Feeling lost in a sea of interview questions? Landed that dream interview for Jewel Corner Brushing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Jewel Corner Brushing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

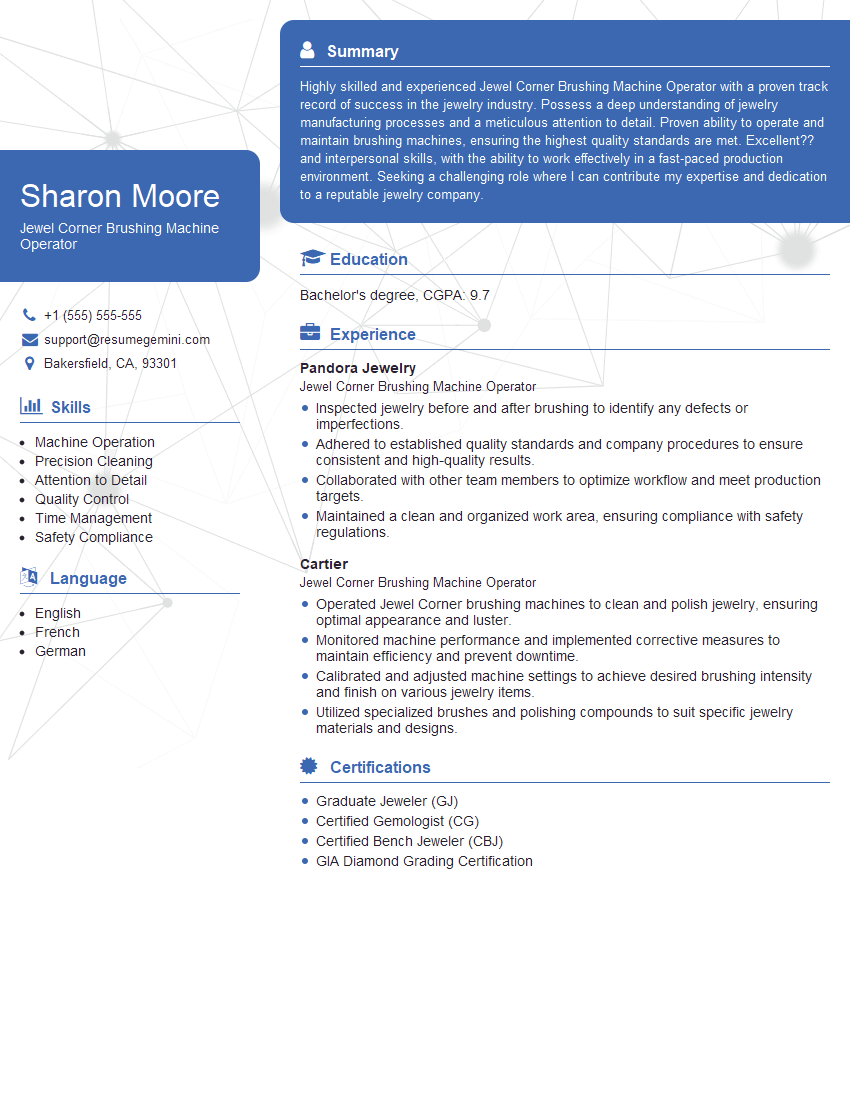

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewel Corner Brushing Machine Operator

1. Describe the process of operating a Jewel Corner Brushing Machine?

In operating a Jewel Corner Brushing Machine, I follow a systematic and detailed process to ensure efficient and precise brushing operations:

- Machine Setup and Preparation: Before commencing operations, I thoroughly inspect the machine to ensure it’s in optimal working condition. This involves checking the brush alignment, tension, and overall mechanical integrity.

- Material Positioning: I carefully position the workpiece within the designated brushing area, adhering to specified tolerances and alignment requirements.

- Brushing Parameters Adjustment: Based on the workpiece material and desired finish, I adjust the brushing parameters, such as speed, pressure, and brush type, to achieve the optimal surface texture and quality.

- Brushing Execution: With precision and control, I guide the workpiece through the brushing process, ensuring uniform coverage and consistent finishing across the entire surface.

- Quality Control: Throughout the brushing operation, I perform regular quality checks to assess the surface finish, dimensions, and adherence to specifications. Any deviations or imperfections are promptly addressed to maintain the desired product quality.

2. What are the critical maintenance procedures for a Jewel Corner Brushing Machine?

Preventive Maintenance

- Regular Cleaning: I meticulously clean the machine after each use to remove any debris, dust, or polishing compounds that may accumulate during operation.

- Brush Inspection and Replacement: I routinely inspect the brushes for wear and tear, ensuring they are in good condition to deliver consistent results. Worn-out brushes are promptly replaced to maintain optimal brushing performance.

- Lubrication: I adhere to the manufacturer’s recommended lubrication schedule, applying lubricants to designated points to minimize friction and ensure smooth machine operation.

Corrective Maintenance

- Troubleshooting: In case of any malfunctions or irregularities, I perform thorough troubleshooting to identify the root cause and implement appropriate corrective actions.

- Component Repair or Replacement: If necessary, I have the technical expertise to repair or replace faulty components, such as brushes, bearings, or electrical parts, to restore the machine to optimal working order.

3. How do you ensure the accuracy and precision of the brushing process?

- Precise Machine Setup: I meticulously calibrate and adjust the machine’s settings, including brush alignment, speed, and pressure, to ensure precise brushing operations.

- Workpiece Positioning: I utilize precision measuring tools and fixtures to accurately position the workpiece within the brushing area, minimizing any variations in surface finish.

- Quality Control Checks: Throughout the brushing process, I conduct regular quality control checks using measuring instruments, such as micrometers and surface roughness testers, to verify conformance to specifications.

- Continuous Monitoring: I remain vigilant during the brushing process, observing the workpiece’s surface and making necessary adjustments to maintain accuracy and precision.

4. How do you handle variations in workpiece materials and surface finishes?

- Material Knowledge: I possess a thorough understanding of the properties and characteristics of various workpiece materials, such as metals, plastics, and composites.

- Brush Selection: Based on the workpiece material and desired surface finish, I carefully select the appropriate brush type, considering factors like bristle material, stiffness, and density.

- Customized Parameters: I adjust the brushing parameters, such as speed, pressure, and dwell time, to optimize the brushing process for different materials and surface finishes.

- Sample Testing: Before commencing full-scale production, I conduct sample testing to determine the optimal brushing parameters and ensure the desired surface finish is achieved.

5. What safety precautions do you observe when operating a Jewel Corner Brushing Machine?

- PPE Usage: I consistently wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator, to minimize exposure to dust, debris, and other hazards.

- Machine Guarding: I ensure that all machine guards and safety devices are in place and functioning correctly to prevent contact with moving parts.

- Proper Lighting: I maintain adequate lighting in the work area to enhance visibility and reduce the risk of accidents.

- Emergency Procedures: I am familiar with emergency procedures and evacuation routes in case of any unforeseen events.

6. How do you ensure the efficiency and productivity of the brushing process?

- Optimized Machine Settings: I continually monitor and fine-tune the machine’s settings to achieve maximum efficiency and productivity.

- Workpiece Flow Management: I implement efficient workpiece handling techniques to minimize downtime and maximize throughput.

- Preventive Maintenance: By adhering to regular maintenance schedules, I minimize unexpected breakdowns and ensure the machine’s smooth operation.

- Process Improvements: I actively seek opportunities to improve the brushing process by identifying and implementing innovative techniques or modifications.

7. How do you troubleshoot common problems encountered during the brushing process?

- Surface Defects: I analyze the type and pattern of surface defects to diagnose the underlying cause, such as improper brush selection or incorrect machine settings.

- Machine Vibrations: I inspect the machine’s components, including the brush head and bearings, to identify and resolve any sources of vibration.

- Electrical Faults: I utilize electrical testing equipment to diagnose and repair electrical faults, ensuring the machine’s safe and reliable operation.

- Brush Wear: I regularly monitor brush wear and replace them promptly to maintain optimal brushing performance and prevent damage to the workpiece.

8. What is your experience with implementing quality control measures in a brushing operation?

- Inspection Techniques: I am proficient in various inspection techniques, such as visual inspection, dimensional measurement, and surface roughness testing, to assess the quality of brushed surfaces.

- Quality Standards: I have a deep understanding of industry quality standards and specifications for brushed surfaces, ensuring compliance and customer satisfaction.

- Process Monitoring: I regularly monitor the brushing process to identify any deviations from established quality standards and implement corrective actions as needed.

- Continuous Improvement: I actively participate in quality improvement initiatives, suggesting and implementing process enhancements to consistently elevate the quality of brushed products.

9. Describe your experience in working with different types of brushes used in Jewel Corner Brushing Machines.

- Natural Fiber Brushes: I have experience working with natural fiber brushes, such as Tampico and horsehair, understanding their unique properties and applications.

- Synthetic Fiber Brushes: I am familiar with various synthetic fiber brushes, including nylon, polyester, and abrasive filaments, and their suitability for different materials and finishes.

- Abrasive Brushes: I have expertise in using abrasive brushes to achieve specific surface textures and remove burrs or imperfections.

- Custom Brushes: I have experience working with custom-designed brushes to meet specific application requirements, considering factors such as brush shape, density, and bristle orientation.

10. How do you keep up with the latest advancements in Jewel Corner Brushing Machine technology?

- Industry Publications: I regularly read industry publications and attend conferences to stay informed about the latest technological developments in Jewel Corner Brushing Machines.

- Manufacturer Training: I participate in training programs offered by machine manufacturers to enhance my knowledge and skills in operating and maintaining the latest equipment.

- Online Resources: I utilize online resources, such as technical forums and webinars, to access information and connect with other professionals in the field.

- Collaboration: I actively engage with colleagues and industry experts to share knowledge and learn about innovative practices and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewel Corner Brushing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewel Corner Brushing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jewel Corner Brushing Machine Operators play a crucial role in the production process. They are responsible for operating and maintaining jewelry corner brushing machines, ensuring efficient and high-quality finishing of jewelry pieces.

1. Machine Operation

Operate jewel corner brushing machines to brush, polish, and deburr jewelry pieces.

- Load and unload jewelry pieces into the machine.

- Select and adjust machine settings based on jewelry material and desired finish.

2. Quality Control

Inspect jewelry pieces after brushing to ensure they meet quality standards.

- Check for any imperfections, scratches, or unevenness.

- Report any defects or issues to supervisors.

3. Machine Maintenance

Perform routine maintenance and cleaning of jewel corner brushing machines.

- Lubricate and adjust machine components.

- Clean and replace brushes, abrasives, and other consumables.

4. Safety Compliance

Follow all safety protocols and wear appropriate personal protective equipment.

- Operate machines safely and avoid potential hazards.

- Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some effective tips to help you impress the interviewers:

1. Research the Company and Role

Before the interview, gather information about the company, its values, and the specific requirements of the Jewel Corner Brushing Machine Operator role. This will demonstrate your interest and enthusiasm.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on current trends.

2. Practice Your Answers

Anticipate potential interview questions and prepare your responses accordingly. Consider the key job responsibilities and how your skills and experience align.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight specific examples that showcase your abilities.

3. Emphasize Relevant Experience

Tailor your responses to the specific requirements of the role. Highlight your previous experience operating jewelry brushing machines or similar equipment.

- Quantify your accomplishments with specific numbers and metrics.

- Explain how your experience has prepared you to excel in this position.

4. Ask Thoughtful Questions

Asking well-informed questions at the end of the interview shows your engagement and interest. This is an opportunity to clarify aspects of the role or company culture.

- Prepare a list of questions related to the company’s growth plans, industry trends, or training opportunities.

- Avoid asking generic or personal questions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Jewel Corner Brushing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Jewel Corner Brushing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.