Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Joint Yarner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

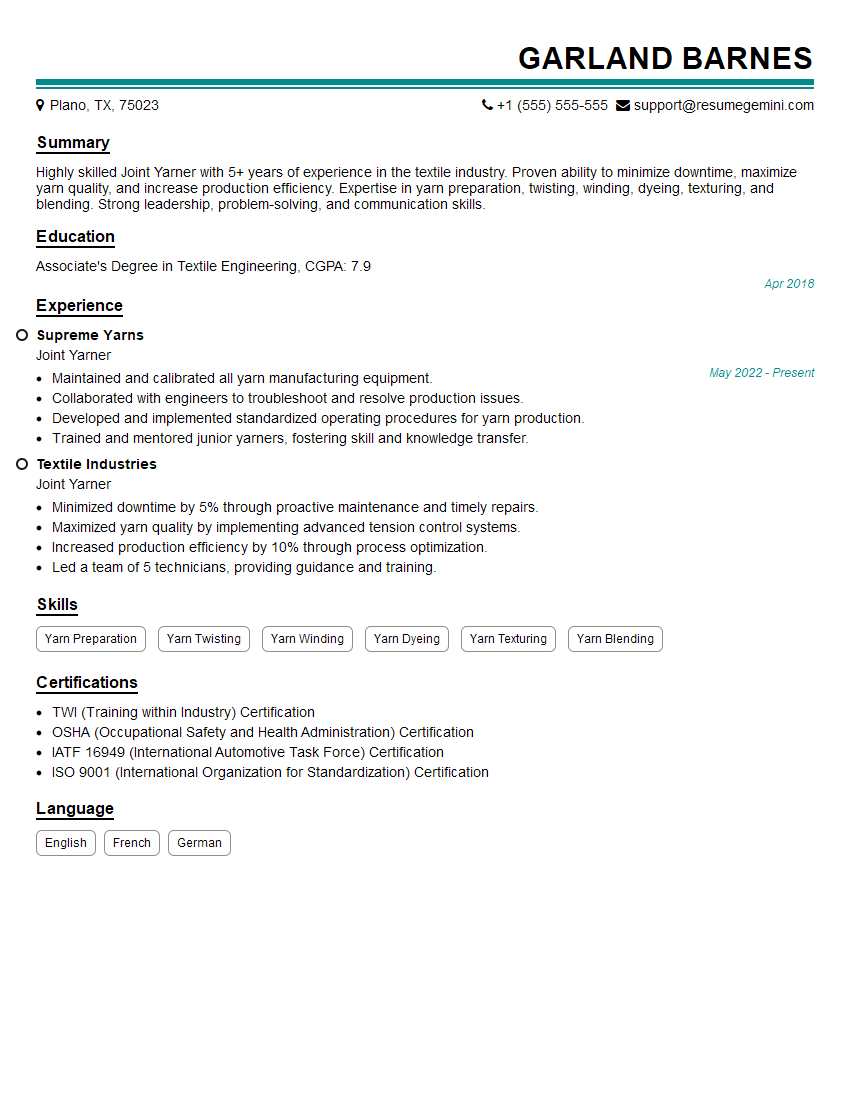

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Joint Yarner

1. What are the key steps involved in yarn jointing?

In yarn jointing, several crucial steps are involved, including:

- Preparing the yarn ends: This entails removing any imperfections or loose fibers from the yarn’s ends to ensure a clean and secure joint.

- Joining the yarn ends: Various methods can be employed to join the yarn ends, such as the weaver’s knot, the surgeon’s knot, or a mechanical yarn jointer.

- Securing the joint: After joining the yarn ends, it is essential to secure the joint by applying a binding agent or adhesive to reinforce the connection.

- Testing the joint: Once the joint is secured, it should be tested to ensure its strength and durability before putting it into operation.

2. Explain how to select the appropriate yarn jointing method for a given application.

Factors to consider:

- Yarn type and fiber content

- Yarn count and twist level

- Required joint strength

- End-use application and performance requirements

Common jointing methods:

- Weaver’s knot: Suitable for joining yarns of similar count and twist

- Surgeon’s knot: Stronger than the weaver’s knot, ideal for heavier yarns

- Mechanical yarn jointer: Provides a consistent and reliable joint for high-volume applications

3. Describe the different types of yarn jointing machines and their applications.

- Single-head yarn jointer: Used for joining individual yarn ends, suitable for small-scale operations

- Multi-head yarn jointer: Capable of joining multiple yarn ends simultaneously, increasing efficiency

- Automatic yarn jointer: Fully automated machines that offer high speed and precision, ideal for large-scale production

- Ultrasonic yarn jointer: Employs ultrasonic waves to create a strong and seamless joint, often used for synthetic fibers

4. How do you ensure the quality of yarn joints?

- Proper preparation and cleaning of yarn ends

- Selecting the appropriate jointing method and materials

- Following the manufacturer’s instructions for the jointing machine

- Regular maintenance and calibration of jointing machines

- Implementing quality control measures, such as visual inspection and strength testing

5. What are the common defects associated with yarn jointing and how can they be prevented?

- Weak joints: Caused by improper preparation, incorrect knotting technique, or insufficient securing

- Yarn breakage at the joint: Occurs due to excessive tension or damage to the yarn during jointing

- Knot slippage: Results from loose knots or improper binding

- Preventing defects: Proper training, attention to detail, and adherence to best practices

6. How do you handle yarn tension during jointing to minimize breakage?

- Using yarn tensioners or guides to maintain consistent tension throughout the jointing process

- Adjusting the settings of the jointing machine to accommodate the yarn type and count

- Avoiding excessive pulling or stretching of the yarn during knotting

- Inspecting the yarn for any weak spots or imperfections before jointing

7. What maintenance procedures are essential for yarn jointing machines?

- Regular cleaning and lubrication of all moving parts

- Checking and adjusting the tension settings periodically

- Calibrating the machine according to the manufacturer’s specifications

- Replacing worn or damaged parts promptly

- Following a preventive maintenance schedule to minimize downtime

8. How do you optimize the efficiency of a yarn jointing operation?

- Using the appropriate jointing method and machine for the specific application

- Streamlining the workflow and minimizing handling of the yarn

- Training operators on best practices and proper techniques

- Automating the jointing process whenever possible

- Monitoring and analyzing production data to identify areas for improvement

9. What are the safety precautions that should be observed when operating yarn jointing machines?

- Wearing appropriate safety gear, including gloves and eye protection

- Ensuring that the machine is properly grounded and regularly inspected

- Keeping the work area clean and free from tripping hazards

- Following lockout/tagout procedures before performing maintenance or repairs

- Being aware of potential hazards, such as moving parts and sharp edges

10. How do you stay updated with the latest advancements in yarn jointing technology?

- Attending industry conferences and exhibitions

- Reading trade publications and technical articles

- Consulting with experts and equipment manufacturers

- Participating in online forums and discussion groups

- Researching new products and technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Joint Yarner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Joint Yarner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Joint Yarner is responsible for operating a machine that joins yarns together to create a single, continuous thread. The primary goal is to ensure the efficient and accurate production of high-quality yarns. Key responsibilities include:

1. Machine Operation

Setting up and operating jointing machines to join different yarns

- Maintaining and calibrating machinery to ensure optimal performance

- Monitoring and adjusting tension and speed settings for precise yarn joining

2. Yarn Handling

Preparing and handling different types of yarns, including natural fibers (e.g., cotton, wool) and synthetic fibers (e.g., polyester, nylon)

- Ensuring proper yarn tension and alignment during the joining process

- Inspecting yarns for defects and making necessary adjustments to prevent breakage

3. Quality Control

Inspecting and testing joined yarns to ensure they meet quality standards

- Identifying and correcting any inconsistencies or defects in the yarn

- Maintaining accurate records of yarn properties and test results

4. Production Management

Monitoring production processes to ensure efficiency and minimize downtime

- Scheduling and coordinating yarn joining operations to meet production targets

- Identifying and resolving production bottlenecks and inefficiencies

Interview Tips

Preparing for an interview for a Joint Yarner position requires thorough research, practice, and a positive attitude. Here are some essential tips to help candidates ace the interview:

1. Research the Company and Role

Gather information about the company’s history, values, and products. Understand the specific requirements of the Joint Yarner role and how your skills and experience align with them.

- Review the company website, LinkedIn profile, and industry publications.

- Identify keywords in the job description and tailor your resume and cover letter accordingly.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating jointing machines, yarn handling, and quality control techniques.

- Quantify your accomplishments and use specific examples to demonstrate your skills.

- Prepare to discuss your knowledge of different yarn types and their properties.

3. Demonstrate Your Attention to Detail

Joint Yarners need to be meticulous and have a keen eye for detail. Highlight your ability to identify and correct even minor inconsistencies in yarn quality.

- Provide examples of how you have identified and resolved yarn defects in previous roles.

- Explain how you maintain accurate records and ensure compliance with quality standards.

4. Emphasize Your Production Management Skills

Show that you understand the importance of efficiency and productivity in a manufacturing environment.

- Describe your experience in scheduling and coordinating yarn joining operations.

- Explain how you have identified and resolved production bottlenecks in the past.

5. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- “Tell me about your experience in operating jointing machines.”

- “How do you ensure the quality of joined yarns?”

- “What are your strategies for maximizing production efficiency?”

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. Be polite and respectful to everyone you encounter.

7. Be Enthusiastic and Confident

Show your enthusiasm for the role and the company. Maintain a positive attitude and project confidence in your abilities.

- Highlight your passion for the textile industry and your commitment to producing high-quality yarns.

- Express your willingness to learn and contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Joint Yarner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!