Feeling lost in a sea of interview questions? Landed that dream interview for Joint Cleaning and Grooving Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Joint Cleaning and Grooving Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

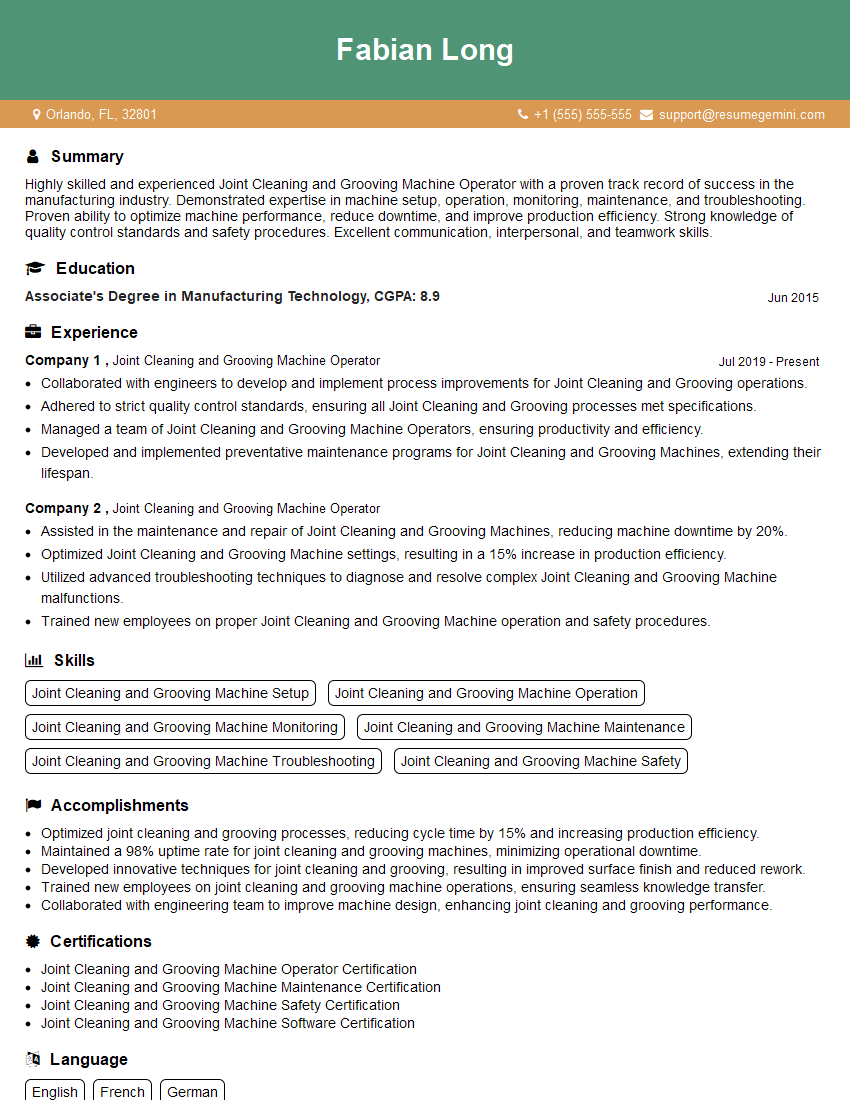

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Joint Cleaning and Grooving Machine Operator

1. Explain what are the key responsibilities of a Joint Cleaning and Grooving Machine Operator?

The key responsibilities of a Joint Cleaning and Grooving Machine Operator include:

- Maintaining and preparing the machine for operation, which includes conducting daily maintenance checks and calibrating the machine.

- Loading and unloading the machine, ensuring that it is fed with the correct materials and that the finished product is handled properly.

- Monitoring the machine during operation, making sure that it is functioning correctly and that the quality of the output is maintained.

- Making necessary adjustments to the machine during operation, ensuring that the output meets the required specifications.

- Troubleshooting and resolving any issues that may arise during operation, ensuring minimal downtime and maintaining productivity.

- Cleaning and maintaining the machine after operation, ensuring that it is ready for the next production run.

2. Describe the different types of joints that can be cleaned and grooved using this machine.

The types of joints that can be cleaned and grooved using this machine include:

- Butt joints, which involve joining two pieces of material together edge-to-edge.

- Lap joints, which involve overlapping two pieces of material and joining them together.

- T-joints, which involve joining a piece of material perpendicularly to another piece.

- Mitre joints, which involve joining two pieces of material at an angle.

- Dovetail joints, which involve interlocking two pieces of material with a series of trapezoidal-shaped cuts.

3. What are the safety precautions that need to be taken when operating a joint cleaning and grooving machine?

The safety precautions that need to be taken when operating a joint cleaning and grooving machine include:

- Wearing appropriate safety gear such as safety glasses, gloves, and earplugs.

- Ensuring that the machine is properly grounded and that all electrical connections are secure.

- Keeping the work area clean and free of debris.

- Never reaching into the machine while it is running.

- Shutting off the machine and disconnecting it from power before performing any maintenance or repairs.

