Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Jewel Bearing Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

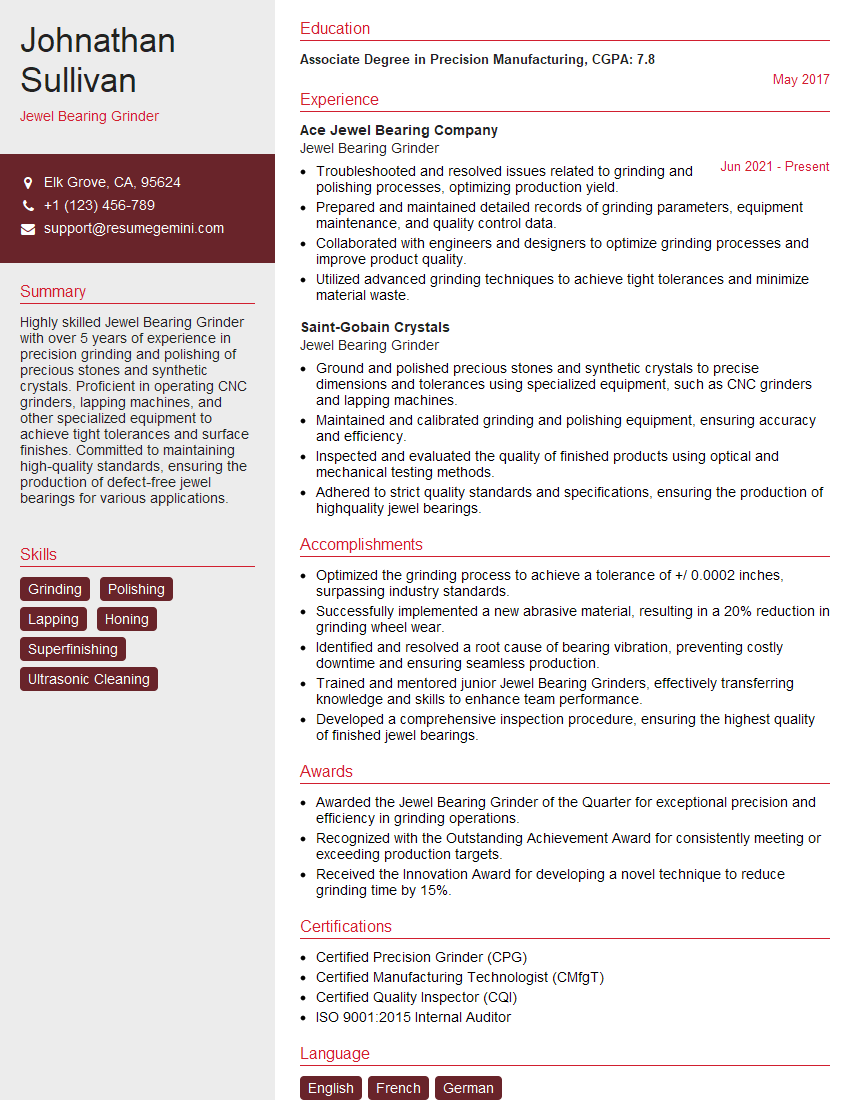

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewel Bearing Grinder

1. Explain the process of grinding a jewel bearing?

- The process of grinding a jewel bearing involves several steps, including:

- Lapping: This is the initial stage of grinding, where the bearing is shaped using a coarse abrasive material.

- Pre-polishing: The bearing is then pre-polished using a finer abrasive material to remove any remaining roughness.

- Polishing: The final step involves polishing the bearing using a very fine abrasive material to achieve the desired surface finish.

- Quality Control: Throughout the process, the bearing is regularly inspected to ensure that it meets the required specifications.

2. What are the different types of grinding wheels used for jewel bearings?

Abrasive Type

- Diamond

- CBN (Cubic Boron Nitride)

- Al2O3 (Aluminum Oxide)

- SiC (Silicon Carbide)

Bond Type

- Vitrified

- Resinoid

- Metal

- Electroplated

3. What are the factors that affect the grinding process?

- Wheel Selection: The type of grinding wheel used will depend on the material of the bearing, the desired surface finish, and the grinding conditions.

- Grinding Conditions: The grinding speed, feed rate, and depth of cut all need to be carefully controlled to achieve the desired results.

- Coolant: A coolant is used to keep the bearing and the grinding wheel cool and to prevent the formation of burrs.

- Machine Condition: The accuracy and condition of the grinding machine will also affect the quality of the finished product.

4. What are the common defects that can occur during jewel bearing grinding?

- Scratches: Scratches can be caused by using a dull grinding wheel or by grinding at too high a speed.

- Burrs: Burrs are small, raised edges that can be caused by using a worn grinding wheel or by grinding at too low a speed.

- Cracks: Cracks can be caused by using too much force or by grinding in the wrong direction.

- Chips: Chips can be caused by using a dull grinding wheel or by grinding at too high a speed.

- Incorrect Shape: The bearing may not be the correct shape if the grinding wheel is not properly dressed or if the grinding conditions are not correct.

5. How do you maintain and calibrate a jewel bearing grinder?

- Regular Cleaning: The grinder should be cleaned regularly to remove any dust or debris that could interfere with the grinding process.

- Lubrication: The grinder should be lubricated regularly to ensure that all moving parts are operating smoothly.

- Calibration: The grinder should be calibrated regularly to ensure that it is grinding to the correct specifications.

- Wheel Dressing: The grinding wheel should be dressed regularly to remove any wear or damage and to ensure that it is cutting properly.

6. What is the difference between a jewel bearing and a ball bearing?

- Jewel bearings are made of a hard, synthetic material, such as sapphire or ruby, and are used in precision instruments where low friction and high accuracy are required.

- Ball bearings are made of metal and are used in a wide variety of applications, including automotive, industrial, and aerospace.

7. What are the applications of jewel bearings?

- Watches: Jewel bearings are used in watches to reduce friction and wear.

- Clocks: Jewel bearings are used in clocks to reduce friction and wear.

- Meters: Jewel bearings are used in meters to reduce friction and wear.

- Compasses: Jewel bearings are used in compasses to reduce friction and wear.

- Aircraft Instruments: Jewel bearings are used in aircraft instruments to reduce friction and wear.

8. What are the challenges of grinding jewel bearings?

- Material Hardness: Jewel bearings are made of very hard materials, which can make them difficult to grind.

- Precision: Jewel bearings must be ground to very high precision to ensure that they perform properly.

- Fragility: Jewel bearings are relatively fragile and can be easily damaged if they are not handled properly.

- Cost: Jewel bearings are relatively expensive to produce.

9. What are the latest trends in jewel bearing grinding?

- Automated Grinding: Automated grinding machines are becoming increasingly common in the jewel bearing industry.

- Laser Grinding: Laser grinding is a new technology that is being used to grind jewel bearings.

- Ultrasonic Grinding: Ultrasonic grinding is another new technology that is being used to grind jewel bearings.

10. What are the quality standards for jewel bearings?

- ISO: The International Organization for Standardization (ISO) has developed a number of standards for jewel bearings.

- ANSI: The American National Standards Institute (ANSI) has also developed a number of standards for jewel bearings.

- DIN: The Deutsches Institut für Normung (DIN) has also developed a number of standards for jewel bearings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewel Bearing Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewel Bearing Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jewel Bearing Grinder is responsible for grinding and finishing synthetic and natural jewel bearings for use in various precision instruments. These bearings are typically used in applications that require minimal friction and high accuracy. The key job responsibilities of a Jewel Bearing Grinder include:

1. Grinding

Accurately grinding jewel bearings to precise dimensions and tolerances.

- Operating grinding machines and using various grinding tools to achieve the required shape and size of the bearings.

- Measuring and inspecting the bearings throughout the grinding process to ensure adherence to specifications.

2. Finishing

Polishing and finishing the bearings to a high level of precision and surface finish.

- Using specialized finishing techniques and equipment to remove any imperfections or burrs from the bearings.

- Inspecting the bearings to ensure they meet the required surface finish and dimensional tolerances.

3. Quality Control

Maintaining high standards of quality throughout the grinding and finishing process.

- Adhering to established quality control procedures and regulations.

- Conducting regular inspections and testing to ensure the bearings meet the required specifications.

4. Machine Maintenance

Maintaining and calibrating the grinding and finishing machinery.

- Performing routine maintenance and repairs on the equipment to ensure optimal performance.

- Calibrating the equipment to ensure precise grinding and finishing.

Interview Tips

Preparing thoroughly for an interview is essential to make a positive impression and increase your chances of success. Here are some interview tips and hacks that can help you ace your interview for a Jewel Bearing Grinder position:

1. Research the Company and Position

Familiarize yourself with the company’s background, products or services, and the specific requirements of the Jewel Bearing Grinder position. Researching the company will enable you to tailor your answers and demonstrate your interest in the opportunity.

- Visit the company’s website and LinkedIn page.

- Read industry publications and news articles to gain insights.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job responsibilities. Quantify your accomplishments whenever possible to demonstrate your impact.

- Showcase your expertise in grinding and finishing techniques, including the use of specialized equipment.

- Provide examples of your ability to maintain high levels of quality and precision in your work.

3. Demonstrate Your Understanding of the Industry

Discuss your knowledge of the industry and the applications where jewel bearings are used. This will demonstrate your understanding of the context of the role and your ability to contribute effectively.

- Discuss the different types of jewel bearings and their specific uses in various industries.

- Explain the importance of precision and quality in the production of jewel bearings.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions that demonstrate your understanding of the company, the position, and the industry.

- Inquire about the company’s future plans and growth prospects.

- Ask about opportunities for professional development and advancement.

5. Practice and Be Confident

Practice your answers to common interview questions and rehearse your presentation to gain confidence. The more prepared you are, the more composed and articulate you will appear during the interview.

- Conduct mock interviews with a friend or family member to get feedback.

- Visualize yourself successfully completing the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Jewel Bearing Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Jewel Bearing Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.