Are you gearing up for an interview for a Jewelry Drilling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jewelry Drilling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

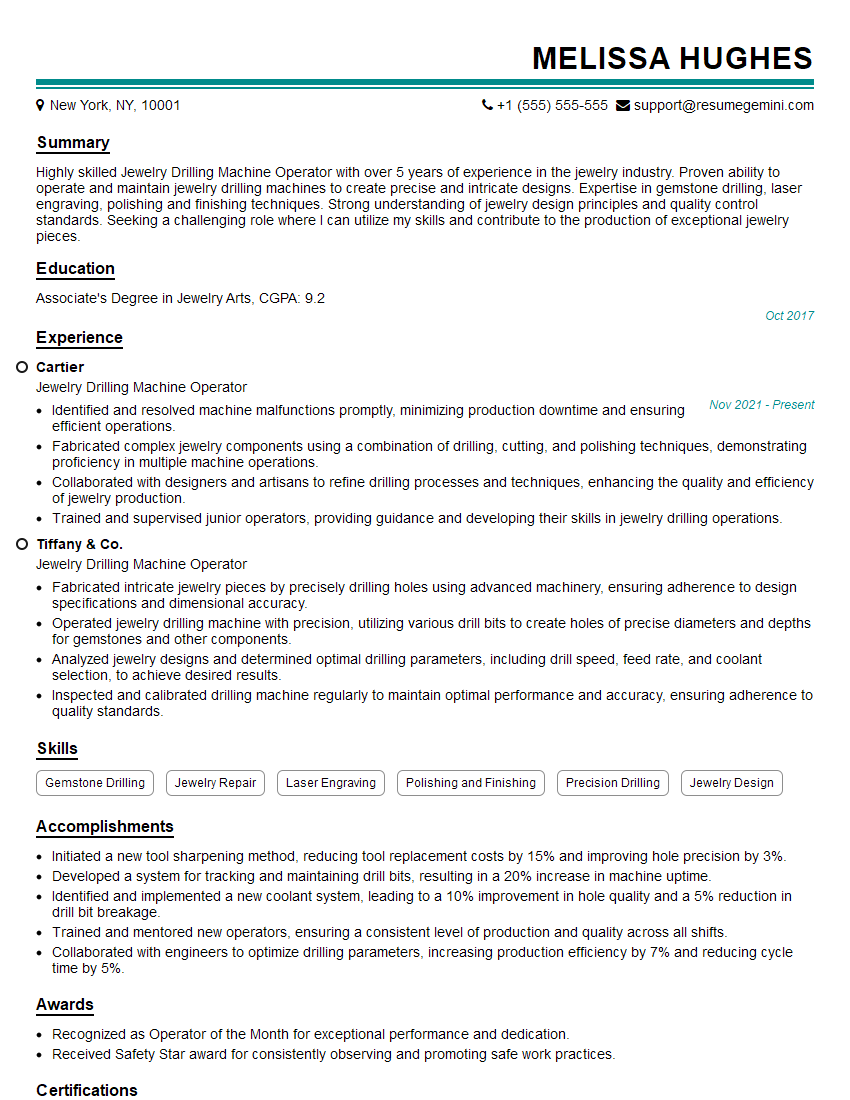

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewelry Drilling Machine Operator

1. What are the different types of drilling machines used in jewelry making?

There are several types of drilling machines used in jewelry making, including:

- Benchtop drilling machines: These are small, portable machines that are ideal for small-scale operations. They typically have a drill press and a table that can be adjusted to accommodate different sizes of jewelry.

- Floor-standing drilling machines: These are larger, more powerful machines that are used for heavier-duty work. They typically have a larger drill press and a sturdier table, and they can be used to drill larger holes in thicker materials.

- CNC drilling machines: These are computer-controlled machines that are used for precision drilling. They can be programmed to drill holes with specific depths, diameters, and locations, and they can produce highly accurate results.

2. What are the safety precautions that should be taken when operating a jewelry drilling machine?

Safe Work Practices

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and well-lit.

- Inspect the machine before each use to ensure that it is in good working condition.

- Never operate the machine if you are tired or under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for the safe operation of the machine.

Machine Safety Features

- Use a drill press with a safety shield to prevent flying chips from hitting you.

- Use a drill bit that is the correct size for the hole you are drilling.

- Clamp the workpiece securely in place before drilling.

- Never reach around or over the drill bit while it is rotating.

- Turn off the machine and unplug it before making any adjustments.

3. How do you choose the right drill bit for a particular job?

The right drill bit for a particular job depends on several factors, including:

- The material being drilled: Different materials require different types of drill bits. For example, carbide drill bits are best for drilling hard materials like metal, while masonry drill bits are best for drilling concrete.

- The size of the hole: The diameter of the drill bit should be slightly larger than the diameter of the hole you want to drill.

- The shape of the hole: Some drill bits are designed to drill round holes, while others are designed to drill square or triangular holes.

4. How do you sharpen a drill bit?

There are several ways to sharpen a drill bit, including:

- Using a drill bit sharpener: This is a specialized tool that can quickly and easily sharpen drill bits.

- Using a grinding wheel: This is a more manual method of sharpening drill bits, but it can be just as effective as using a drill bit sharpener.

- Using a sharpening stone: This is the most basic method of sharpening drill bits, but it can be time-consuming and requires some skill.

5. How do you troubleshoot a jewelry drilling machine?

There are several things to check if your jewelry drilling machine is not working properly, including:

- The power supply: Make sure that the machine is plugged in and that the power switch is turned on.

- The chuck: Make sure that the chuck is tight and that the drill bit is securely inserted.

- The belts: Make sure that the belts are tight and that they are not damaged.

- The bearings: Make sure that the bearings are lubricated and that they are not worn out.

6. What are the different types of drill presses that can be used for jewelry making?

There are several different types of drill presses that can be used for jewelry making, including:

- Benchtop drill presses: These are small, portable drill presses that are ideal for small-scale jewelry making operations.

- Floor-standing drill presses: These are larger, more powerful drill presses that are used for heavier-duty work.

- CNC drill presses: These are computer-controlled drill presses that are used for precision drilling.

7. What are the different types of drill bits that can be used for jewelry making?

There are several different types of drill bits that can be used for jewelry making, including:

- Twist drill bits: These are the most common type of drill bit, and they can be used to drill holes in a variety of materials.

- Carbide drill bits: These are made from a hard material called carbide, and they are used for drilling holes in hard materials like metal.

- Masonry drill bits: These are made from a hard material called masonry, and they are used for drilling holes in concrete and other hard materials.

8. What are the different types of attachments that can be used with a jewelry drilling machine?

There are several different types of attachments that can be used with a jewelry drilling machine, including:

- Drill bits: These are the most common type of attachment, and they are used to drill holes in a variety of materials.

- Countersinks: These are used to create countersunk holes, which are holes that have a wider diameter at the top than at the bottom.

- Reamer: These are used to enlarge holes that have already been drilled.

- Taps: These are used to create threads in holes.

9. What are the different safety precautions that should be taken when using a jewelry drilling machine?

There are several different safety precautions that should be taken when using a jewelry drilling machine, including:

- Always wear safety glasses: This will protect your eyes from flying debris.

- Wear gloves: This will protect your hands from sharp edges.

- Secure the workpiece: This will prevent the workpiece from moving and causing injury.

- Use the correct speed and feed rate: This will help to prevent the drill bit from breaking.

- Do not overload the machine: This could cause the machine to overheat and fail.

10. How do you maintain a jewelry drilling machine?

Regular maintenance is essential to keep a jewelry drilling machine in good working condition. Some of the maintenance tasks that should be performed include:

- Cleaning the machine: This should be done on a regular basis to remove any dirt or debris that may have accumulated.

- Oiling the machine: This should be done according to the manufacturer’s instructions.

- Inspecting the machine: This should be done on a regular basis to identify any potential problems.

- Sharpening the drill bits: This should be done as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewelry Drilling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewelry Drilling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jewelry Drilling Machine Operator is accountable for operating and maintaining drilling machines used to create precise holes in jewelry pieces. Their responsibilities encompass:

1. Machine Operation

Adhering to established protocols and specifications, the operator sets up, calibrates, and operates drilling machines.

- Positioning and securing jewelry items within the machine’s work area.

- Choosing and installing appropriate drill bits and attachments.

- Adjusting drilling parameters such as speed, depth, and pressure.

- Monitoring the drilling process to ensure accuracy and precision.

2. Quality Control

Meticulously inspecting drilled pieces to verify adherence to quality standards.

- Evaluating hole dimensions, placement, and surface finish.

- Identifying and correcting any defects or deviations.

3. Machine Maintenance

Performing regular maintenance and troubleshooting to ensure optimal machine performance.

- Cleaning and lubricating machine components.

- Replacing worn or damaged parts.

- Reporting any operational issues or malfunctions.

4. Material Handling

Safely handling delicate jewelry pieces and materials.

- Properly storing and retrieving jewelry items.

- Using appropriate tools and techniques to prevent damage during handling.

Interview Tips

To excel in a Jewelry Drilling Machine Operator interview, consider these preparation tips:

1. Research the Company and Role

Demonstrate your enthusiasm and interest by thoroughly researching the company, its products, and the specific role you’re applying for.

- Visit the company website and LinkedIn page.

- Read industry news and articles related to jewelry manufacturing.

- Familiarize yourself with the job description and identify key skills and responsibilities.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating drilling machines, particularly in the jewelry industry. Quantify your accomplishments and provide specific examples whenever possible.

- Describe your proficiency in setting up and calibrating drilling equipment.

- Mention your ability to maintain tight tolerances and achieve high levels of accuracy.

- Showcase your attention to detail and commitment to quality.

3. Prepare for Technical Questions

Expect technical questions related to drilling machine operation, maintenance, and troubleshooting. Review common drilling techniques, safety protocols, and industry standards.

- Practice answering questions about drill bit selection, speed adjustment, and hole inspection.

- Be prepared to discuss your experience in identifying and resolving machine malfunctions.

4. Show Enthusiasm and Passion

Convey your passion for jewelry making and your commitment to precision and craftsmanship. Employers seek individuals who are enthusiastic about their work and take pride in their creations.

- Explain why you are drawn to the jewelry industry and what motivates you in this field.

- Share examples of your attention to detail and dedication to quality in your previous roles.

5. Practice Your Answers

Prepare responses to common interview questions and practice delivering them confidently and effectively.

- rehearse your answers to questions about your strengths, weaknesses, and career goals.

- Consider potential questions about your experience with specific drilling techniques or equipment.

6. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing appropriately and arriving on time for your interview. This demonstrates your respect for the interviewer and the company.

- Wear clean, business-casual attire.

- Plan your route in advance to avoid any unexpected delays.

7. Ask Thoughtful Questions

Asking well-informed questions at the end of the interview shows your interest in the company and the role. Prepare a few thoughtful questions that demonstrate your curiosity and engagement.

- Inquire about the company’s commitment to quality and customer satisfaction.

- Ask about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jewelry Drilling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!