Are you gearing up for an interview for a Jig and Fixture Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jig and Fixture Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

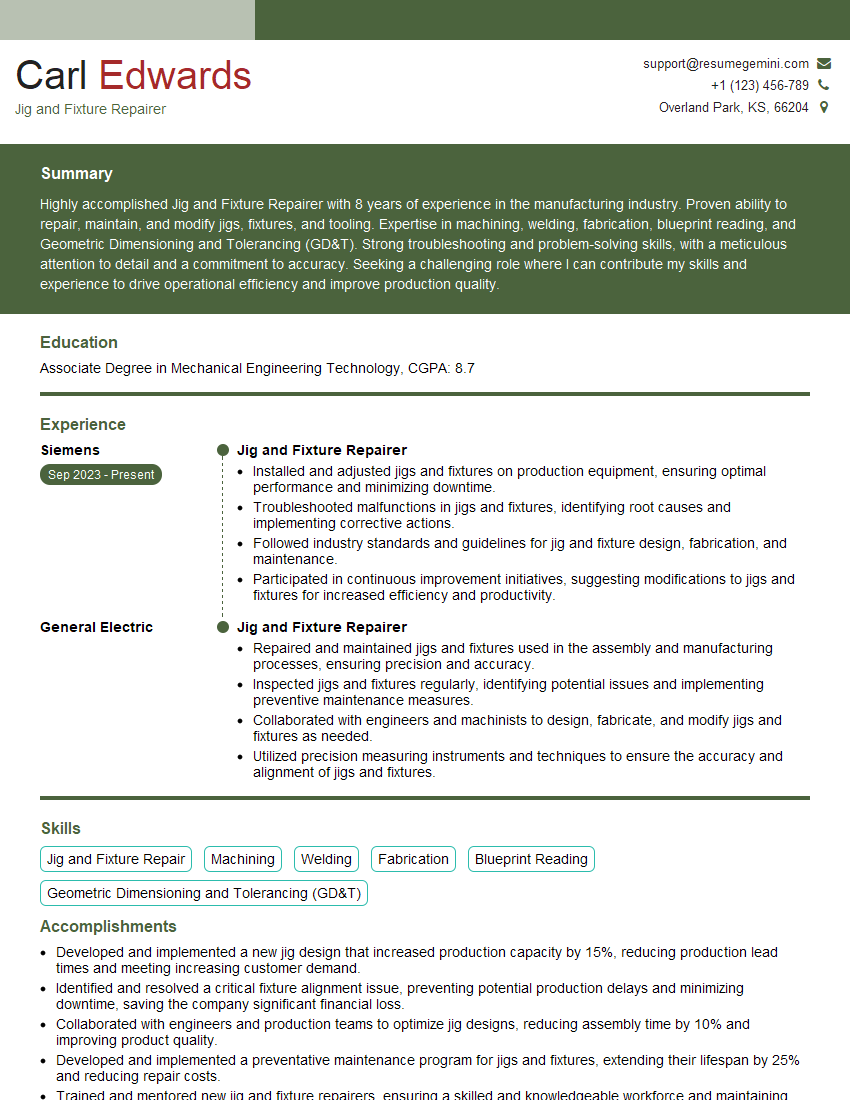

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig and Fixture Repairer

1. Explain the purpose of using jigs and fixtures in manufacturing?

Jigs and fixtures are essential tools in manufacturing as they provide accuracy, repeatability, and safety in the production process. Jigs are used to guide cutting tools and hold workpieces in place during machining operations, ensuring precision and minimizing errors. Fixtures, on the other hand, are used to hold and position workpieces for assembly, inspection, or testing, providing stability and facilitating efficient operations.

2. Describe the different types of jigs and fixtures used in manufacturing and their applications?

Jigs

- Drill jigs: Used to guide drills for precise hole placement.

- Milling jigs: Used to guide milling cutters for complex machining operations.

- Boring jigs: Used to guide boring tools for accurate hole enlargement.

Fixtures

- Assembly fixtures: Used to hold parts in place during assembly.

- Inspection fixtures: Used to position parts for dimensional and quality inspection.

- Welding fixtures: Used to hold parts securely during welding operations.

3. What are the key considerations when designing and fabricating jigs and fixtures?

- Accuracy and precision: Jigs and fixtures must ensure high levels of accuracy and precision in the machining or assembly process.

- Durability and wear resistance: They should be made of durable materials that can withstand repeated use and wear.

- Ease of use and safety: Jigs and fixtures should be designed for ease of operation and minimize risks to operators.

- Interchangeability: They should be designed to allow for interchangeability of parts and components.

4. What are the common materials used in jig and fixture fabrication and why?

- Steel: Durable, wear-resistant, and suitable for heavy-duty applications.

- Aluminum: Lightweight, corrosion-resistant, and ideal for jigs and fixtures in aerospace and electronics.

