Are you gearing up for a career in Journeyman Tool and Die Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Journeyman Tool and Die Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

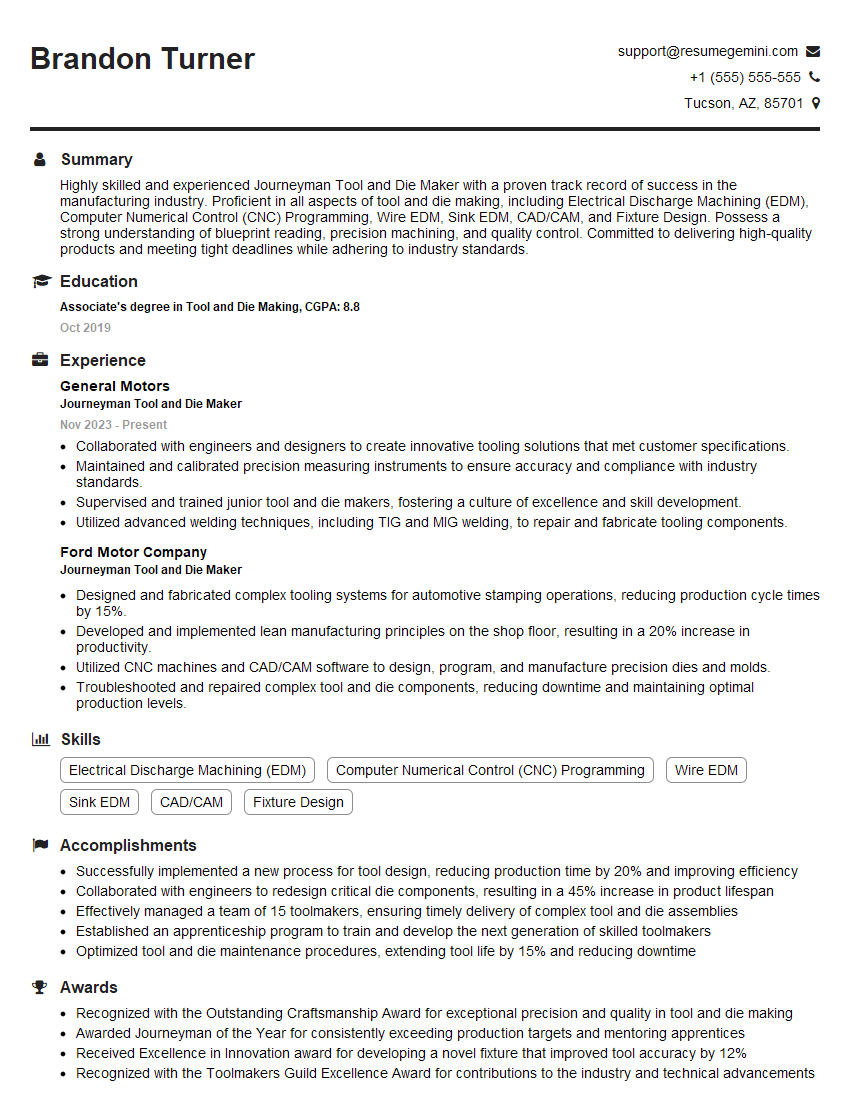

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Journeyman Tool and Die Maker

1. Describe your experience in using CMM (Coordinate Measuring Machine)?

- Explain the types of CMMs you have worked with (e.g., gantry, bridge, portable).

- Describe your proficiency in operating CMM software and performing measurements.

- Mention any specific CMM inspection techniques you are familiar with (e.g., touch-trigger probing, laser scanning).

2. How do you ensure the accuracy and repeatability of your measurements?

Calibration and Verification

- Explain the importance of regularly calibrating and verifying CMM equipment.

- Describe the calibration procedures you follow and the frequency of calibration.

Measurement Techniques

- Discuss the impact of probing techniques, stylus selection, and measurement algorithms on accuracy.

- Explain how you minimize measurement errors and ensure consistent results.

3. How do you approach the design and development of complex tooling and fixtures?

- Explain your process for understanding customer requirements and specifications.

- Describe the software tools and techniques you use for design and simulation.

- Discuss your experience in working with engineers and design teams.

4. Can you walk me through the process of designing a progressive die for a sheet metal component?

- Explain the key stages involved in progressive die design, from concept to production.

