Are you gearing up for an interview for a Jointer Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Jointer Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

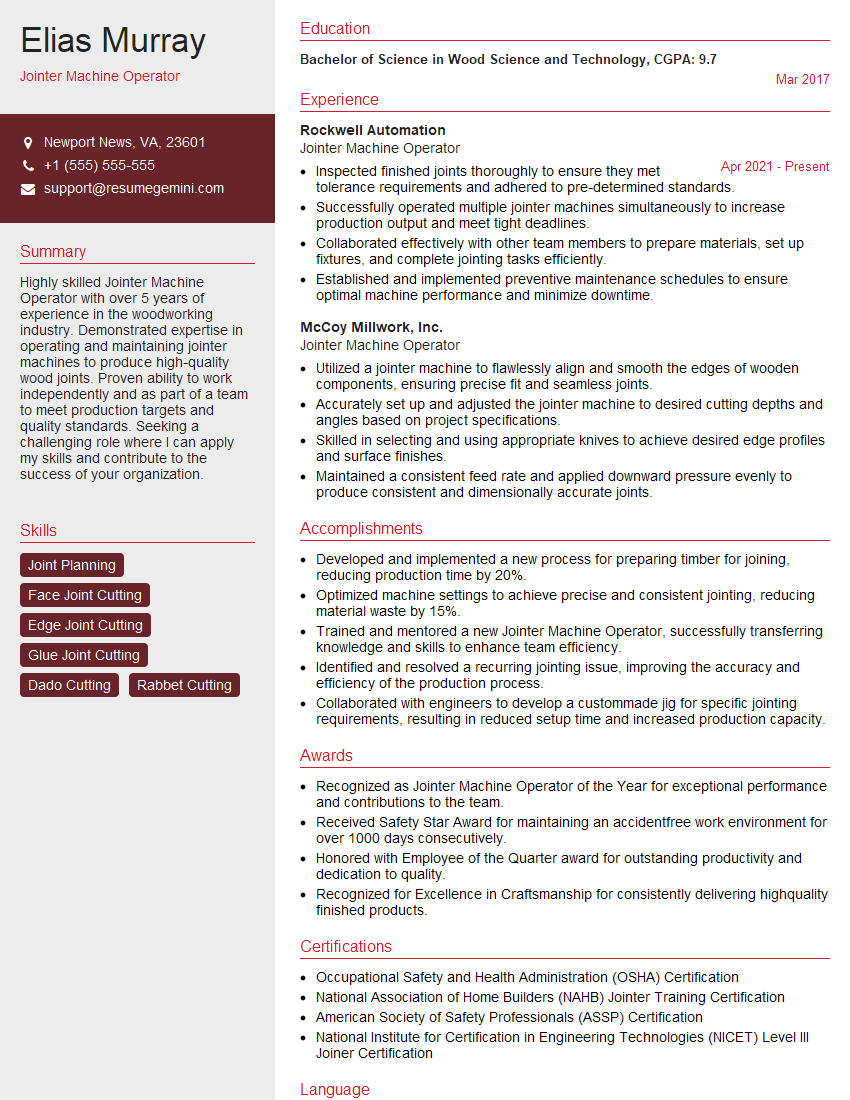

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Jointer Machine Operator

1. What are the steps involved in operating a jointer machine safely?

The steps involved in operating a jointer machine safely:

- Wear proper safety gear, including eye protection, ear protection, and gloves.

- Inspect the jointer machine before each use to make sure it is in good working order.

- Set up the machine according to the manufacturer’s instructions.

- Secure the workpiece to the jointer table.

- Power on the machine and let it reach its full speed.

- Feed the workpiece into the jointer slowly and evenly.

- Keep your hands away from the cutter head.

- Stop the machine and unplug it before making any adjustments.

- Never leave the machine running unattended.

2. What are the different types of jointer machines?

Benchtop jointers:

- Benchtop jointers are the smallest and most portable type of jointer.

- They are ideal for small workshops or for occasional use.

Floor-standing jointers:

- Floor-standing jointers are larger and more powerful than benchtop jointers.

- They are ideal for larger workshops or for more frequent use.

Wide-belt jointers:

- Wide-belt jointers are the largest and most powerful type of jointer.

- They are used for high-volume production work.

3. What are the different types of jointer cutters?

The different types of jointer cutters include:

- Straight cutters: Straight cutters are used to create a flat surface.

- Bevel cutters: Bevel cutters are used to create a beveled edge.

- Rabbet cutters: Rabbet cutters are used to create a rabbet joint.

- Dado cutters: Dado cutters are used to create a dado joint.

