Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Jewelry Drill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

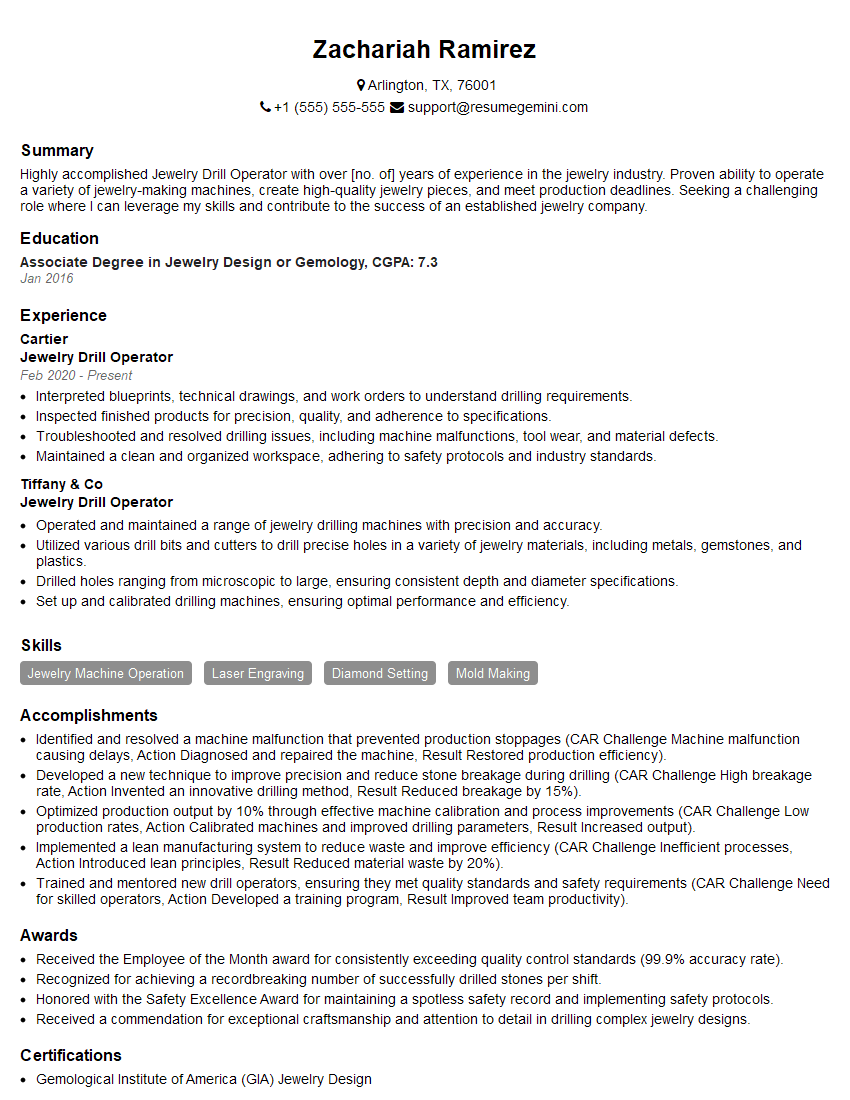

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewelry Drill Operator

1. Describe the process of drilling holes in jewelry using a drill press.

As a Jewelry Drill Operator, I follow a structured process to drill holes in jewelry:

- Setup: I secure the jewelry piece in a jig or vise, ensuring it’s stable and properly aligned with the drill bit.

- Drill Bit Selection: I select the appropriate drill bit based on the hole size, material, and desired finish.

- Drilling: I calibrate the drill press to the correct speed and depth, and carefully drill the hole, maintaining steady pressure and minimizing vibration.

- Deburring: After drilling, I remove any burrs or imperfections around the hole using hand tools or a deburring machine.

- Quality Control: I inspect the drilled hole to ensure it meets specifications, including hole size, location, and surface finish.

2. What are the different types of drill bits used in jewelry drilling?

Materials

- High-Speed Steel (HSS): Suitable for general-purpose drilling in softer metals, such as gold, silver, and copper.

- Cobalt Steel: Stronger than HSS, used for drilling harder metals, such as stainless steel and titanium.

- Carbide: Extremely hard and wear-resistant, used for precision drilling of hard materials, such as gemstones.

Shapes

- Twist Drill: Standard drill bit for creating cylindrical holes.

- Step Drill: Creates holes of varying diameters in a single pass.

- Pilot Drill: Used to create a small pilot hole before drilling a larger hole.

3. How do you ensure the accuracy and precision of drilled holes?

- Proper Jig or Vise: I use specialized jigs or vises to hold the jewelry securely, ensuring accurate alignment and minimizing movement.

- Sharp Drill Bits: I consistently sharpen drill bits to maintain their cutting edge, reducing the risk of deviation or breakage.

- Stabilization: I stabilize the drill press and minimize vibrations by using a heavy base and vibration-dampening techniques.

- Practice and Experience: Regular practice and experience allow me to develop the precision and dexterity necessary for accurate drilling.

4. Describe the types of machines and equipment used in jewelry drilling.

- Drill Press: Bench-mounted or floor-standing machine that provides rotational power and precise control over drilling depth and speed.

- Jigs and Vises: Devices that secure and align jewelry pieces for precise drilling.

- Sharpening Equipment: Grinding wheels or stones used to sharpen drill bits, ensuring optimal cutting performance.

- Cleaning Tools: Ultrasonic cleaners or brushes used to remove debris and ensure proper lubrication.

- Magnification Tools: Loupes or microscopes used to enhance visibility and precision during drilling.

5. How do you handle and store a variety of drill bits?

- Proper Storage: I store drill bits in organized containers or racks to prevent damage and maintain sharpness.

- Cleaning and Lubrication: I regularly clean drill bits to remove debris and lubricate them to extend their lifespan.

- Size and Type Organization: I label and organize drill bits based on size and type for easy identification and selection.

- Handling with Care: I handle drill bits with care to minimize damage to the cutting edges.

6. What are common challenges faced in jewelry drilling, and how do you overcome them?

Challenges

- Delicate Materials: Drilling into delicate materials requires great care and precision.

- Small Hole Sizes: Drilling very small holes requires specialized equipment and techniques.

- Precision Alignment: Maintaining accurate alignment is crucial for precise drilling.

Solutions

- Patience and Skill: I approach delicate materials with patience and utilize the proper techniques to avoid damage.

- Specialized Equipment: I use high-quality precision drills and micro-drilling attachments for small holes.

- Magnification and Jigs: I utilize magnification tools and jigs to ensure proper alignment and accuracy.

7. Describe the safety precautions you follow when operating a drill press.

- Personal Protective Equipment (PPE): I wear appropriate PPE, including safety glasses, gloves, and earplugs.

- Machine Inspection: I inspect the drill press before use for any damage or loose parts.

- Secure Workpiece: I ensure the jewelry piece is securely fastened to prevent it from moving or flying off during drilling.

- Clear Work Area: I maintain a clean and clutter-free work area to minimize distractions and hazards.

- Emergency Stop Awareness: I familiarize myself with the drill press’s emergency stop button and its location.

8. What types of materials have you drilled for jewelry making?

- Metals: Gold, silver, platinum, stainless steel

- Gemstones: Diamonds, sapphires, rubies, emeralds

- Organic Materials: Wood, bone, shell

- Other: Glass, ceramic, polymer clay

9. What is the most complex or intricate drilling project you have worked on?

In a recent project, I was tasked with drilling a series of small and precise holes in a delicate gold pendant. The holes had to be evenly spaced and aligned perfectly for the attachment of intricate filigree work. I utilized a high magnification microscope and a specialized micro-drilling attachment to achieve the required accuracy. The successful completion of this project demonstrated my ability to handle challenging tasks with precision and attention to detail.

10. How do you stay updated with the latest techniques and advancements in jewelry drilling?

- Trade Shows and Conferences: I attend industry events to learn about new equipment and techniques.

- Online Resources: I subscribe to industry publications and forums to stay informed about best practices and innovations.

- Training and Workshops: I participate in training opportunities to enhance my skills and knowledge.

- Collaboration with Peers: I exchange knowledge and ideas with other jewelry drill operators to stay updated on the latest trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewelry Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewelry Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jewelry Drill Operator plays a crucial role in the jewelry making process by meticulously operating drilling machines to create precise holes in various types of precious metals, such as gold, silver, and platinum. Their primary responsibilities include:

1. Accurate Drilling Operations

Jewelry Drill Operators must possess exceptional dexterity and precision in operating drilling machines to create clean, accurate holes with varying diameters and depths. They must adhere to specific design specifications and ensure that the holes are aligned perfectly to achieve the desired design outcome.

- Select the appropriate drill bits and settings based on the material, design, and hole specifications.

- Position the workpiece securely and operate the drilling machine with precision to create holes with precise diameters, depths, and angles.

2. Material Handling and Inspection

Jewelry Drill Operators are responsible for handling precious metals and gemstones with utmost care during the drilling process. They must inspect the materials for defects, blemishes, or imperfections prior to drilling to minimize the risk of damage or wastage.

- Identify and select suitable materials for drilling based on design requirements and material properties.

- Carefully inspect materials for any defects or irregularities before drilling to ensure product quality.

3. Machine Maintenance and Calibration

To ensure optimal performance and accuracy, Jewelry Drill Operators are responsible for maintaining and calibrating the drilling machines they use. Regular maintenance tasks include cleaning, lubrication, and adjustments to maintain precision and prevent malfunctions.

- Perform routine maintenance tasks on drilling machines, including cleaning, lubrication, and minor adjustments.

- Calibrate drilling machines regularly to ensure accurate hole dimensions and prevent deviations.

4. Quality Assurance and Control

Jewelry Drill Operators are accountable for ensuring the quality of their work by conducting thorough inspections and adhering to established quality standards. They must identify and correct any deviations or errors to maintain the integrity and value of the jewelry pieces.

- Inspect drilled holes for accuracy, dimensions, and surface finish to meet quality specifications.

- Identify and rectify any defects or errors in the drilling process to maintain product quality.

Interview Tips

To ace the interview for a Jewelry Drill Operator position, it is crucial to prepare thoroughly and demonstrate your skills, experience, and knowledge. Here are some valuable interview tips to help you make a strong impression:

1. Research the Company and Position

Before the interview, take the time to research the jewelry company and the specific role you are applying for. Understanding the company’s values, products, and industry reputation will enable you to tailor your answers to the interviewer’s questions and show that you are genuinely interested in the opportunity.

- Visit the company website to learn about their history, products, and commitment to quality.

- Read industry publications and news articles to stay informed about current trends and developments in the jewelry industry.

2. Highlight Your Skills and Experience

During the interview, confidently present your relevant skills and experience that align with the job requirements. Emphasize your proficiency in operating drilling machines, handling precious metals, and maintaining equipment. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Describe your experience in operating different types of drilling machines and the materials you have worked with.

- Provide specific examples of how you have ensured accuracy and precision in your drilling operations.

3. Demonstrate Attention to Detail and Quality

Jewelry Drill Operators play a critical role in maintaining the quality of jewelry pieces. In the interview, highlight your meticulous nature and unwavering attention to detail. Explain how you carefully inspect materials, identify defects, and take corrective actions to ensure the highest possible quality.

- Share examples of how you have identified and corrected errors in the drilling process, preventing defects.

- Describe your commitment to maintaining a clean and organized work area to prevent contamination or damage to materials.

4. Be Prepared to Answer Technical Questions

Interviewers may ask technical questions to assess your proficiency in operating drilling machines and understanding of the drilling process. Be prepared to discuss different types of drill bits, speeds, and techniques. Demonstrate your knowledge of material properties and how they affect drilling operations.

- Explain the factors that influence the selection of drill bits and drilling parameters.

- Describe your experience in troubleshooting and resolving common drilling problems.

Next Step:

Now that you’re armed with the knowledge of Jewelry Drill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Jewelry Drill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini