Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Journeyman Machinist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Journeyman Machinist so you can tailor your answers to impress potential employers.

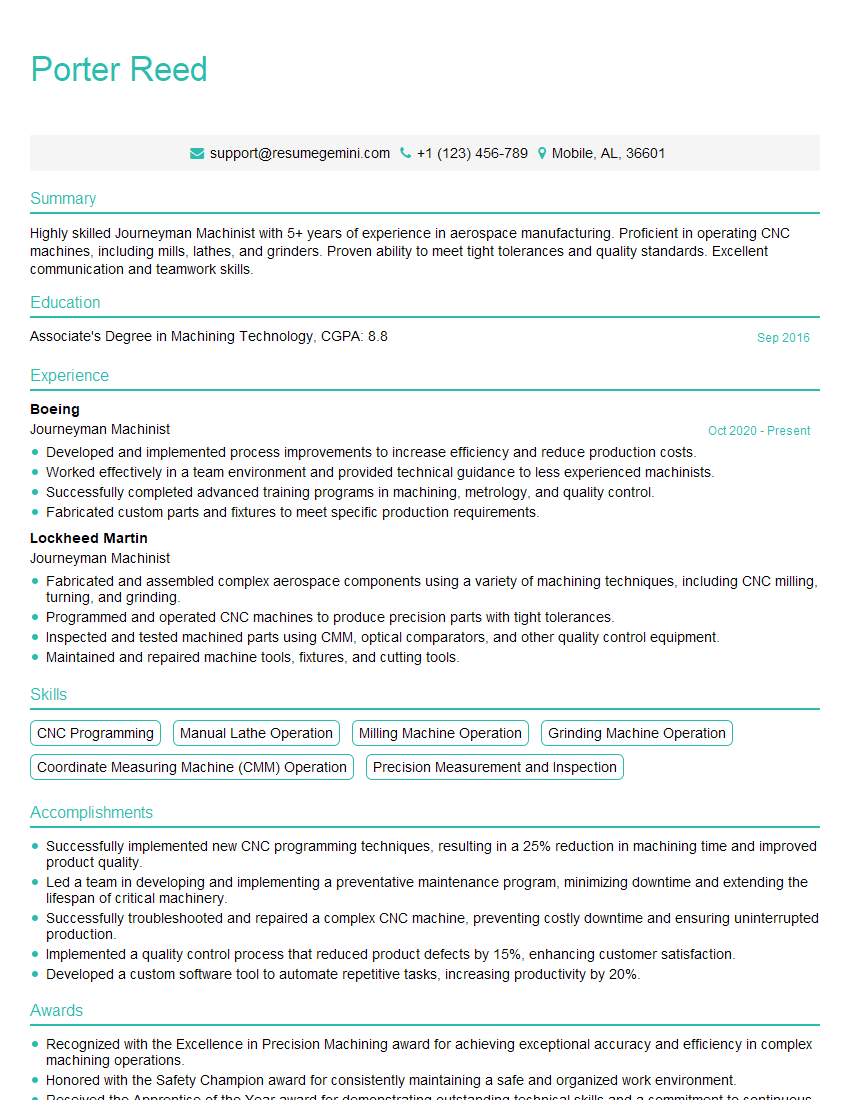

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Journeyman Machinist

1. What are the different types of milling machines and their applications?

- Knee mill: Uses a movable table that can be positioned in three axes (X, Y, and Z) for precise milling of small to medium-sized parts or components.

- Bed mill: Similar to a knee mill, but has a larger work table and is designed for heavier duty applications, such as milling large castings or structural components.

- Vertical mill: The spindle is mounted vertically and the table moves in the X and Y axes, allowing for precise machining of surfaces perpendicular to the spindle axis, such as profiling or engraving.

- Horizontal mill: The spindle is mounted horizontally and the workpiece is typically held on a rotary table, allowing for precise milling of surfaces parallel to the spindle axis, such as cutting keyways or slots.

- CNC mill: A computer-controlled milling machine that uses numerical control (NC) to automate the movement of the table and spindle, enabling precise and complex machining operations.

2. Describe the process of heat treating steel and its effects on the material’s properties.

subheading of the answer

- Annealing: Slow heating and cooling, which softens the steel and reduces its hardness.

- Normalizing: Heating to a higher temperature than annealing and cooling in still air, which produces a finer grain structure and improved toughness.

subheading of the answer

- Hardening: Rapid cooling from a high temperature, which increases the steel’s hardness but also makes it more brittle.

- Tempering: Heating hardened steel to a lower temperature and cooling slowly, which reduces brittleness and improves toughness while maintaining hardness.

3. What are the different types of surface finishes and how are they achieved?

- Rough surface: Achieved by using coarse abrasives or machining tools, with a high Ra value (roughness average).

- Smooth surface: Achieved by using finer abrasives or precision machining, with a lower Ra value.

- Polished surface: Achieved by using very fine abrasives or polishing compounds, with a near-mirror finish.

- Honed surface: Achieved by using fine abrasives with a back-and-forth motion, resulting in a very smooth and precise finish.