4. How do you set up a jointer machine?

To set up a jointer machine, you will need to:

- Place the machine on a level surface.

- Install the appropriate cutter head.

- Adjust the fence to the desired width.

- Adjust the table height to the desired thickness.

- Power on the machine and let it reach its full speed.

5. How do you maintain a jointer machine?

To maintain a jointer machine, you should:

- Clean the machine regularly.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for any signs of damage.

- Have the machine serviced by a qualified technician on a regular basis.

6. What are the common problems that can occur with a jointer machine?

The common problems that can occur with a jointer machine include:

- Clogged cutter head: A clogged cutter head can cause the machine to jam.

- Misaligned fence: A misaligned fence can cause the workpiece to be cut unevenly.

- Worn bearings: Worn bearings can cause the machine to vibrate excessively.

- Damaged cutter head: A damaged cutter head can cause the machine to produce uneven cuts.

7. How do you troubleshoot a jointer machine?

To troubleshoot a jointer machine, you should:

- Check for any obvious problems, such as a clogged cutter head or a misaligned fence.

- If there are no obvious problems, then you should consult the machine’s manual for troubleshooting tips.

- If you are unable to resolve the problem, then you should contact a qualified technician.

8. What are the safety precautions that must be taken when operating a jointer machine?

The safety precautions that must be taken when operating a jointer machine include:

- Wear proper safety gear, including eye protection, ear protection, and gloves.

- Inspect the machine before each use to make sure it is in good working order.

- Set up the machine according to the manufacturer’s instructions.

- Secure the workpiece to the jointer table.

- Power on the machine and let it reach its full speed.

- Feed the workpiece into the jointer slowly and evenly.

- Keep your hands away from the cutter head.

- Stop the machine and unplug it before making any adjustments.

- Never leave the machine running unattended.

9. What are the different types of joints that can be made with a jointer machine?

The different types of joints that can be made with a jointer machine include:

- Butt joint: A butt joint is the simplest type of joint, and it is made by joining two pieces of wood together end-to-end.

- Edge joint: An edge joint is made by joining two pieces of wood together along their edges.

- Miter joint: A miter joint is made by joining two pieces of wood together at a 45-degree angle.

- Dado joint: A dado joint is made by cutting a groove into one piece of wood and then inserting another piece of wood into the groove.

- Rabbet joint: A rabbet joint is made by cutting a recess into one piece of wood and then inserting another piece of wood into the recess.

10. How do you adjust the fence and table on a jointer machine?

To adjust the fence on a jointer machine, you will need to:

- Loosen the fence lock knob.

- Slide the fence to the desired position.

- Tighten the fence lock knob.

To adjust the table on a jointer machine, you will need to:

- Loosen the table lock knob.

- Tilt the table to the desired angle.

- Tighten the table lock knob.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Jointer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Jointer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Jointer Machine Operator plays a critical role in maintaining the accuracy and efficiency of manufacturing processes. Their primary responsibilities include:

1. Machine Operation

Operate Jointer machine to produce straight, smooth, and even surfaces on wooden boards or edges

- Set up and adjust Jointer machine according to job specifications

- Monitor machine operation and make necessary adjustments to maintain production quality

2. Material Preparation

Select and inspect wooden boards to ensure they are suitable for jointing

- Measure and mark boards for precise jointing

- Feed boards into Jointer machine with proper alignment

3. Quality Control

Inspect finished products to ensure they meet quality standards

- Identify and correct any defects or imperfections

- Maintain accurate records of jointing operations and quality control checks

4. Maintenance

Perform basic maintenance on Jointer machine to ensure optimal performance

- Clean and lubricate machine components

- Identify and report any maintenance issues to supervisor

Interview Tips

To ace the interview for a Jointer Machine Operator position, consider the following tips:

1. Research the Company

Familiarize yourself with the company’s industry, products, and work culture. This shows the interviewer that you are interested in the role and the company itself.

- Visit the company website and LinkedIn page

- Read industry-related news and articles

2. Highlight Experience

Emphasize your previous experience operating Jointer machines or similar woodworking equipment. Showcase your ability to maintain quality standards and troubleshoot issues.

- Provide specific examples of your accomplishments and quantify your results

- Explain how your experience aligns with the job responsibilities outlined in the description

3. Demonstrate Attention to Detail

Jointer Machine Operators are required to work with precision and attention to detail. During the interview, highlight your ability to focus on accuracy and identify and correct errors.

- Describe your quality control procedures and how you ensure the accuracy of your work

- Provide examples of when you identified and rectified mistakes

4. Prepare Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the job or the company.

- Ask about the company’s safety protocols and training programs

- Inquire about growth opportunities within the organization

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Jointer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!