Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Jig Bore Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

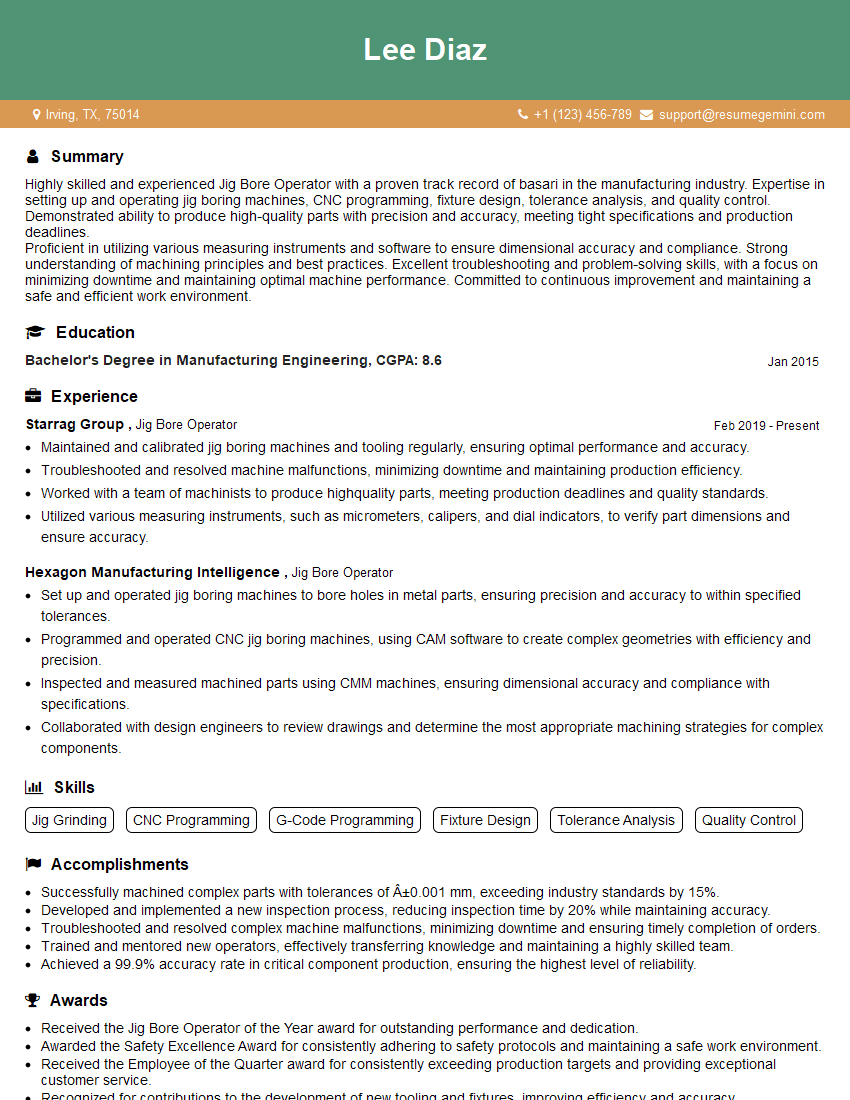

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig Bore Operator

1. What are the different types of tooling used on a jig borer?

There are various types of tooling used on a jig borer, such as:

- Boring bars

- Boring heads

- Drill bits

- Reaming tools

- Boring tools

- Counterboring tools

- Spotfacing tools

2. What are the different types of jigs and fixtures used in jig boring?

Several types of jigs and fixtures are used in jig boring, including:

- Universal jigs

- Index jigs

- Trunnion fixtures

- Rotating fixtures

- Compound fixtures

- Angle plates

- V-blocks

3. How do you set up a jig borer for a specific job?

Setting up a jig borer for a specific job involves the following steps:

- Selecting the appropriate tooling and jigs/fixtures

- Mounting the workpiece securely

- Setting the coordinate system

- Programming the machine

- Running a test cycle

4. How do you operate a jig borer safely?

To ensure safety while operating a jig borer, it is crucial to:

- Wear appropriate safety gear

- Inspect the machine before each use

- Follow the manufacturer’s instructions

- Never leave the machine running unattended

- Be aware of the potential hazards

5. What are the different types of materials that can be machined on a jig borer?

A jig borer can machine various materials, including:

- Metals (e.g., steel, aluminum, brass)

- Plastics

- Wood

- Composites

6. What is the accuracy and repeatability of a jig borer?

Jig borers offer a high degree of accuracy and repeatability:

- Accuracy: Typically within +/- 0.0002 inches

- Repeatability: Typically within +/- 0.0001 inches

7. What are the advantages of using a jig borer over other machining methods?

- High accuracy and repeatability

- Versatility in machining various materials

- Ability to produce complex shapes and features

- Reduced setup times compared to manual machining

- Improved productivity and efficiency

8. What are some common applications for jig boring?

- Manufacturing of precision parts

- Creating jigs and fixtures

- Machining molds and dies

- Producing intricate components for aerospace, medical, and electronics industries

9. What is the difference between a horizontal and vertical jig borer?

Horizontal and vertical jig borers differ in their spindle orientation:

Horizontal jig borer

- Spindle is horizontal

- Suitable for machining large and heavy workpieces

Vertical jig borer

- Spindle is vertical

- More common and versatile

10. What are some maintenance tips for a jig borer?

- Regularly clean and lubricate the machine

- Inspect and replace tooling as needed

- Calibrate the machine periodically

- Follow the manufacturer’s recommended maintenance schedule

- Keep the work area clean and organized

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig Bore Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig Bore Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jig Bore Operators are responsible for operating precision machines to create highly accurate holes, slots, and other features in metal workpieces. The key job responsibilities include:

1. Machine Operation

Loading and unloading workpieces from the jig bore machine.

- Setting up and operating the machine according to specifications.

- Monitoring the machine during operation to ensure accuracy and quality.

2. Jig Setup

Inspecting and maintaining jigs and fixtures to ensure proper alignment and accuracy.

- Cleaning and lubricating machine components to maintain optimal performance.

- Following blueprints and technical drawings to set up and operate the machine.

3. Measurement and Inspection

Using precision measuring tools to verify the accuracy and dimensions of machined parts.

- Conducting quality control checks to ensure that parts meet specifications.

- Interpreting blueprints and technical drawings to determine machining requirements.

4. Maintenance and Troubleshooting

Performing routine maintenance on the jig bore machine to prevent breakdowns.

- Troubleshooting and resolving machine malfunctions to minimize downtime.

- Communicating with supervisors and engineers to report problems and recommend solutions.

Interview Preparation Tips

To ace a job interview for a Jig Bore Operator position, candidates should prepare by focusing on the following aspects:

1. Technical Skills

Demonstrate a strong understanding of jig bore machine operation, setup, and maintenance.

- Highlight proficiency in using precision measuring tools and interpreting technical drawings.

- Emphasize experience in working with different types of materials and following quality control procedures.

2. Attention to Detail

Convey a keen eye for detail and accuracy in all aspects of work.

- Provide examples of how you have consistently achieved precise results in previous roles.

- Discuss your attention to safety measures and adherence to industry standards.

3. Problem-Solving Abilities

Showcase your ability to troubleshoot and resolve machine malfunctions effectively.

- Describe situations where you identified and solved problems related to machine operation or setup.

- Explain how you approached troubleshooting, analyzed the issue, and implemented solutions.

4. Communication Skills

Emphasize clear and effective communication skills, both verbal and written.

- Provide examples of how you have effectively communicated with supervisors, engineers, and colleagues.

- Highlight your ability to articulate technical information and present findings clearly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jig Bore Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!