Are you gearing up for an interview for a Journeyman Pipe Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Journeyman Pipe Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

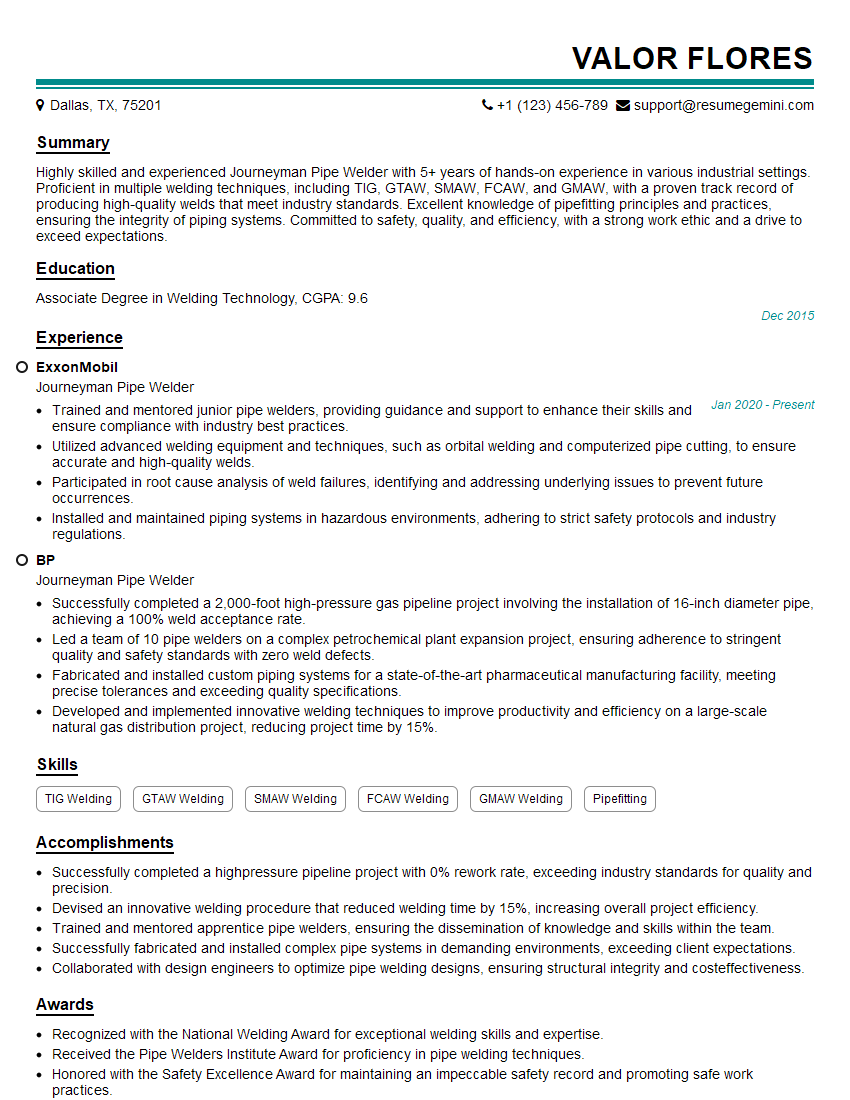

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Journeyman Pipe Welder

1. What are the different welding processes you are proficient in?

As a Journeyman Pipe Welder, I am proficient in various welding processes, including:

- Shielded metal arc welding (SMAW)

- Gas tungsten arc welding (GTAW)

- Gas metal arc welding (GMAW)

- Flux-cored arc welding (FCAW)

- Submerged arc welding (SAW)

2. How do you ensure the quality of your welds?

Inspection and Testing

- Visually inspect welds for defects, such as cracks, slag inclusions, and undercuts.

- Perform non-destructive testing (NDT) methods, such as radiography, ultrasonic testing, and magnetic particle testing, to detect internal weld defects.

Compliance with Standards

- Strictly adhere to welding codes and standards, such as ASME B31.3 and AWS D1.1.

- Ensure welds meet the specified weld joint design, penetration, and strength requirements.

3. What is your experience with welding different types of materials?

I have extensive experience welding a wide range of materials, including:

- Carbon steel

- Alloy steel

- Stainless steel

- Aluminum

- Copper and copper alloys

4. What are the safety precautions you observe while welding?

- Wear appropriate personal protective equipment (PPE), including welding helmet, gloves, and protective clothing.

- Ensure a well-ventilated workspace and use proper ventilation equipment to prevent inhalation of harmful fumes.

- Inspect welding equipment regularly to ensure its safety and proper functioning.

- Follow established safety protocols and procedures, including proper handling, storage, and disposal of welding materials.

5. How do you handle welding in challenging environments, such as confined spaces or at heights?

- Assess the work area thoroughly to identify potential hazards and develop appropriate safety plans.

- Use specialized equipment and techniques, such as welding platforms, fall protection systems, and remote welding tools.

- Ensure clear communication and coordination with coworkers to maintain safety and efficiency.

- Prioritize safety without compromising the quality of the welds.

6. What is your preferred welding position, and why?

My preferred welding position is [position], as it allows me to maintain:

- Optimal control over the welding torch and arc manipulation.

- Good visibility of the weld joint and the weld pool.

- Comfortable and ergonomic posture, reducing fatigue and improving welding accuracy.

7. How do you stay updated on the latest welding technologies and best practices?

- Attend industry conferences and workshops to learn about new techniques and advancements.

- Read technical journals, articles, and textbooks to stay informed about industry developments.

- Participate in online forums and discussion groups to connect with fellow welders and share knowledge.

- Seek opportunities to work with experienced mentors and supervisors who stay abreast of the latest welding trends.

8. What is the most complex welding project you have worked on?

The most complex welding project I have worked on involved:

- Welding high-pressure piping systems in a critical industrial facility.

- Working in confined spaces with limited access and visibility.

- Using specialized welding techniques, such as orbital welding, to ensure precision and reliability.

- Meeting stringent quality control standards and adhering to tight deadlines.

9. How do you troubleshoot welding problems and ensure timely project completion?

- Analyze weld defects and identify potential causes, such as incorrect welding parameters, equipment malfunctions, or material issues.

- Implement corrective actions based on the identified root causes, such as adjusting welding settings, replacing faulty parts, or using alternative welding materials.

- Continuously monitor welding progress and make necessary adjustments to maintain productivity and quality.

- Communicate with supervisors, engineers, and other stakeholders to keep them informed of potential delays and any corrective measures taken.

10. How do you contribute to maintaining a safe and efficient work environment?

- Follow established safety protocols and procedures to prevent accidents and injuries.

- Maintain a clean and organized work area to minimize tripping hazards and facilitate efficient workflow.

- Identify and report any potential safety concerns or equipment malfunctions immediately.

- Collaborate with coworkers to promote teamwork and a positive work atmosphere.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Journeyman Pipe Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Journeyman Pipe Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Journeyman Pipe Welders are highly skilled professionals who play a significant role in the construction, maintenance, and repair of pipelines and piping systems. Their responsibilities encompass a wide range of tasks, including:

1. Welding and Joining Pipes

Journeyman Pipe Welders are responsible for welding and joining pipes of various sizes and materials, ensuring the integrity and strength of the joints. They use specialized welding techniques, including stick welding, gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW), to create strong and durable bonds.

2. Fabrication and Installation

They are often involved in the fabrication and installation of piping systems, working closely with other tradespeople to ensure proper alignment, support, and connection of pipes and fittings.

3. Inspection and Maintenance

Journeyman Pipe Welders are responsible for inspecting and maintaining piping systems, identifying potential issues and performing necessary repairs or replacements. They use specialized tools and techniques to diagnose problems and ensure the safe and efficient operation of the system.

4. Code Compliance and Documentation

They must adhere to strict codes and regulations while performing welding and installation tasks. They are also responsible for maintaining accurate documentation of their work, including welding procedures, inspection reports, and maintenance records.

Interview Tips

Preparing for a Journeyman Pipe Welder interview can help you showcase your skills and experience, and increase your chances of success.

1. Research the Company and Position

Research the company and the specific position you are applying for. This will give you a good understanding of the company’s culture, values, and the specific requirements of the role.

- Look through the company website, social media pages, and industry news to gather information on their operations and reputation.

- Read the job description carefully and identify the key responsibilities and requirements. Highlight your skills and experience that align with these requirements.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your relevant skills and experience.

- Describe your experience in welding and joining pipes using different techniques.

- Share an example of a complex welding project you have completed and the challenges you faced.

- Explain your knowledge of welding codes and standards, and provide examples of how you have applied them in your work.

- Discuss your experience in inspecting and maintaining piping systems, and how you ensure the safety and integrity of these systems.

3. Showcase Your Technical Skills

Highlight your technical skills and knowledge of welding techniques, equipment, and materials.

- Bring examples of your work, such as welding samples or project documentation, to demonstrate your skills.

- Be prepared to discuss your experience with different types of welding equipment, such as stick welders, GTAW machines, and GMAW equipment.

- Explain your understanding of welding processes, including the different types of welding joints and the factors that affect weld quality.

4. Emphasize Safety and Quality

In a Journeyman Pipe Welder role, safety and quality are paramount. Emphasize your commitment to these aspects in your interview.

- Explain your understanding of welding safety protocols and how you ensure your work meets industry standards.

- Provide examples of how you have identified and resolved potential safety hazards on the job.

- Describe your quality control processes and how you ensure the integrity and reliability of your welds.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Journeyman Pipe Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.