Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Joint Sealer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

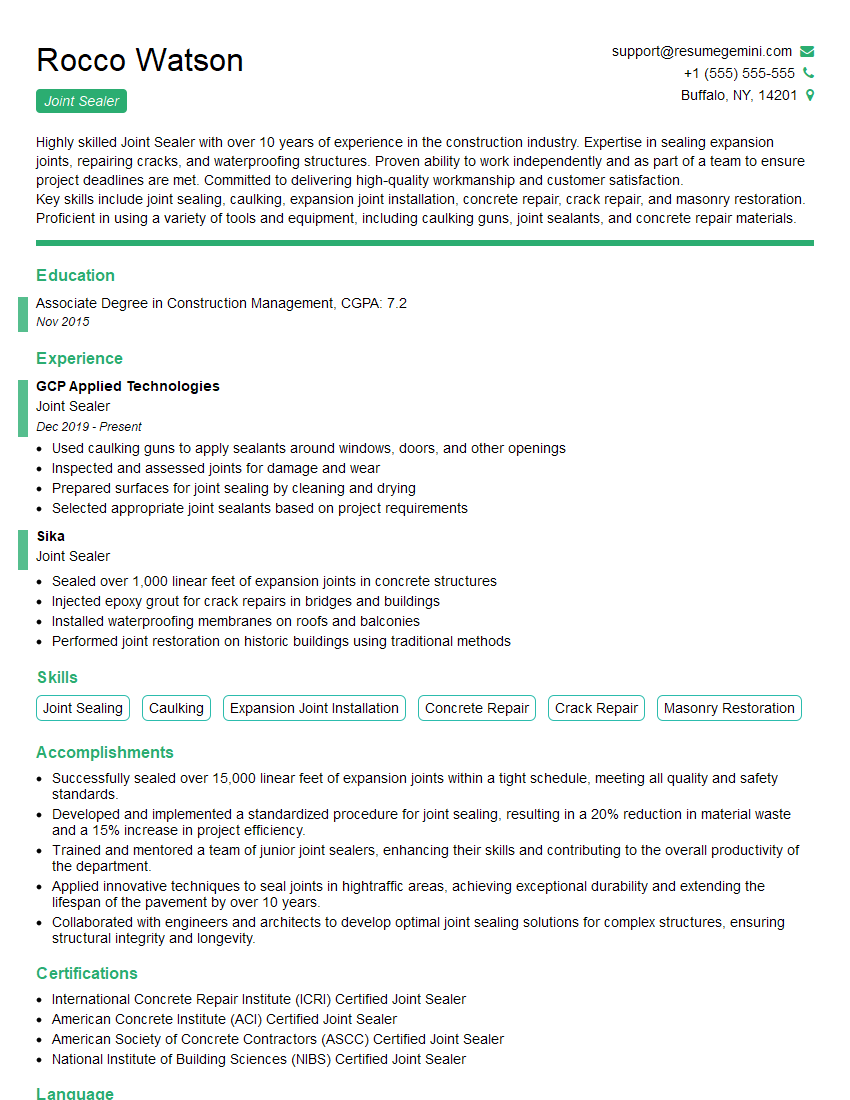

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Joint Sealer

1. Explain the different types of joint sealants and their applications?

There are various types of joint sealants, each with specific applications depending on the surface, desired performance, and environmental conditions.

- Silicone-based sealants: Known for their flexibility, water resistance, and resistance to extreme temperatures, silicone sealants are ideal for sealing joints in bathrooms, kitchens, windows, and exterior facades.

- Polyurethane sealants: These sealants offer high strength and durability, making them suitable for sealing expansion joints, concrete joints, and industrial applications.

- Acrylic sealants: Acrylic sealants are water-based and easy to apply, and they provide a durable, paintable seal. They are commonly used for sealing joints in drywall, baseboards, and trim.

- Polysulfide sealants: Polysulfide sealants are solvent-based and offer exceptional chemical resistance, making them suitable for sealing joints in fuel tanks, pipelines, and other industrial applications.

- Butyl sealants: Butyl sealants are non-hardening and provide a flexible seal. They are commonly used for sealing gaps around windows and doors, and in automotive applications.

2. Describe the proper surface preparation techniques for joint sealing?

Pre-Application Cleaning:

- Remove all dirt, dust, grease, and any loose debris from the surfaces to be sealed.

- Use a degreaser or solvent to remove any oils or contaminants that may interfere with adhesion.

Priming (if necessary):

- For certain surfaces and sealants, a primer may be required to enhance adhesion and durability.

- Apply the primer according to the manufacturer’s instructions.

Masking (optional):

- Applying masking tape around the joint edges can help achieve a clean and professional finish.

Joint Backing (recommended):

- To prevent the sealant from sagging or falling out of deep joints, use a joint backing material.

3. How do you determine the correct joint width and depth for sealant application?

- Consult the sealant manufacturer’s specifications or industry standards for the recommended joint dimensions.

- Consider the movement capability of the sealant and the expected movement of the joint.

- For most applications, a joint width-to-depth ratio of 2:1 is recommended.

- For joints subject to high movement, a wider joint width may be required.

4. Explain the factors affecting the durability of joint sealants?

- Joint design: Proper joint design, including the correct width, depth, and backing, ensures the sealant can effectively accommodate movement and prevent failure.

- Sealant selection: Choosing the appropriate sealant type based on the specific application, joint conditions, and environmental factors is crucial.

- Surface preparation: Thorough cleaning and preparation of the surfaces before sealant application ensures a strong and durable bond.

- Proper application: Following the manufacturer’s instructions and using the correct application techniques is essential for optimal performance.

- Environmental conditions: Factors such as temperature, humidity, and UV exposure can affect the sealant’s durability and performance.

- Maintenance: Regular inspection and maintenance of the sealed joints can extend the sealant’s lifespan.

5. Discuss the importance of proper tooling and finishing techniques in joint sealing?

Proper tooling and finishing techniques are essential for achieving a professional and long-lasting seal.

Tooling:

- Use the appropriate tooling, such as a sealant gun, trowel, or backer rod, to apply and shape the sealant.

- Tooling helps to ensure proper joint filling, consolidation, and bonding.

Finishing:

- After applying the sealant, smooth and finish the surface using a tool or finger.

- Creating a smooth, even finish helps prevent dirt accumulation and improves the sealant’s aesthetics.

6. What safety precautions should be taken when working with joint sealants?

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator if necessary.

- Ensure proper ventilation in the work area to avoid inhalation of fumes.

- Handle and store sealants according to the manufacturer’s instructions.

- Be aware of the potential hazards associated with the specific sealant being used.

- Follow all safety guidelines and regulations.

7. Describe the different methods of sealant removal and their applications?

- Mechanical removal: Using tools such as a utility knife, scraper, or wire brush to physically remove the sealant.

- Chemical removal: Applying a chemical sealant remover to dissolve and soften the sealant, making it easier to remove.

- Heat removal: Using a heat gun or torch to soften the sealant and scrape it away.

8. Explain the role of joint sealants in building envelope performance?

Joint sealants play a vital role in maintaining the integrity and performance of the building envelope.

- Waterproofing: Sealants prevent water infiltration through joints, protecting the building from moisture damage.

- Air infiltration: Sealants reduce air leakage through joints, improving energy efficiency and occupant comfort.

- Thermal insulation: Sealants help maintain the thermal envelope, reducing heat loss or gain.

- Acoustics: Sealants can contribute to noise reduction by blocking sound transmission through joints.

- Movement accommodation: Sealants allow for movement between building components, preventing damage caused by expansion, contraction, or seismic activity.

9. Discuss the latest trends and advancements in joint sealant technology?

- High-performance sealants: Sealants with improved durability, flexibility, and resistance to extreme conditions.

- Sustainable sealants: Sealants formulated with environmentally friendly materials and reduced VOC emissions.

- Self-leveling sealants: Sealants that automatically level and smooth themselves, reducing the need for tooling.

- Smart sealants: Sealants with sensors that can monitor joint performance and provide real-time data.

- Nanotechnology in sealants: The incorporation of nanomaterials to enhance sealant properties, such as adhesion, flexibility, and durability.

10. How do you stay updated with the latest industry best practices and advancements in joint sealing?

- Attend industry conferences, workshops, and training sessions.

- Read trade publications, technical articles, and manufacturer literature.

- Participate in industry organizations and online forums.

- Consult with experts, such as architects, engineers, and sealant manufacturers.

- Stay informed about new regulations and building codes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Joint Sealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Joint Sealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Joint Sealers are responsible for sealing joints and seams to prevent water, air, and noise from penetrating through. They also perform other tasks to ensure the integrity of joints and seams.

1. Preparing Surfaces

Joint Sealers prepare surfaces for sealing by cleaning them thoroughly and removing any debris, dirt or grease.

- Cleaning surfaces with solvents, detergents, or abrasive pads

- Removing loose or damaged materials

2. Applying Sealant

Joint Sealers apply sealant to surfaces with a variety of tools, such as caulking guns, putty knives, or brushes. Different types of sealants are used depending on the application, with some being more flexible, heat-resistant, or waterproof than others.

- Choosing the correct sealant for the application

- Applying sealant evenly and smoothly

3. Finishing Joints

Joint Sealers finish joints by smoothing or tooling the sealant to create a neat and professional appearance. They also take steps to ensure that the sealant adheres properly and will not fail prematurely.

- Smoothing or tooling the sealant with a variety of tools

- Removing excess sealant and cleaning up the work area

4. Inspecting Joints

Joint Sealers inspect joints regularly to ensure that they are in good condition and performing as intended. They also make any necessary repairs or adjustments to ensure the ongoing integrity of the joints.

- Checking for cracks, gaps, or other signs of damage

- Making repairs or adjustments as needed

Interview Tips

To ace an interview for a Joint Sealer position, there are several tips you should follow:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company culture, the role you will be expected to play, and the experience and qualifications they are looking for in a candidate.

- Visit the company website

- Read industry news and articles

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked during an interview for a Joint Sealer position. Take the time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about your experience with sealing joints and seams

- What types of sealants are you familiar with

- How do you ensure that a joint is properly sealed

3. Be Prepared to Discuss Your Experience

In addition to answering common interview questions, you should also be prepared to discuss your experience in detail. This includes your experience with sealing joints and seams, the types of sealants you have used, and the projects you have worked on. Be sure to highlight your skills and abilities, and how they can benefit the company.

- Talk about your experience with different types of joints and seams

- Discuss the different types of sealants you have used and their applications

4. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you are interested in the position and that you are serious about being a part of the team.

- Ask about the company’s culture

- Ask about the specific projects you will be working on

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Joint Sealer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Joint Sealer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.