4. What are the common types of cutting tools used in machining and their applications?

- Single-point cutting tools: Used for turning, facing, boring, and threading operations, such as lathe tools and boring bars.

- Multi-point cutting tools: Used for milling, drilling, and tapping operations, such as milling cutters, drill bits, and taps.

- Abrasive cutting tools: Used for grinding and cutting hard materials, such as grinding wheels, cutoff wheels, and honing stones.

5. What are the factors that affect the accuracy and precision of a machining process?

- Machine tool quality: Precision and accuracy of the machine tool, including its rigidity, backlash, and spindle runout.

- Cutting tool quality: Sharpness, geometry, and material of the cutting tool.

- Workpiece material: Hardness, toughness, and machinability of the workpiece material.

- Machining parameters: Cutting speed, feed rate, and depth of cut.

- Environmental factors: Temperature, humidity, and vibration.

6. What are the different types of measuring tools and instruments used in machining and their applications?

- Vernier calipers: Used for precise measurement of linear dimensions, such as internal and external diameters.

- Micrometers: Used for extremely precise measurement of linear dimensions, such as the thickness of a workpiece or the diameter of a hole.

- Dial indicators: Used for measuring small displacements or variations, such as the runout of a spindle or the flatness of a surface.

- Coordinate measuring machine (CMM): Used for precise measurement of complex geometries and dimensions, such as those found in automotive or aerospace components.

7. What are the common types of quality control procedures used in machining and their importance?

- Dimensional inspection: Verifying the accuracy and precision of machined parts using measuring tools and instruments.

- Surface inspection: Checking for surface defects such as scratches, burrs, or irregularities using visual inspection or surface roughness measurements.

- Material testing: Verifying the material properties of the workpiece, such as hardness, tensile strength, or chemical composition.

- Functional testing: Testing the functionality and performance of machined parts under actual or simulated operating conditions.

8. What are the different types of maintenance and troubleshooting techniques used in machining operations?

- Preventive maintenance: Regular inspections, cleaning, lubrication, and adjustments to prevent breakdowns and extend the life of the equipment.

- Predictive maintenance: Using sensors and monitoring systems to identify potential problems before they occur, allowing for timely intervention and repairs.

- Corrective maintenance: Troubleshooting and repairing equipment failures or malfunctions to restore functionality.

9. What are the safety precautions that should be taken when operating machining equipment?

- Wear appropriate personal protective equipment (PPE): Safety glasses, gloves, earplugs, and protective clothing.

- Follow proper machine operating procedures: Read and understand the machine manual, and always follow the recommended safety guidelines.

- Inspect equipment before use: Ensure that the machine is in good working condition and that all safety guards are in place.

- Keep the work area clean and organized: Remove scrap material, debris, and tools from the work area to prevent tripping or falling hazards.

- Be aware of potential hazards: Be alert to moving parts, rotating spindles, and sharp cutting tools, and keep a safe distance from these areas.

10. What are your strengths and weaknesses as a Journeyman Machinist?

- Strengths:

- Strong technical skills in machining operations, including milling, turning, drilling, and grinding.

- Proficient in reading and interpreting engineering drawings.

- Excellent understanding of machining principles, materials, and cutting tools.

- Ability to work independently and as part of a team.

- Weaknesses:

- Limited experience in advanced machining techniques such as CNC programming.

- Still working on improving my efficiency in setting up and operating complex machining equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Journeyman Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Journeyman Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Journeyman Machinists are highly skilled professionals responsible for operating and maintaining complex machinery and equipment used in various industries. Their key job responsibilities include:

1. Machine Operation

Operate a variety of machining equipment, such as lathes, mills, grinders, and CNC machines, to produce precision parts and components.

2. Job Setup and Planning

Read and interpret blueprints and specifications to determine the appropriate tooling, setup, and machining parameters.

3. Part Inspection and Quality Control

Inspect machined parts and components to ensure they meet specified tolerances and quality standards.

4. Machine Maintenance and Repair

Perform routine maintenance and repairs on machinery and equipment to ensure optimal performance.

5. Tooling and Equipment Selection

Select and use the appropriate tooling and equipment for specific machining operations.

6. Training and Supervision

May be responsible for training and supervising apprentices or other machinists.

Interview Tips

Preparing thoroughly for a Journeyman Machinist interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company you’re applying to, their industry, and the specific job requirements. This knowledge will help you tailor your answers and demonstrate your understanding of the role.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience in machining operations, part inspection, and machine maintenance. Quantify your accomplishments with specific examples whenever possible.

3. Be Prepared for Technical Questions

Expect technical questions related to machining processes, equipment, and materials. Review your knowledge and prepare responses that demonstrate your proficiency.

4. Showcase Your Problem-Solving Abilities

Journeyman Machinists often encounter challenges in their work. Prepare to discuss how you approach problem-solving, identify root causes, and develop effective solutions.

5. Ask Thoughtful Questions

Ask insightful questions during the interview to show your interest in the company, the position, and the industry. This also allows you to gather additional information to help you make an informed decision.

Next Step:

Now that you’re armed with the knowledge of Journeyman Machinist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Journeyman Machinist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini