you gearing up for an interview for a Jetting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jetting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

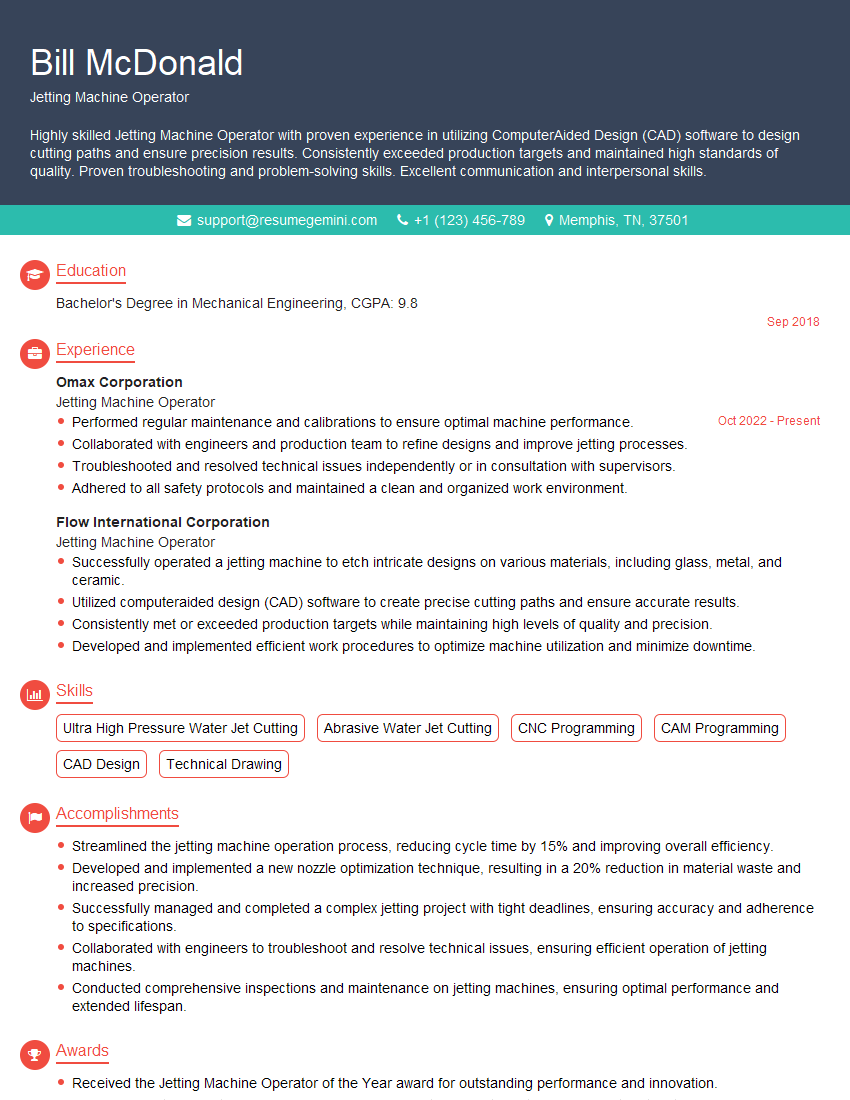

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jetting Machine Operator

1. Explain the process of jetting in detail.

- Jetting is a process of removing material from a workpiece using a high-pressure stream of water or other fluid.

- The jet of water is directed at the workpiece surface, and the force of the water removes the material.

- Jetting can be used to remove a variety of materials, including metal, plastic, and wood.

2. What are the different types of jetting machines?

- There are two main types of jetting machines: water jet cutters and abrasive water jet cutters.

- Water jet cutters use a jet of water to remove material, while abrasive water jet cutters use a jet of water mixed with abrasive particles.

- Abrasive water jet cutters can remove harder materials than water jet cutters.

3. What are the advantages and disadvantages of jetting?

Advantages of jetting

- Jetting is a precise process that can be used to create complex shapes.

- Jetting does not produce any heat, so it can be used to cut heat-sensitive materials.

- Jetting is a relatively clean process, and it does not produce any hazardous waste.

Disadvantages of jetting

- Jetting can be a slow process, especially when cutting thick materials.

- Jetting can be expensive, especially when using abrasive water jet cutters.

- Jetting can create a lot of noise, so it is important to use hearing protection when operating a jetting machine.

4. What are the safety precautions that must be taken when operating a jetting machine?

- Always wear safety glasses and hearing protection when operating a jetting machine.

- Never put your hands or any other body parts near the jet stream.

- Keep the work area clean and free of debris.

- Never operate a jetting machine under the influence of alcohol or drugs.

5. What are the different applications of jetting?

- Jetting is used in a variety of applications, including:

- Cutting metal, plastic, and wood

- Cleaning surfaces

- Removing coatings

- Etching

6. What are the maintenance requirements for a jetting machine?

- Jetting machines require regular maintenance to keep them running properly.

- Some of the maintenance tasks that need to be performed include:

- Cleaning the water filter

- Replacing the water pump

- Calibrating the machine

7. What are the troubleshooting tips for jetting machines?

- If a jetting machine is not working properly, there are a few troubleshooting tips that can be tried:

- Check the water filter and replace it if necessary.

- Check the water pump and replace it if necessary.

- Calibrate the machine.

- If the problem persists, contact a qualified technician.

8. What is the difference between a jetting machine and a water jet cutter?

- A jetting machine is a general term for any machine that uses a high-pressure stream of water to remove material.

- A water jet cutter is a specific type of jetting machine that uses a jet of water to cut materials.

- Water jet cutters are typically more precise than other types of jetting machines, and they can be used to cut a wider variety of materials.

9. What is the difference between a water jet cutter and an abrasive water jet cutter?

- A water jet cutter uses a jet of water to cut materials.

- An abrasive water jet cutter uses a jet of water mixed with abrasive particles to cut materials.

- Abrasive water jet cutters can cut harder materials than water jet cutters.

10. What are the different types of abrasive materials used in abrasive water jet cutting?

- The most common types of abrasive materials used in abrasive water jet cutting are garnet, aluminum oxide, and silicon carbide.

- Garnet is a natural mineral that is very hard and durable.

- Aluminum oxide is a synthetic material that is also very hard and durable.

- Silicon carbide is a synthetic material that is even harder than garnet and aluminum oxide.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jetting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jetting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jetting Machine Operators are responsible for operating and maintaining high-pressure water jetting machines, which are used to clean surfaces and remove debris. Key job responsibilities include:

1. Machine Operation

Operate high-pressure water jetting machines to clean and remove debris from various surfaces, including buildings, bridges, and equipment.

- Set up and calibrate equipment according to job specifications.

- Control water pressure, flow rate, and nozzle angle to achieve desired cleaning results.

2. Machine Maintenance

Perform routine maintenance and repairs on jetting machines to ensure optimal performance.

- Inspect equipment for wear and tear, and replace or repair components as needed.

- Lubricate moving parts and clean filters to maintain machine efficiency.

3. Safety and Compliance

Follow safety protocols and industry regulations when operating jetting machines.

- Wear appropriate protective gear, including gloves, safety glasses, and hearing protection.

- Follow lockout/tagout procedures to prevent accidents during maintenance.

4. Communication and Recordkeeping

Communicate with supervisors and colleagues to discuss work assignments and resolve any issues.

- Maintain accurate records of equipment maintenance and cleaning operations.

- Report any equipment malfunctions or safety concerns to management promptly.

Interview Tips

To help you ace your interview for a Jetting Machine Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and industry standing. Research the specific jetting machine operator role and its responsibilities.

- Visit the company website and LinkedIn page.

- Read industry news and articles to stay informed about the latest trends.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in operating and maintaining high-pressure water jetting machines.

- Quantify your accomplishments using specific metrics.

- Be prepared to discuss your knowledge of safety protocols and industry regulations.

3. Demonstrate Your Safety Consciousness

Interviewers will be keen on assessing your understanding of safety procedures and your commitment to working safely.

- Explain your experience in following lockout/tagout procedures.

- Discuss any safety initiatives you have implemented or participated in.

4. Be Enthusiastic and Professional

Convey your enthusiasm for the jetting machine operator role and your eagerness to contribute to the company.

- Maintain eye contact and speak clearly and confidently.

- Dress professionally and arrive on time for your interview.

Next Step:

Now that you’re armed with the knowledge of Jetting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Jetting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini