Are you gearing up for an interview for a Jewelry Enameler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jewelry Enameler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

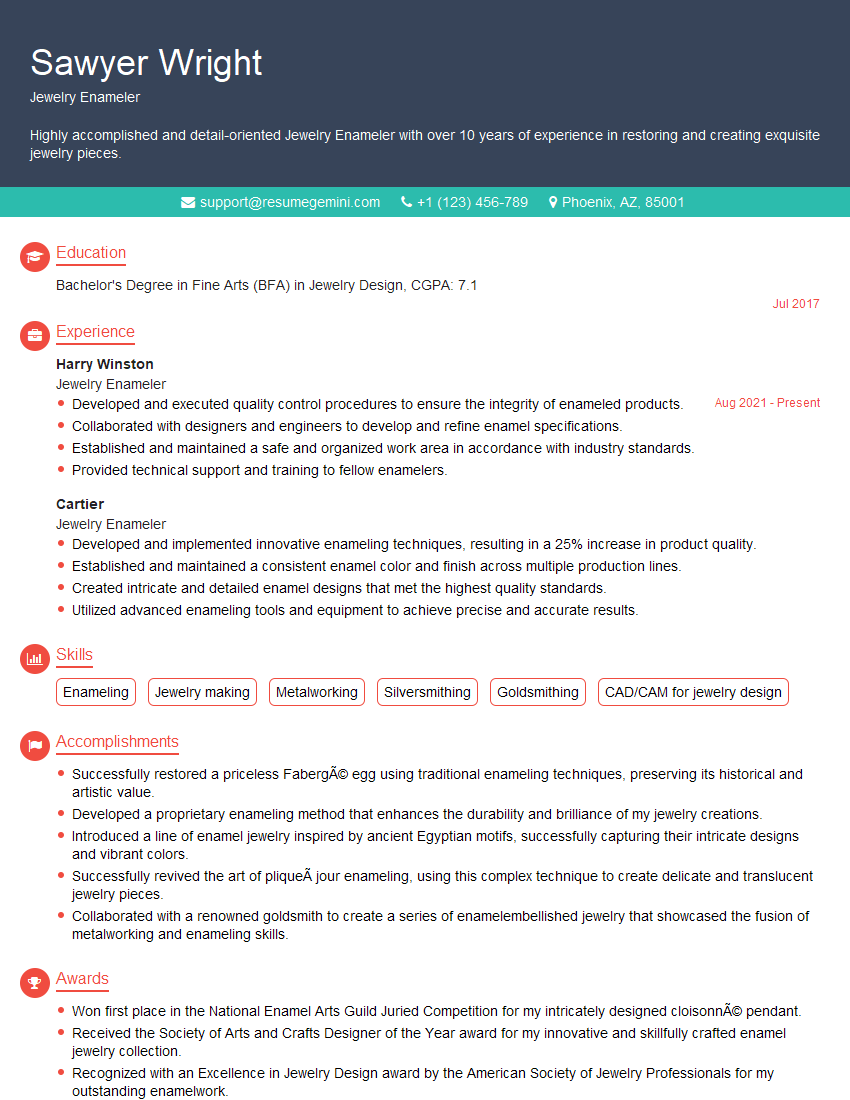

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jewelry Enameler

1. What is the process of cloisonné enameling?

Cloisonné enameling is a technique in which metal wires are used to create compartments on a metal surface. These compartments are then filled with enamel powder and fired in a kiln.

- The process begins by creating a design on the metal surface.

- Metal wires are then bent and shaped to follow the design.

- The wires are soldered to the metal surface, creating the compartments.

- Enamel powder is then applied to the compartments.

- The piece is then fired in a kiln, melting the enamel powder and fusing it to the metal.

2. What are the different types of enamels?

- Transparent enamels allow light to pass through them, revealing the metal surface beneath.

- Opaque enamels do not allow light to pass through them, creating a solid color.

- Opalescent enamels have a milky, translucent appearance.

- Iridescent enamels have a rainbow-like sheen.

- Vitreous enamels are hard and durable, making them suitable for use on jewelry and other decorative objects.

3. What are the different techniques used to apply enamel?

- Dry enameling involves applying dry enamel powder to the metal surface.

- Wet enameling involves applying enamel powder that has been mixed with water or oil.

- Slurry enameling involves applying enamel powder that has been mixed with a liquid binder.

- Sifting enameling involves sprinkling enamel powder onto the metal surface.

- Spray enameling involves spraying enamel powder onto the metal surface.

4. What are the different types of kilns used for enameling?

- Electric kilns are the most common type of kiln used for enameling.

- Gas kilns are also used for enameling, but they require more specialized equipment.

- Raku kilns are used to create a unique crackled effect on enameled pieces.

- Microwave kilns are a relatively new type of kiln that can be used for enameling.

5. What are the different factors that affect the firing of enamel?

- The temperature of the kiln

- The length of time the piece is fired

- The type of enamel used

- The thickness of the enamel layer

- The presence of any other metals or materials on the piece

6. What are the different types of defects that can occur in enameled pieces?

- Blisters are caused by air bubbles that become trapped in the enamel during firing.

- Crazing is a network of fine cracks that can appear in the enamel after firing.

- Fisheyes are small, circular areas of enamel that have a different color or texture than the rest of the piece.

- Pinholing is a series of small holes that can appear in the enamel after firing.

- Warping is a distortion of the metal surface that can occur during firing.

7. How can you prevent defects from occurring in enameled pieces?

- Use clean metal surfaces.

- Apply the enamel evenly and thinly.

- Fire the piece at the correct temperature and for the correct length of time.

- Cool the piece slowly after firing.

- Inspect the piece carefully for any defects before it is finished.

8. What are the different types of tools used in enameling?

- Pliers

- Cutters

- Tweezers

- Brushes

- Spatulas

- Kilns

- Safety equipment

9. What are the different types of safety precautions that should be taken when enameling?

- Wear gloves and eye protection when working with enamels.

- Use a well-ventilated area when working with enamels.

- Do not eat or drink in the area where you are working with enamels.

- Keep enamels out of reach of children and pets.

- Dispose of enamels properly.

10. What are the different types of careers that are available for jewelry enamelers?

- Jewelry designers

- Jewelry makers

- Enameling instructors

- Enameling consultants

- Enameling studio owners

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jewelry Enameler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jewelry Enameler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jewelry Enamelers are highly skilled artisans who apply protective or decorative coatings to metal objects, primarily jewelry. Their meticulous work enhances the aesthetic appeal and durability of the jewelry.

1. Preparing Metal Surfaces

Jewelry Enamelers begin by meticulously preparing the metal surface. They clean, degrease, and apply a base coat to ensure proper adhesion of the enamel.

- Clean metal surfaces using solvents, detergents, and abrasives.

- Apply base coats or primers to prepare the surface for enamel application.

2. Applying Enamel

The core responsibility of Jewelry Enamelers involves applying enamel to prepared metal surfaces. They use various techniques, including:

- Wet packing: Applying wet enamel powder mixed with water or oil to the metal surface.

- Dry packing: Applying dry enamel powder to the metal surface.

- Sieving: Sprinkling enamel powder through a sieve to create a uniform layer.

3. Firing Enamel

Once the enamel is applied, Jewelry Enamelers subject it to controlled heating in a kiln. Firing melts the enamel, fusing it to the metal surface.

- Operate kilns and monitor temperatures to fire enamel effectively.

- Adjust firing parameters based on the type of enamel and metal substrate.

4. Finishing Techniques

After firing, Jewelry Enamelers employ various finishing techniques to enhance the appearance and durability of the jewelry.

- Polishing or grinding to smooth and refine the enamel surface.

- Applying transparent glazes or protective coatings to enhance durability.

- Inlaying or setting gemstones or other decorative elements to embellish the design.

Interview Tips

To ace an interview for a Jewelry Enameler position, consider these tips:

1. Research the Company and Position

Thoroughly research the company, its values, and the specific requirements of the Jewelry Enameler role. This knowledge will enable you to tailor your answers and demonstrate your understanding of the company’s needs.

- Visit the company’s website and social media profiles.

- Read industry publications and online forums to gain insights into the latest trends and techniques in jewelry enameling.

2. Showcase Your Portfolio and Skills

Bring a portfolio of your best work to the interview. Include examples that demonstrate your technical proficiency, artistic ability, and attention to detail. Be prepared to discuss your techniques and the inspiration behind your designs.

- Prepare a digital portfolio or physical samples that highlight your range of skills.

- Discuss your creative process, including how you translate ideas into tangible pieces of jewelry.

3. Emphasize Your Attention to Detail

Jewelry enameling requires meticulous attention to detail and precision. Emphasize your ability to work with small and intricate designs and your dedication to producing high-quality results.

- Provide examples of projects where you achieved precise and accurate results.

- Explain your quality control processes and how you ensure customer satisfaction.

4. Prepare for Technical Questions

Interviewers may ask technical questions to assess your understanding of enameling techniques and materials. Be confident in explaining the different types of enamel, firing processes, and safety precautions.

- Research different types of enamel, their properties, and applications.

- Practice describing the steps involved in firing enamel and the factors that affect the final outcome.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jewelry Enameler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!