Feeling lost in a sea of interview questions? Landed that dream interview for Jewelry Bench Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Jewelry Bench Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

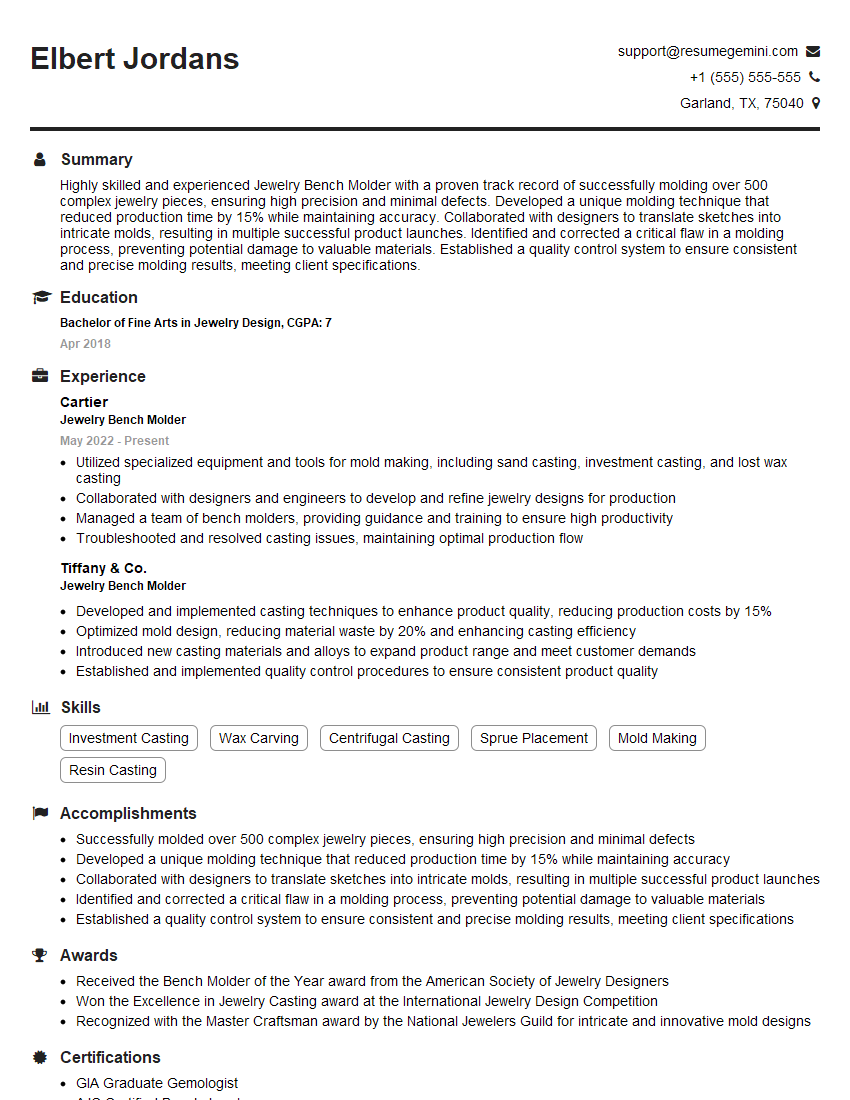

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewelry Bench Molder

1. Describe the process of creating a wax mold for jewelry.

- Carving or sculpting the original design in wax.

- Creating a sprue and attachment points to connect the wax model to the investment.

- Investing the wax model in a refractory material and heating it to burn out the wax.

- Pouring molten metal into the mold cavity and allowing it to cool and solidify.

2. What are the different types of metal casting techniques used in jewelry making?

Sandcasting

- Creating a mold using sand and a pattern.

- Pouring molten metal into the mold and allowing it to solidify.

Centrifugal Casting

- Using centrifugal force to distribute molten metal evenly in a spinning mold.

- Creating dense and strong castings with minimal porosity.

- Creating a wax model of the desired piece.

- Investing the wax model in a refractory material and burning out the wax.

- Pouring molten metal into the mold cavity and allowing it to cool and solidify.

- Using vacuum pressure to remove air and gases from the mold cavity.

- Creating castings with high accuracy and detail.

3. What are the most common alloys used in jewelry making?

- Gold (14k, 18k, 24k)

- Silver (sterling silver, fine silver)

- Platinum

- Palladium

- Copper

4. What are the factors that affect the quality of a cast jewelry piece?

- Quality of the wax model

- Proper investment and burnout

- Type of casting technique used

- Temperature of the molten metal

- Post-casting finishing and polishing

5. What are the different types of finishes that can be applied to jewelry?

- Polished finish

- Satin finish

- Brushed finish

- Antique finish

- Oxidized finish

6. What are the safety precautions that should be followed when working with molten metal?

- Wearing appropriate protective gear (heat-resistant gloves, safety glasses, etc.)

- Working in a well-ventilated area

- Never working alone

- Knowing the location of the nearest fire extinguisher

- Following all established safety protocols

7. How do you troubleshoot common problems that arise during casting?

- Porosity (caused by air bubbles or gas inclusions)

- Shrinkage (caused by the metal cooling and solidifying)

- Cracks (caused by stresses or impurities)

- Surface defects (caused by improper mold preparation or casting techniques)

8. What are the latest trends in jewelry casting technology?

- 3D printing for wax model creation

- Vacuum casting for increased accuracy and detail

- Centrifugal casting for high-production applications

- Precision casting for intricate and complex designs

- Use of eco-friendly and sustainable materials

9. What is your favorite part of the jewelry casting process?

Answer should reflect the candidate’s passion for the craft and their attention to detail.

10. What is your biggest challenge as a Jewelry Bench Molder?

Answer should demonstrate the candidate’s ability to problem-solve and overcome obstacles.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewelry Bench Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewelry Bench Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Jewelry Bench Molder, you will be instrumental in the creation of exceptional jewelry pieces, ensuring the highest levels of craftsmanship and attention to detail. Your key responsibilities will encompass a diverse range of tasks, including:

1. Model Making

Accurately recreate intricate jewelry designs from sketches, blueprints, or 3D models. Utilize traditional hand tools and specialized equipment to create wax or metal models.

2. Mold Making

Prepare and create molds using techniques such as rubber molding, investment casting, and lost-wax casting. Ensure precision and attention to detail to produce molds that accurately capture the design.

3. Casting

Handle molten metal and cast it into molds to form jewelry pieces. Control casting parameters, such as temperature and pressure, to achieve optimal results.

4. Finishing

Remove molds and finish cast pieces. Engage in tasks such as spruing, chasing, and polishing to refine the surface and enhance the overall appearance of the jewelry.

Interview Tips

To prepare for your Jewelry Bench Molder interview and maximize your chances of success, consider these tips:

1. Research the Company and Role

Thoroughly research the jewelry company and the specific role you are applying for. Understand their history, mission, key products, and the specific requirements of the position.

2. Practice Your Skills

Refresh your knowledge of mold-making techniques, casting processes, and finishing methods. Practice your hand skills and prepare examples of your past work that demonstrate your precision and creativity.

3. Showcase Your Passion

Convey your genuine passion for jewelry making and attention to detail. Highlight your understanding of the different styles and materials used in jewelry design.

4. Prepare Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the role and the company. This shows initiative and enthusiasm.

5. Dress Professionally

Dress appropriately for an interview in the jewelry industry. Consider wearing semi-formal attire or business casual clothing that reflects the professional nature of the role.

6. Be Yourself

Throughout the interview, be authentic and let your personality shine through. The interviewer wants to assess your fit for the company culture and team dynamics.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Jewelry Bench Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Jewelry Bench Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.