Are you gearing up for an interview for a Jig Bore Tool Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jig Bore Tool Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

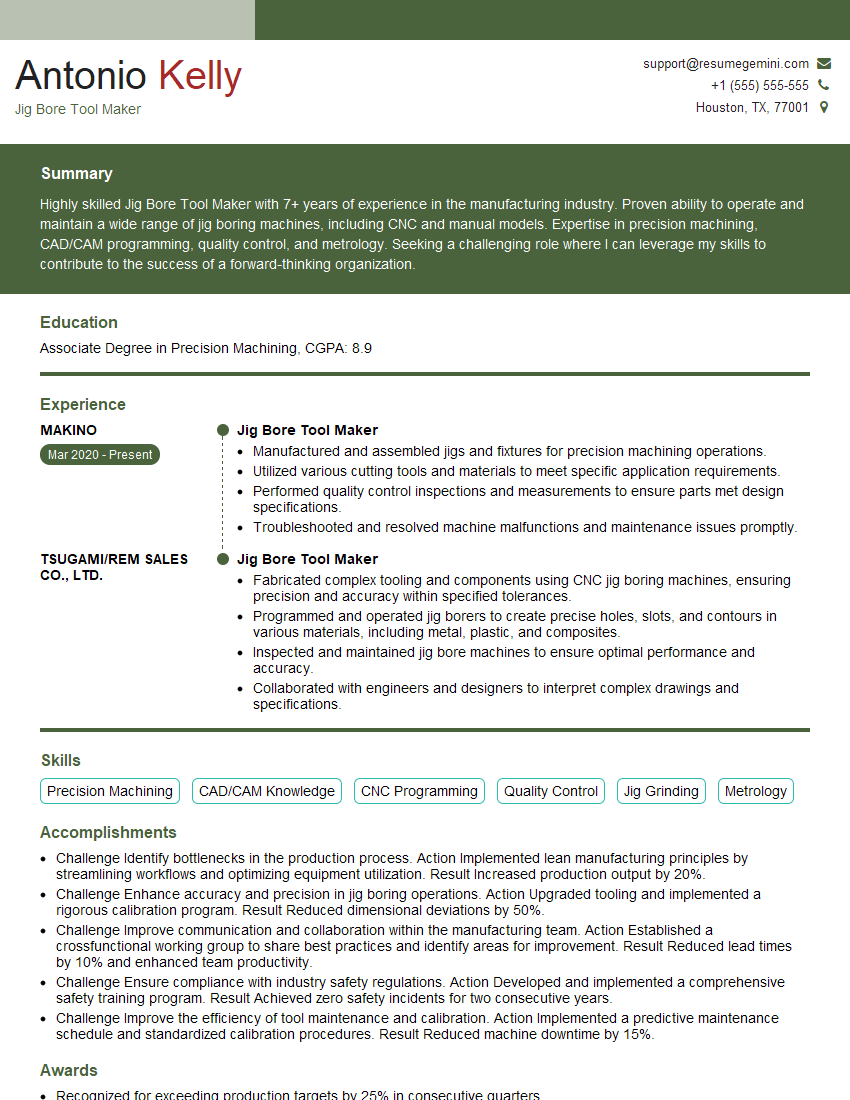

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig Bore Tool Maker

1. Describe the process of setting up and operating a jig bore machine?

The process of setting up and operating a jig bore machine involves several key steps:

- Machine preparation: Ensure the machine is level, clean, and properly lubricated.

- Workpiece setup: Secure the workpiece to the machine table using appropriate fixtures and clamps.

- Tool selection: Choose the appropriate cutting tools (e.g., drills, boring bars) based on the required bore specifications.

- Program loading: Upload the machining program into the machine’s control system.

- Tool offset setting: Establish the correct tool offsets to ensure precise positioning during machining.

- Machine operation: Start the machining process and monitor the progress, making adjustments as needed.

- Inspection: Verify the accuracy of the machined holes using appropriate measuring tools.

2. What are the different types of jig boring operations?

Hole drilling

- Creating precise holes using various drill bits.

- Ensuring accurate hole depth and location.

Boring

- Enlarging existing holes to specific diameters.

- Achieving high precision in hole size and surface finish.

Reaming

- Smoothing and finishing existing holes.

- Improving hole accuracy and surface quality.

3. How do you ensure the accuracy of machined bores?

Ensuring the accuracy of machined bores requires meticulous attention to several factors:

- Machine calibration: Regularly calibrate the machine to maintain its precision.

- Proper tool selection: Choose high-quality cutting tools that are appropriate for the material and bore specifications.

- Accurate tool offsets: Establish precise tool offsets to ensure correct tool positioning.

- Rigid workpiece setup: Secure the workpiece firmly to minimize vibrations and deflection.

- Appropriate cutting parameters: Optimize cutting speed, feed rate, and depth of cut to achieve desired accuracy.

- Meticulous inspection: Use precision measuring tools (e.g., coordinate measuring machine, hole gauge) to verify the accuracy of machined bores.

4. How do you handle complex jig boring tasks involving multiple setups?

Handling complex jig boring tasks involving multiple setups requires a systematic approach:

- Detailed planning: Plan the sequence of setups and tool changes to minimize errors.

- Precise alignment: Use precision measuring tools to align the workpiece and fixtures for each setup.

- Accurate tool offsets: Establish precise tool offsets for each setup to ensure consistency.

- Careful tool selection: Choose the appropriate tools for each setup based on the required accuracy and surface finish.

- Rigorous inspection: Inspect the workpiece after each setup to ensure accuracy and prevent cumulative errors.

5. What is the role of coolant in jig boring operations?

Coolant plays several crucial roles in jig boring operations:

- Temperature control: Cools the cutting tool and workpiece, preventing overheating and tool wear.

- Lubrication: Reduces friction between the cutting tool and workpiece, improving tool life.

- Chip removal: Flushes away metal chips and debris from the cutting zone, ensuring clean cutting conditions.

6. Describe the different types of jigs used in jig boring?

There are several types of jigs commonly used in jig boring:

- Plate jigs: Flat, precision-machined plates with holes or slots for guiding the cutting tool.

- Box jigs: Three-dimensional jigs that surround the workpiece on multiple sides, providing accurate alignment and support.

- Universal jigs: Adjustable jigs that can be customized for various workpiece shapes and sizes.

- Index jigs: Jigs that allow for precise indexing of the workpiece for multiple operations.

7. How do you ensure the safety of yourself and others while operating a jig bore machine?

Safety is paramount when operating a jig bore machine. Important measures include:

- Proper training: Receive thorough training on the machine’s operation and safety procedures.

- Personal protective equipment: Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Machine guarding: Ensure that all safety guards and covers are in place and functioning properly.

- Adequate lighting: Maintain sufficient lighting in the work area to prevent accidents.

- Emergency stop training: Familiarize yourself with the emergency stop button and practice its use.

8. How do you maintain a jig bore machine for optimal performance?

Regular maintenance is essential for maintaining optimal machine performance:

- Cleaning: Regularly clean the machine and remove any chips or debris.

- Lubrication: Lubricate all moving parts according to the manufacturer’s recommendations.

- Calibration: Calibrate the machine periodically to ensure accuracy and repeatability.

- Tool maintenance: Sharpen or replace cutting tools as needed to maintain cutting efficiency.

- Spindle maintenance: Check the condition of the spindle and bearings regularly and replace as necessary.

9. Describe your experience in using different types of measuring instruments in jig boring operations.

In jig boring operations, I am proficient in using various measuring instruments to ensure accuracy and precision:

- Dial indicators: Measuring small linear and angular displacements.

- Coordinate measuring machines (CMMs): Measuring complex workpiece geometries and verifying dimensions.

- Hole gauges: Verifying the accuracy of hole diameters, depths, and surface finishes.

- Optical comparators: Comparing the workpiece to a reference template or master part.

- Micrometers and calipers: Measuring linear dimensions with high accuracy.

10. Discuss the importance of quality control in jig boring operations.

Quality control is crucial in jig boring operations to ensure the accuracy, precision, and reliability of machined parts:

- Inspection: Regularly inspecting workpieces at various stages to identify and address any deviations from specifications.

- Statistical process control (SPC): Monitoring and analyzing data to identify and control process variations and maintain quality.

- Calibration and verification: Calibrating and verifying measuring instruments and equipment to ensure accurate measurements.

- Corrective actions: Taking timely and effective corrective actions to prevent or address quality issues.

- Traceability: Maintaining records and documentation to trace products and processes for quality assurance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig Bore Tool Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig Bore Tool Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jig Bore Tool Maker is responsible for making precision jigs and fixtures used in the manufacturing process. This position is crucial in ensuring the accuracy and quality of manufactured parts.

1. Designing and Building Jigs and Fixtures

This involves creating custom jigs and fixtures used to hold and guide cutting tools during machining operations. These tools ensure precise alignment and repeatability, resulting in consistent product quality.

2. Operating Jig Boring Machines

Jig Bore Tool Makers operate jig boring machines to create precise holes and slots in workpieces. They use specialized tooling and techniques to achieve the required tolerances and surface finishes.

3. Maintaining and Inspecting Equipment

Regular maintenance and inspection of jig boring machines are essential to ensure optimal performance. Tool Makers are responsible for cleaning, lubricating, and adjusting machines, as well as performing preventative maintenance to minimize downtime.

4. Quality Control

Jig Bore Tool Makers are involved in the quality control process. They inspect finished parts to ensure they meet specifications and make adjustments to tools or processes as needed.

5. Troubleshooting and Problem-Solving

In the event of any issues with jigs, fixtures, or machines, Tool Makers troubleshoot and resolve problems promptly. Their understanding of the manufacturing process and equipment allows them to quickly identify and rectify errors.

Interview Tips

Preparing for a Jig Bore Tool Maker interview requires a combination of technical knowledge and presentation skills. Here are some interview preparation tips and hacks:

1. Research the Company and Position

Thoroughly research the company and specific role you’re applying for. This will give you insights into their products, processes, and company culture. Tailor your answers to demonstrate how your skills and experience align with the company’s needs.

2. Practice Common Interview Questions

Anticipate common interview questions related to your technical skills, experience with jig boring machines, and quality control processes. Practice answering these questions clearly and concisely, highlighting your strengths and accomplishments.

3. Showcase Your Problem-Solving Abilities

In the interview, emphasize your problem-solving skills and ability to troubleshoot issues with jigs, fixtures, and machines. Share examples from your previous experience where you successfully resolved challenges.

4. Discuss Quality Control Procedures

Highlight your understanding of quality control procedures and your commitment to delivering products that meet or exceed specifications. Describe your experience with inspection techniques and your attention to detail in ensuring product accuracy.

5. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows your interest in the company and the role. Prepare questions about the company’s manufacturing processes, quality standards, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jig Bore Tool Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.