4. How do you ensure that the finished product meets the required specifications?

To ensure that the finished product meets the required specifications, I follow these steps:

- Verifying the specifications of the finished product before starting the machine.

- Calibrating the machine according to the manufacturer’s instructions.

- Monitoring the machine during operation and making adjustments as needed.

- Inspecting the finished product and measuring it to verify that it meets the specifications.

- Re-calibrating the machine if necessary.

5. Describe how you troubleshoot and resolve issues that may arise during the operation of the machine.

When troubleshooting and resolving issues that may arise during the operation of the machine, I follow these steps:

- Identify the problem by observing the machine’s behavior and the finished product.

- Refer to the manufacturer’s manual for possible causes of the problem.

- Check the machine for any loose connections or damaged parts.

- Make necessary adjustments to the machine or replace any damaged parts.

- Test the machine to verify that the problem has been resolved.

6. How do you maintain the machine to ensure optimal performance and longevity?

To maintain the machine and ensure optimal performance and longevity, I follow these steps:

- Cleaning the machine regularly to remove any dust or debris.

- Lubricating the machine’s moving parts according to the manufacturer’s instructions.

- Inspecting the machine’s electrical connections and making sure they are secure.

- Calibrating the machine regularly to ensure accuracy.

- Following the manufacturer’s recommended maintenance schedule.

7. How do you stay up-to-date with the latest advancements in joint cleaning and grooving technology?

To stay up-to-date with the latest advancements in joint cleaning and grooving technology, I:

- Attend industry trade shows and conferences.

- Read industry publications and online resources.

- Network with other professionals in the field.

- Take continuing education courses.

8. Describe a time when you had to go above and beyond to meet a customer’s needs.

One time when I had to go above and beyond to meet a customer’s needs was when I was working on a very large and complex project. The customer had a very tight deadline and needed the project to be completed within a very short time frame. I worked long hours and even came in on the weekend to ensure that the project was completed on time and to the customer’s satisfaction. The customer was very happy with my work and even sent me a thank-you note.

9. What are your strengths and weaknesses as a joint cleaning and grooving machine operator?

Some of my strengths as a joint cleaning and grooving machine operator include:

- My attention to detail.

- My ability to work independently and as part of a team.

- My ability to learn new things quickly.

- My commitment to safety.

One of my weaknesses is that I can be a bit of a perfectionist, and I sometimes have to remind myself that it’s okay to make mistakes. However, I am always willing to learn from my mistakes and improve my skills.

10. Why are you interested in working as a joint cleaning and grooving machine operator for our company?

I am interested in working as a joint cleaning and grooving machine operator for your company because I am impressed by your company’s commitment to quality and customer service. I believe that my skills and experience would be a valuable asset to your team, and I am eager to learn more about your company and how I can contribute to your success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Joint Cleaning and Grooving Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Joint Cleaning and Grooving Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Joint Cleaning and Grooving Machine Operators are responsible for operating machines that clean and groove joints in concrete and other materials. Their key responsibilities include:

- Inspecting joints to determine the proper cleaning and grooving methods

- Preparing machinery and materials for the cleaning and grooving process

- Operating joint cleaning and grooving machines to remove old sealant, debris, or uneven surfaces from joints

- Adjusting machine settings and parameters for optimal performance

- Monitoring the progress of the cleaning and grooving process to ensure accuracy and precision

- Cleaning and maintaining joint cleaning and grooving machines to ensure optimal performance

- Ensuring that all safety protocols and procedures are strictly adhered to

By performing these duties, Joint Cleaning and Grooving Machine Operators play a crucial role in maintaining the structural integrity and aesthetic appeal of various concrete structures, including roads, bridges, buildings, and parking areas.

Interview Tips

Preparing for an interview for a Joint Cleaning and Grooving Machine Operator position requires careful preparation and a thorough understanding of the role’s key responsibilities. Here are some tips to help you ace the interview:

1. Research the Job Description

- Review the job description thoroughly to understand the specific requirements and expectations of the position.

- Identify the essential qualifications, skills, and experience that the employer is seeking.

- Prepare examples from your previous work experience that demonstrate your proficiency in these areas.

2. Highlight Your Skills and Experience

- Emphasize your experience in operating joint cleaning and grooving machines, including any specialized skills or techniques you possess.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Explain how your skills and experience align with the job requirements and can benefit the organization.

3. Prepare for Common Interview Questions

- Practice answering common interview questions related to your skills, experience, and qualifications.

- Prepare specific examples and anecdotes that illustrate your abilities and work ethic.

- Consider potential questions about your knowledge of industry best practices and safety procedures.

4. Ask Informed Questions

- Prepare thoughtful questions to ask the interviewer about the company, the role, and the industry.

- Asking informed questions demonstrates your interest in the position and your desire to learn more about the organization.

- Questions can also help you assess the company’s culture and values.

5. Dress Professionally and Arrive on Time

- First impressions matter, so dress professionally for the interview.

- Arrive on time to show respect for the interviewer and the organization.

- Being punctual and well-dressed conveys professionalism and attention to detail.

Next Step:

Now that you’re armed with the knowledge of Joint Cleaning and Grooving Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Joint Cleaning and Grooving Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini