Feeling lost in a sea of interview questions? Landed that dream interview for Jewelry Bench Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Jewelry Bench Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

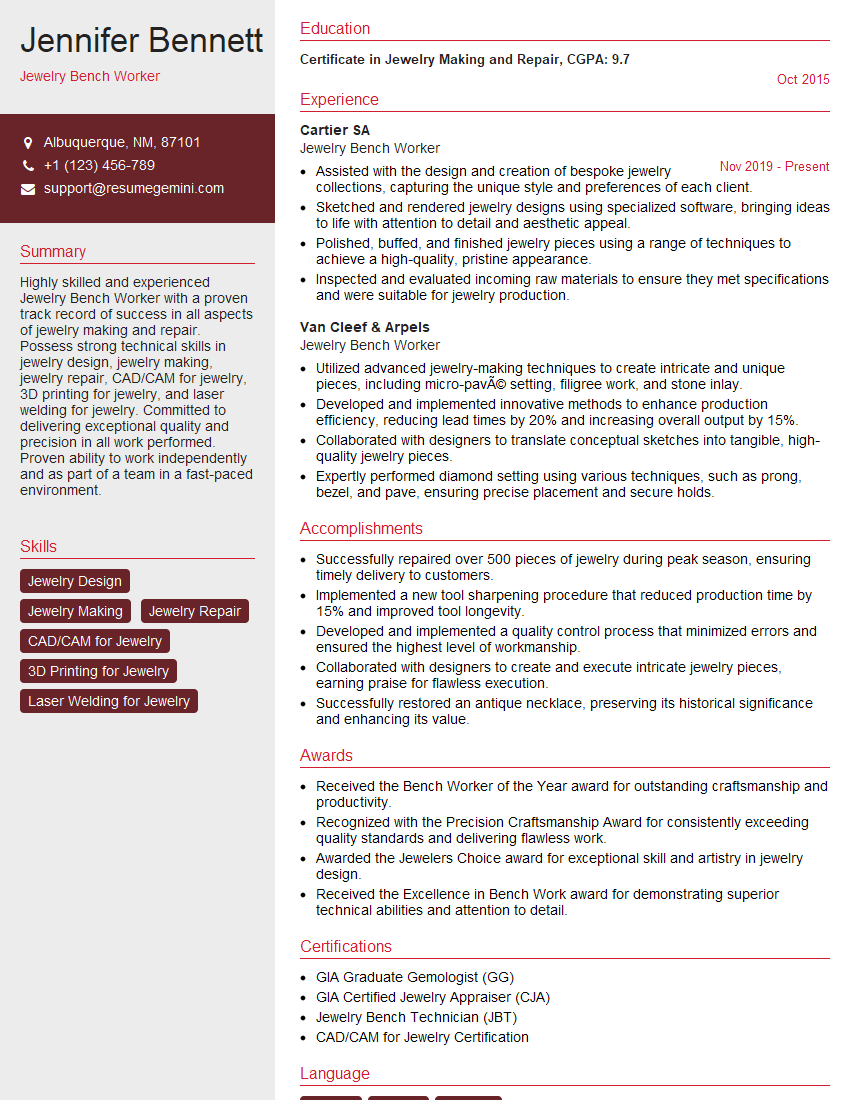

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewelry Bench Worker

1. How do you determine the purity of gold?

I use a variety of methods to determine the purity of gold, including:

- Acid testing: This involves applying a drop of nitric acid to the gold and observing the reaction. Pure gold will not react with nitric acid, while lower-purity gold will produce a green or black reaction.

- X-ray fluorescence (XRF): This is a non-destructive method that uses X-rays to determine the elemental composition of the gold. XRF can provide accurate measurements of the gold’s purity and identify any other metals present.

2. What are the different types of gem settings?

Prong setting

- Consists of small metal claws or prongs that hold the gemstone in place.

- Secure and allows light to pass through the gemstone.

Bezel setting

- Involves a metal rim that surrounds the gemstone.

- Provides protection and can enhance the gemstone’s color.

3. How do you repair a broken gemstone?

The method of repairing a broken gemstone depends on the type of gemstone and the nature of the break. Some common repair techniques include:

- Adhesive bonding: Using a specialized adhesive to bond the broken pieces together.

- Laser welding: Using a laser to melt and fuse the broken pieces together.

- Repolishing: Smoothing and polishing the repaired area to restore its original appearance.

4. What are the different types of soldering techniques used in jewelry making?

There are several soldering techniques commonly used in jewelry making, including:

- Hard soldering: Using a high-temperature solder to create a strong, permanent bond between metal parts.

- Soft soldering: Using a lower-temperature solder to create a more flexible bond that can be used for delicate pieces.

- Laser soldering: Using a laser to melt and fuse metal parts together, providing precise control and minimal heat distortion.

5. How do you polish gold to achieve a high shine?

To polish gold to achieve a high shine, I use a combination of techniques:

- Mechanical polishing: Using abrasive materials such as sandpaper or polishing wheels to remove imperfections and smooth the surface.

- Chemical polishing: Using a chemical solution to dissolve and remove surface impurities.

- Electrolytic polishing: Using an electric current to remove metal ions from the surface, resulting in a smooth and shiny finish.

6. What are the safety precautions you observe while working with precious metals and gemstones?

I adhere to strict safety precautions to protect myself and others while working with precious metals and gemstones:

- Proper ventilation: Ensure adequate ventilation to avoid inhaling fumes or dust.

- Protective gear: Wear gloves, safety glasses, and a respirator when handling toxic materials or using power tools.

- Proper storage: Store precious metals and gemstones securely to prevent theft or damage.

7. What are the different techniques used for engraving jewelry?

There are several techniques used for engraving jewelry, each resulting in a unique look:

- Hand engraving: Using a sharp tool to manually create designs and inscriptions.

- Laser engraving: Using a laser to etch designs and patterns onto the metal surface.

- CNC engraving: Using a computer-controlled machine to precisely engrave intricate designs.

8. How do you determine the appropriate solder for different types of jewelry?

Choosing the right solder depends on the type of metal being used and the desired strength and color of the joint. I consider factors such as:

- Metal composition: Different metals require different solder alloys to ensure a strong and compatible bond.

- Melting point: The solder’s melting point should be below the melting point of the metal being used.

- Color: The solder should match the color of the metal to create a seamless appearance.

9. What techniques do you use to create intricate details on jewelry pieces?

Creating intricate details requires a combination of skills and techniques, including:

- Wax carving: Using wax to sculpt the desired design, which is then cast into metal.

- Hand engraving: Using sharp tools to manually carve designs into the metal surface.

- Stone setting: Setting gemstones into the jewelry piece using various techniques such as prong setting or bezel setting.

10. How do you ensure the quality of jewelry before it leaves the workshop?

I implement a thorough quality control process to ensure the highest standards:

- Visual inspection: Meticulously examining the piece for any imperfections or defects.

- Weight and measurement verification: Verifying that the piece meets the specified weight and dimensions.

- Stone setting inspection: Ensuring that gemstones are securely set and free from damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewelry Bench Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewelry Bench Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jewelry Bench Workers are responsible for a variety of tasks related to the creation and repair of jewelry. Their duties may include:

1. Crafting and Repairing Jewelry

Bench workers use their skills and knowledge of jewelry making to create new pieces of jewelry or repair existing pieces. They may work with a variety of materials, including gold, silver, platinum, and gemstones.

- Creating new pieces of jewelry from scratch, using a variety of techniques such as soldering, casting, and stone setting.

- Repairing damaged jewelry, such as fixing broken clasps, replacing lost stones, and resizing rings.

2. Using and Maintaining Tools and Equipment

Bench workers use a variety of tools and equipment to create and repair jewelry. They must be able to use these tools safely and efficiently.

- Using hand tools to shape and manipulate metal, such as pliers, hammers, and files.

- Operating power tools to cut, drill, and polish metal, such as saws, drills, and grinders.

- Maintaining and calibrating tools and equipment to ensure accuracy and safety.

3. Inspecting and Assessing Jewelry

Bench workers must be able to inspect and assess jewelry to determine its condition and identify any potential problems. They must also be able to communicate their findings to customers and other members of the team.

- Examining jewelry to identify any damage or defects.

- Assessing the value of jewelry, based on its materials, craftsmanship, and condition.

- Communicating findings to customers and other members of the team.

4. Providing Customer Service

Bench workers often interact with customers, either in person or over the phone. They must be able to provide excellent customer service, including answering questions, providing advice, and resolving any issues.

- Greeting customers and assisting them with their inquiries.

- Answering questions about jewelry, its materials, and its value.

- Providing advice on jewelry care and maintenance.

- Resolving any issues or complaints that customers may have.

Interview Tips

To ace an interview for a Jewelry Bench Worker position, it is important to be prepared and to highlight your skills and experience. Here are some tips to help you prepare for your interview:

1. Research the Company and the Position

Learn about the company’s history, culture, and products. This will help you to understand the company’s needs and to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about its history, mission, and products.

- Read online reviews of the company to get an idea of its culture and work environment.

2. Prepare to Talk About Your Skills and Experience

Highlight your skills and experience in jewelry making and repair. Be sure to emphasize your proficiency in using the tools and equipment of the trade.

- Make a list of your skills and experience, including your experience with different jewelry making and repair techniques.

- Prepare examples of your work to show the interviewer.

3. Practice Your Answers to Common Interview Questions

Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Write out your answers to common interview questions.

- Practice your answers aloud until you feel confident in your delivery.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position.

- Wear clean, pressed clothing that is appropriate for a business setting.

- Arrive at the interview location 10-15 minutes early.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jewelry Bench Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.