Feeling lost in a sea of interview questions? Landed that dream interview for Jig Boring Machine Operator for Metal but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Jig Boring Machine Operator for Metal interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

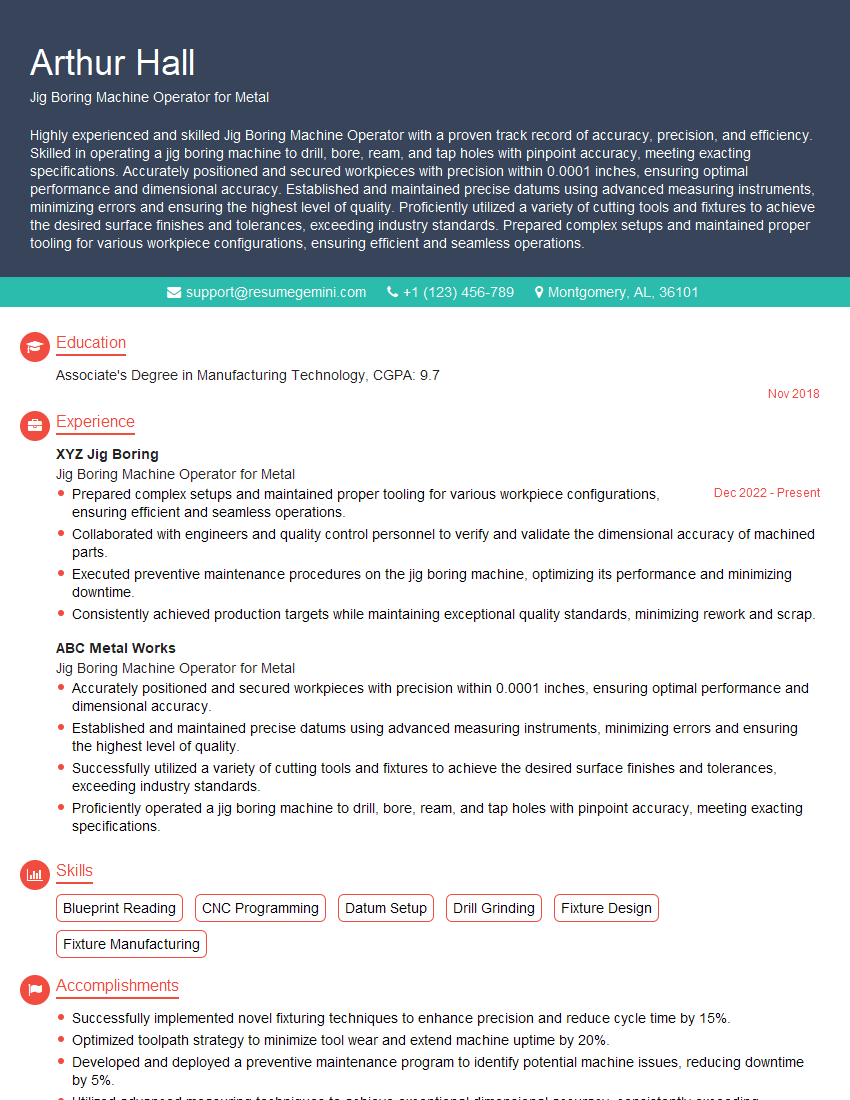

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jig Boring Machine Operator for Metal

1. What are the main components of a jig boring machine?

A jig boring machine consists of the following main components:

- Base: The base is a rigid and stable structure that supports the entire machine.

- Column: The column is a vertical member that is mounted on the base.

- Headstock: The headstock is mounted on the column and contains the spindle, which rotates the cutting tool.

- Table: The table is mounted on the base and supports the workpiece.

- Saddle: The saddle is mounted on the table and moves the workpiece in the X and Y axes.

- Knee: The knee is mounted on the saddle and moves the workpiece in the Z axis.

- Control panel: The control panel is used to operate the machine.

2. What are the different types of jig boring machines?

Vertical

- Column and knee type machine

- Ram and table type machine

Horizontal

- Floor type

- Bench type

Boring units

- For boring holes on narrow surfaces

- For boring holes in large components

3. What are the different types of cutting tools used in jig boring machines?

The different types of cutting tools used in jig boring machines include:

- Boring bars: Boring bars are used to bore holes in metal.

- Drills: Drills are used to create holes in metal.

- End mills: End mills are used to mill metal surfaces.

- Reaming tools: Reaming tools are used to finish holes in metal.

- Tapping tools: Tapping tools are used to create threads in metal.

4. What are the different operations that can be performed on a jig boring machine?

The different operations that can be performed on a jig boring machine include:

- Boring: Boring is the process of creating holes in metal.

- Drilling: Drilling is the process of creating holes in metal.

- Milling: Milling is the process of removing metal from a surface.

- Reaming: Reaming is the process of finishing holes in metal.

- Tapping: Tapping is the process of creating threads in metal.

- Facing: Facing is the process of creating a flat surface on a metal workpiece.

- Profiling: Profiling is the process of creating a specific shape on a metal workpiece.

5. What are the advantages of using a jig boring machine?

The advantages of using a jig boring machine include:

- High precision: Jig boring machines are capable of producing high-precision holes and surfaces.

- Repeatability: Jig boring machines can repeat the same operation multiple times with high accuracy.

- Versatility: Jig boring machines can be used to perform a variety of operations, including boring, drilling, milling, reaming, and tapping.

- Efficiency: Jig boring machines are efficient machines that can produce high-quality workpieces in a short amount of time.

6. What are the disadvantages of using a jig boring machine?

The disadvantages of using a jig boring machine include:

- High cost: Jig boring machines are expensive machines to purchase and maintain.

- Complex setup: Jig boring machines can be complex to set up and operate.

- Limited workpiece size: Jig boring machines have a limited workpiece size capacity.

7. What are the safety precautions that must be taken when operating a jig boring machine?

The safety precautions that must be taken when operating a jig boring machine include:

- Wear appropriate safety gear: This includes safety glasses, earplugs, and gloves.

- Be aware of the machine’s moving parts: Keep your hands and body away from the machine’s moving parts.

- Use sharp cutting tools: Sharp cutting tools will produce cleaner cuts and reduce the risk of accidents.

- Secure the workpiece properly: The workpiece must be securely clamped to the table to prevent it from moving during the operation.

- Follow the manufacturer’s instructions: Always follow the manufacturer’s instructions for operating the machine.

8. What are the maintenance procedures that must be performed on a jig boring machine?

The maintenance procedures that must be performed on a jig boring machine include:

- Clean the machine regularly: The machine should be cleaned regularly to remove chips and other debris.

- Lubricate the machine regularly: The machine should be lubricated regularly to keep it running smoothly.

- Inspect the machine regularly: The machine should be inspected regularly to identify any potential problems.

- Calibrate the machine regularly: The machine should be calibrated regularly to ensure that it is producing accurate results.

9. What are the troubleshooting procedures that can be performed on a jig boring machine?

The troubleshooting procedures that can be performed on a jig boring machine include:

- Identify the problem: The first step is to identify the problem that is causing the machine to malfunction.

- Check the power supply: Make sure that the machine is properly connected to a power source.

- Check the hydraulic system: Make sure that the hydraulic system is functioning properly.

- Check the control system: Make sure that the control system is functioning properly.

- Check the cutting tools: Make sure that the cutting tools are sharp and in good condition.

- Check the workpiece: Make sure that the workpiece is properly secured to the table.

10. What are the skills and experience that are required for a jig boring machine operator?

The skills and experience that are required for a jig boring machine operator include:

- Knowledge of jig boring machines: The operator must have a thorough knowledge of the operation, maintenance, and troubleshooting of jig boring machines.

- Experience in operating jig boring machines: The operator must have experience in operating jig boring machines to produce high-quality workpieces.

- Ability to read and interpret blueprints: The operator must be able to read and interpret blueprints to determine the specifications of the workpiece that is to be produced.

- Ability to set up and operate cutting tools: The operator must be able to set up and operate cutting tools to produce the desired results.

- Ability to work independently: The operator must be able to work independently and follow instructions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jig Boring Machine Operator for Metal.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jig Boring Machine Operator for Metal‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Jig Boring Machine Operators for Metal are responsible for operating and maintaining jig boring machines used in the production of metal parts. Their key responsibilities include:

1. Machine Operation

Setting up and operating jig boring machines to produce precision holes, slots, and other features in metal components.

- Following blueprints and specifications to determine machine settings and tooling.

- Loading and securing workpieces in the machine.

- Selecting and mounting appropriate cutting tools.

- Monitoring machine operation and making adjustments as needed.

- Performing quality control checks on finished parts.

2. Machine Maintenance

Maintaining and calibrating jig boring machines to ensure optimal performance and accuracy.

- Checking and replacing worn or damaged components.

- Lubricating and cleaning the machine.

- Calibrating the machine to ensure precision.

- Troubleshooting and resolving machine malfunctions.

3. Workpiece Handling

Handling and transporting metal workpieces safely and efficiently.

- Using proper lifting techniques to move heavy workpieces.

- Loading and unloading workpieces from the machine.

- Storing workpieces securely to prevent damage.

4. Quality Control

Inspecting finished parts to ensure they meet required tolerances and specifications.

- Using precision measuring tools to check dimensions and tolerances.

- Identifying and correcting any defects or discrepancies.

- Maintaining records of inspection results.

Interview Tips

To prepare for an interview for a Jig Boring Machine Operator for Metal position, candidates should consider the following tips:

1. Research the Company and Position

Research the company’s products, services, and industry reputation. Review the job description thoroughly to understand the specific requirements of the position.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on trends and technologies.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Quantify your accomplishments and provide specific examples of your work.

- Highlight your experience in operating jig boring machines and producing precision metal parts.

- Describe your knowledge of machine maintenance and calibration.

- Mention any experience with quality control and inspection procedures.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications. Practice answering these questions clearly and concisely.

- Why are you interested in this position?

- What is your experience with jig boring machines?

- How do you ensure the accuracy and precision of your work?

- What are your strengths and weaknesses as a Jig Boring Machine Operator?

4. Dress Professionally and Arrive Punctually

Dress appropriately for the interview and arrive on time. First impressions matter, so make sure you present yourself in a professional manner.

- Wear clean and pressed business attire.

- Arrive at the interview location at least 15 minutes early.

- Be polite and respectful to the interviewer and any other staff members you encounter.

5. Follow Up

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and consideration. You can also reiterate your interest in the position and highlight any additional qualifications or experience that you may have forgotten to mention during the interview.

- Send the thank-you note within 24 hours of the interview.

- Personalize the note and address it to the interviewer by name.

- Proofread your note carefully before sending it.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jig Boring Machine Operator for Metal interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!