- Describe the considerations for material selection, tooling design, and part flow.

- Discuss any specific software or techniques you use for progressive die design.

5. What are the common materials used in tool and die making, and how do their properties affect the design process?

- List the different types of steels and alloys used in tool and die making.

- Explain the properties of each material, such as hardness, toughness, and wear resistance.

- Discuss how material selection impacts the design and manufacturing process.

6. Describe your experience in using wire EDM (Electrical Discharge Machining) for tool and die fabrication.

- Explain the different types of wire EDM machines you have used.

- Describe the process parameters you optimize for efficient and accurate cutting.

- Discuss how you ensure the precision and surface finish required for tool and die components.

7. How do you maintain and troubleshoot tool and die equipment to minimize downtime?

- Explain your approach to preventive maintenance and regular inspections.

- Describe the troubleshooting techniques you use to identify and resolve equipment issues.

- Discuss your experience in working with maintenance teams and vendors.

8. What quality control procedures do you implement to ensure the accuracy and durability of your tools and dies?

- Explain the inspection methods you use, such as CMM measurements and surface roughness testing.

- Describe how you document and track quality control results.

- Discuss your understanding of quality standards and how you meet customer requirements.

9. How do you stay updated with the latest advancements and best practices in tool and die making?

- Describe the industry magazines, conferences, and training programs you attend.

- Explain how you leverage online resources and research to expand your knowledge.

- Discuss your involvement in professional organizations or technical committees.

10. What sets you apart from other candidates for this role as a Journeyman Tool and Die Maker?

- Highlight your unique skills, experience, and qualifications that align with the job requirements.

- Explain how your passion for tool and die making drives your commitment to excellence.

- Express your enthusiasm for the opportunity to contribute to the success of the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Journeyman Tool and Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Journeyman Tool and Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Journeyman Tool and Die Makers possess a comprehensive understanding of tool and die making principles and practices. They are highly competent in the planning, development, fabrication, and maintenance of tools, dies, jigs, and fixtures utilized in various manufacturing processes.

1. Tool and Die Design

Analyze product blueprints, specifications, and design requirements to comprehend the intended functionality of tools and dies.

- Develop detailed design plans and sketches for new or modified tooling.

- Apply knowledge of materials, geometry, and manufacturing principles to optimize tool and die performance.

2. Tool and Die Fabrication

Utilize a wide range of precision machining equipment, such as lathes, mills, and grinders, to fabricate tool and die components.

- Select and use appropriate cutting tools and techniques to achieve the required tolerances and finishes.

- Follow quality control procedures to ensure that fabricated components meet specifications.

3. Tool and Die Assembly

Assemble individual tool and die components into complete units.

- Adjust and calibrate tools and dies to ensure proper operation and functionality.

- Inspect assembled tooling to verify that it meets design specifications and performance requirements.

4. Tool and Die Maintenance and Repair

Conduct routine maintenance and repairs on tools and dies to ensure optimal performance.

- Troubleshoot and diagnose tool and die failures to identify and resolve issues promptly.

- Overhaul and rebuild tools and dies as necessary to extend their service life.

Interview Tips

To excel in a Journeyman Tool and Die Maker interview, it is essential to demonstrate a deep understanding of the job responsibilities and possess the necessary technical skills and experience. Here are some tips to help you prepare and ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s mission, values, and industry standing. Understand the specific requirements of the Journeyman Tool and Die Maker position and how your skills and experience align with them.

2. Highlight Your Technical Expertise

Emphasize your proficiency in tool and die design, fabrication, assembly, and maintenance. Provide specific examples of projects you have worked on that showcase your abilities in each area.

3. Demonstrate Your Problem-Solving Skills

Tool and Die Makers are often tasked with resolving complex manufacturing issues. Highlight your analytical and troubleshooting abilities, and provide examples of how you have successfully identified and solved problems in previous roles.

4. Showcase Your Attention to Detail

Journeyman Tool and Die Makers must be meticulous and detail-oriented to ensure the accuracy and precision of their work. Emphasize your commitment to quality and your ability to work within tight tolerances.

5. Prepare for Common Interview Questions

Anticipate questions related to your technical skills, experience with specific tools and materials, and your approach to problem-solving. Practice answering these questions clearly and concisely.

Next Step:

Now that you’re armed with the knowledge of Journeyman Tool and Die Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Journeyman Tool and Die Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini