Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Joint Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

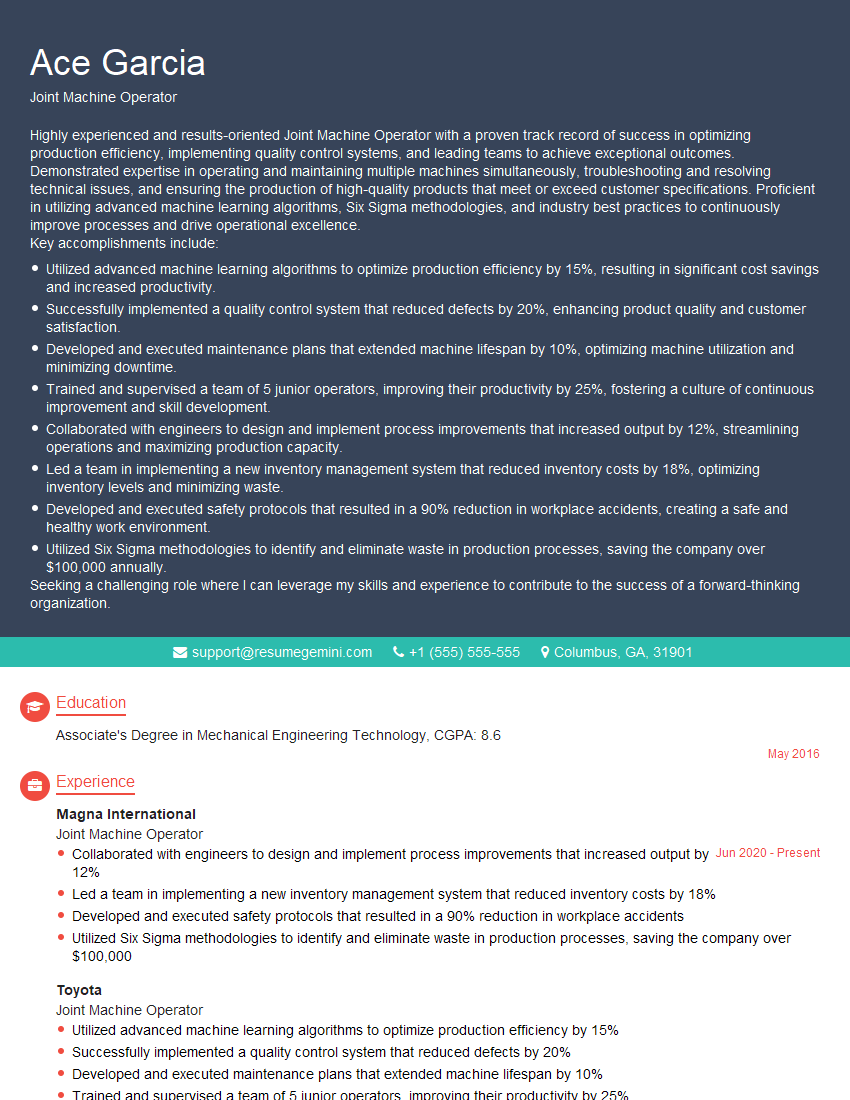

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Joint Machine Operator

1. What are the primary responsibilities of a Joint Machine Operator?

Primary responsibilities include:

- Operating and monitoring a variety of machines, including jointers, planers, and saws

- Setting up and adjusting machines to ensure accurate and efficient operation

- Inspecting raw materials and finished products to ensure quality

- Troubleshooting and resolving machine problems

- Maintaining a clean and safe work area

2. Describe the different types of jointing machines you have experience with.

Types of Jointing Machines

- Hand-held jointers

- Benchtop jointers

- Floor model jointers

- Wide-belt sanders

Experience with Different Types of Jointing Machines

- I have extensive experience with all types of jointing machines, including hand-held, benchtop, floor model, and wide-belt sanders.

- I am proficient in operating these machines to create a variety of joints, including edge joints, face joints, and miter joints.

- I have a strong understanding of the proper setup and adjustment of these machines to ensure accurate and efficient operation.

3. What are the safety precautions that must be taken when operating a jointer machine?

Safety precautions include:

- Always wear appropriate safety gear, including eye protection, hearing protection, and gloves

- Never operate a jointer machine while under the influence of alcohol or drugs

- Keep hands and fingers away from the cutting blades

- Never reach over the cutting blades

- Always use a push block or featherboard when feeding material through the machine

- Never leave the machine running unattended

- Always disconnect the machine from the power source before performing any maintenance or repairs

4. How do you troubleshoot a jointer machine that is not cutting properly?

Troubleshooting steps include:

- Check the cutting blades for sharpness and damage

- Adjust the cutting blades to the correct height and angle

- Check the fence for alignment

- Check the infeed and outfeed tables for flatness and levelness

- Check the belts and pulleys for wear and damage

- Check the electrical connections

- If the problem persists, consult the machine manufacturer’s manual or contact a qualified technician

5. What are the different types of planer machines you have experience with?

Types of Planer Machines

- Hand-held planers

- Benchtop planers

- Floor model planers

- Wide-belt sanders

Experience with Different Types of Planer Machines

- I have extensive experience with all types of planer machines, including hand-held, benchtop, floor model, and wide-belt sanders.

- I am proficient in operating these machines to create a variety of surfaces, including flat surfaces, beveled surfaces, and curved surfaces.

- I have a strong understanding of the proper setup and adjustment of these machines to ensure accurate and efficient operation.

6. What are the safety precautions that must be taken when operating a planer machine?

Safety precautions include:

- Always wear appropriate safety gear, including eye protection, hearing protection, and gloves

- Never operate a planer machine while under the influence of alcohol or drugs

- Keep hands and fingers away from the cutting blades

- Never reach over the cutting blades

- Always use a push block or featherboard when feeding material through the machine

- Never leave the machine running unattended

- Always disconnect the machine from the power source before performing any maintenance or repairs

7. How do you troubleshoot a planer machine that is not cutting properly?

Troubleshooting steps include:

- Check the cutting blades for sharpness and damage

- Adjust the cutting blades to the correct height and angle

- Check the fence for alignment

- Check the infeed and outfeed tables for flatness and levelness

- Check the belts and pulleys for wear and damage

- Check the electrical connections

- If the problem persists, consult the machine manufacturer’s manual or contact a qualified technician

8. What are the different types of saw machines you have experience with?

Types of Saw Machines

- Table saws

- Circular saws

- Miter saws

- Band saws

- Scroll saws

Experience with Different Types of Saw Machines

- I have extensive experience with all types of saw machines, including table saws, circular saws, miter saws, band saws, and scroll saws.

- I am proficient in operating these machines to create a variety of cuts, including straight cuts, angled cuts, and curved cuts.

- I have a strong understanding of the proper setup and adjustment of these machines to ensure accurate and efficient operation.

9. What are the safety precautions that must be taken when operating a saw machine?

Safety precautions include:

- Always wear appropriate safety gear, including eye protection, hearing protection, and gloves

- Never operate a saw machine while under the influence of alcohol or drugs

- Keep hands and fingers away from the cutting blade

- Never reach over the cutting blade

- Always use a push stick or push block when feeding material through the machine

- Never leave the machine running unattended

- Always disconnect the machine from the power source before performing any maintenance or repairs

10. How do you troubleshoot a saw machine that is not cutting properly?

Troubleshooting steps include:

- Check the cutting blade for sharpness and damage

- Adjust the cutting blade to the correct height and angle

- Check the fence for alignment

- Check the infeed and outfeed tables for flatness and levelness

- Check the belts and pulleys for wear and damage

- Check the electrical connections

- If the problem persists, consult the machine manufacturer’s manual or contact a qualified technician

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Joint Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Joint Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Joint Machine Operators are responsible for operating and maintaining machinery used in the fabrication and assembly of products. They may also be responsible for inspecting and testing products to ensure they meet quality standards.

1. Machine Operation

Joint Machine Operators must be able to safely and efficiently operate a variety of machines, including lathes, mills, drills, and grinders.

- Set up and operate machines according to specifications.

- Monitor machines and make adjustments as needed.

2. Material Handling

Joint Machine Operators must be able to safely handle and move materials, including metal, plastic, and wood.

- Load and unload materials from machines.

- Move materials around the work area.

3. Quality Control

Joint Machine Operators must be able to inspect and test products to ensure they meet quality standards.

- Inspect products for defects.

- Test products to ensure they meet specifications.

4. Maintenance

Joint Machine Operators must be able to perform basic maintenance on machines, including cleaning, lubrication, and minor repairs.

- Clean and lubricate machines.

- Perform minor repairs on machines.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Answering Interview Questions

One of the best ways to prepare for an interview is to practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Use the STAR method to answer questions.

- Prepare for questions about your skills, experience, and qualifications.

- Practice answering questions about why you are interested in the job and why you are the best person for the job.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing clothes that are too revealing or too casual.

4. Be Punctual

Being on time for your interview is important. It shows that you are respectful of the interviewer’s time and that you are serious about the job.

- Give yourself plenty of time to get to the interview.

- If you are running late, call the interviewer to let them know.

- Do not be more than 15 minutes late for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Joint Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.