- Cast iron: Provides excellent vibration damping and is used in heavy machinery.

- Plastic: Lightweight, easy to machine, and suitable for low-volume or prototype applications.

5. Describe the process of repairing and maintaining jigs and fixtures.

- Inspection: Regularly inspect jigs and fixtures for wear, damage, or misalignment.

- Repair: Repair damaged components or replace worn parts as needed.

- Calibration and adjustment: Ensure accuracy by calibrating and adjusting jigs and fixtures periodically.

- Lubrication and cleaning: Lubricate moving parts and clean jigs and fixtures to maintain functionality.

- Documentation: Maintain records of repairs and maintenance for traceability and quality control.

6. What are the potential safety hazards associated with jigs and fixtures and how can they be mitigated?

- Pinch points: Use guards and safe operating procedures to prevent entrapment.

- Cutting hazards: Ensure sharp cutting tools are properly secured and wear appropriate safety gear.

- Electrical hazards: Use proper grounding and insulation to prevent electrical shock.

- Ergonomic hazards: Design jigs and fixtures to minimize repetitive motions and reduce strain.

- Falling objects: Securely fasten parts and components to prevent them from falling.

7. How do you stay updated on advancements in jig and fixture design and manufacturing techniques?

- Attending conferences and workshops: Participate in industry events to learn about new technologies and best practices.

- Reading technical journals and publications: Stay informed about research and developments in the field.

- Networking with industry professionals: Engage with engineers, designers, and manufacturers to exchange knowledge.

- Online research and webinars: Utilize online resources and webinars to access the latest information.

- Collaboration with vendors and suppliers: Seek input from vendors and suppliers who specialize in jig and fixture manufacturing.

8. What quality control measures do you implement to ensure the accuracy and reliability of repaired jigs and fixtures?

- Dimensional inspection: Use precision measuring instruments to verify dimensions and tolerances.

- Functional testing: Test jigs and fixtures in simulated operating conditions to ensure proper functionality.

- Calibration and certification: Calibrate and certify measuring equipment and follow established quality standards.

- Documentation: Maintain detailed records of repairs, inspections, and calibration results.

- Employee training: Provide training to repair personnel on quality control procedures.

9. How do you prioritize repairs and maintenance tasks to minimize downtime in a production environment?

- Establish a maintenance schedule: Plan regular inspections and maintenance tasks to prevent breakdowns.

- Prioritize repairs based on severity: Assess the impact of damage or malfunction and prioritize repairs accordingly.

- Use a first-in, first-out (FIFO) system: Address repairs in the order they are received.

- Communicate with production teams: Inform production teams about repair schedules to minimize disruptions.

- Cross-train repair personnel: Train multiple employees to perform repairs to avoid bottlenecks.

10. What is your experience with using computer-aided design (CAD) and computer-aided manufacturing (CAM) software in jig and fixture design and fabrication?

I am proficient in using CAD software such as SolidWorks or AutoCAD to design and model jigs and fixtures. I can create 3D models, generate drawings, and optimize designs for manufacturability. Additionally, I have experience with CAM software such as Mastercam or CAMWorks, which I use to generate toolpaths and control CNC machines for the fabrication of jigs and fixtures. This allows me to achieve high levels of precision and efficiency in the manufacturing process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig and Fixture Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig and Fixture Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jig and Fixture Repairers are responsible for maintaining and repairing jigs and fixtures used in manufacturing processes. They work closely with engineers and machinists to ensure that the jigs and fixtures are functioning properly and meeting production requirements.

1. Inspecting and Repairing Jigs and Fixtures

Jig and Fixture Repairers inspect jigs and fixtures for signs of wear, damage, or misalignment. They use precision measuring instruments to ensure that the jigs and fixtures are meeting the required specifications.

2. Troubleshooting and Problem Solving

When a jig or fixture is not functioning properly, the Jig and Fixture Repairer must troubleshoot the problem and determine the cause. They may need to consult with engineers or machinists to identify the issue and find a solution.

3. Repairing and Replacing Components

Jig and Fixture Repairers repair or replace worn or damaged components on jigs and fixtures. They may need to use welding, grinding, or other machining techniques to make the repairs.

4. Maintaining and Calibrating Jigs and Fixtures

Jig and Fixture Repairers maintain and calibrate jigs and fixtures to ensure that they are functioning properly. They may need to adjust the settings, lubricate the moving parts, or replace the batteries.

Interview Tips

Preparing for a Jig and Fixture Repairer interview can be daunting, but by following these tips you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific Jig and Fixture Repairer position. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions in advance so that you can deliver clear and concise responses.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Jig and Fixture Repairer position. This includes your knowledge of jigs and fixtures, your troubleshooting skills, and your ability to work independently.

4. Ask Questions

At the end of the interview, take the opportunity to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are eager to learn more about the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Jig and Fixture Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.