Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Juice Weigher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

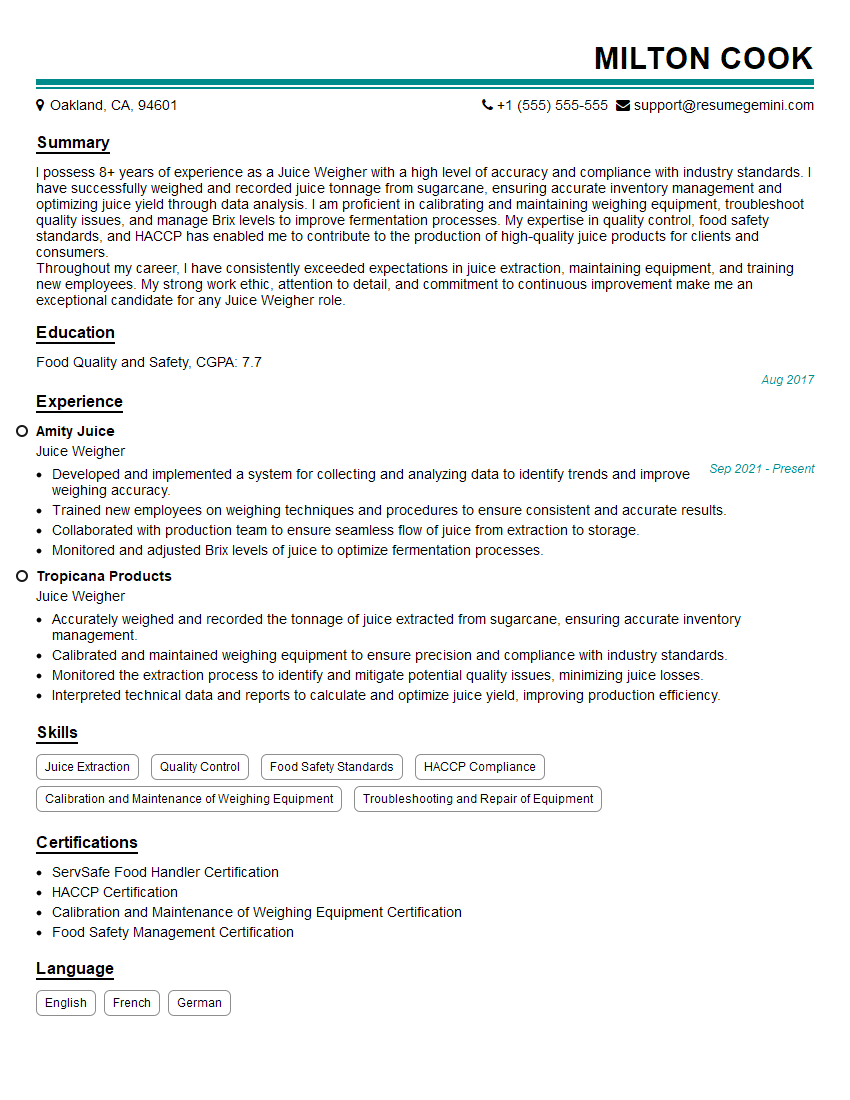

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Juice Weigher

1. How do you ensure the accuracy of the weighing scales?

To ensure the accuracy of the weighing scales, I regularly perform the following procedures:

- Tare adjustment: I make sure to zero out the scale before each weighing by pressing the tare button.

- Calibration: I calibrate the scale periodically using certified calibration weights to ensure it meets the required accuracy specifications.

- Routine inspection: I inspect the scale’s components, such as the weighing platter, load cell, and display, for any damage or wear that could affect its accuracy.

2. What types of scales are commonly used for weighing juice?

Weighbridge Scales

- Used for weighing large quantities of juice in bulk

- Provide highly accurate measurements

Electronic Scales

- Compact and portable for weighing smaller amounts of juice

- Offer precise measurements and digital readouts

Hydrometers

- Used for determining the specific gravity of juice to estimate its Brix content

- Simple and inexpensive method

3. What is the importance of weighing juice accurately?

- Ensures accurate blending and recipe formulation

- Prevents overfilling or underfilling of containers

- Assists in inventory management and cost control

- Maintains product quality and consistency

- Complies with regulatory requirements and standards

4. How do you handle discrepancies between the readings of different scales?

- Verify the condition of the scales: I ensure that all scales involved are clean, calibrated, and functioning correctly.

- Re-weigh the juice: I weigh the same sample of juice on both scales to confirm the discrepancy.

- Compare results: I analyze the differences in the readings to determine which scale is providing more accurate results.

- Resolve the issue: I recalibrate or adjust the scales as necessary to ensure consistency.

5. What safety precautions do you take when working with juice?

- Wear appropriate protective gear: I use gloves, aprons, and safety glasses to prevent spills and splashes.

- Maintain a clean work area: I keep the weighing area clean and free of debris to prevent contamination.

- Handle containers carefully: I lift and move containers of juice safely to avoid spills and injuries.

- Be aware of potential hazards: I am aware of the potential for slips and falls due to spills and take necessary precautions.

6. How do you ensure the traceability of juice weights?

- Maintain records: I keep detailed records of all weighing operations, including the date, time, scale used, and weight recorded.

- Use unique identifiers: I label containers with unique identifiers to track them throughout the weighing process.

- Implement quality control procedures: I regularly review weighing records and implement quality control checks to ensure accuracy and consistency.

7. What do you do to maintain the cleanliness and sanitation of the weighing equipment?

- Regular cleaning: I clean the scales and other equipment regularly using approved cleaning agents and sanitizers.

- Disinfection: I disinfect the equipment after each use to prevent the spread of bacteria.

- Inspection: I inspect the equipment regularly for any signs of contamination or damage.

8. How do you calibrate the weighing scales?

- Use certified calibration weights: I use certified calibration weights of known accuracy to calibrate the scales.

- Follow manufacturer’s instructions: I carefully follow the manufacturer’s instructions for calibration.

- Record calibration data: I record the date, time, and results of each calibration for traceability.

9. What are the different methods for weighing juice?

- Manual weighing: Using a manual scale to weigh the juice directly.

- Automated weighing: Using automated weighing systems that integrate with production lines.

- In-line weighing: Weighing juice as it flows through a production line using load cells.

10. How do you handle spills or leaks of juice during weighing?

- Clean up spills immediately: I promptly clean up any spills or leaks to prevent contamination and slipping hazards.

- Use absorbent materials: I use absorbent materials such as towels or spill kits to soak up spills.

- Report spills to supervisor: I report any significant spills or leaks to my supervisor for further action.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Juice Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Juice Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Juice Weighers play a vital role in the food and beverage industry, ensuring precise measurement and control of juice quantity. Their responsibilities encompass various aspects of juice production and packaging.

1. Weighing and Measuring Juice

Juice Weighers are entrusted with the accurate weighing and measuring of juice at various stages of production. They use calibrated scales, weighbridge, and other measuring devices to determine the weight and volume of juice.

2. Maintaining Equipment

To ensure accuracy and efficiency, Juice Weighers are responsible for the regular maintenance and calibration of weighing equipment. They perform routine checks, clean and lubricate components, and promptly report any issues to maintain optimal performance.

3. Monitoring Production

Juice Weighers vigilantly monitor the juicing process to ensure that the correct weight and quantity of juice are produced. They track production data, identify deviations from specifications, and take corrective actions as needed.

4. Documentation and Recordkeeping

Accurate documentation is crucial in the food and beverage industry. Juice Weighers meticulously maintain production records, recording weights, measurements, and other relevant data. These records provide traceability and facilitate compliance with industry regulations.

Interview Tips

A successful interview hinges on preparation and a clear understanding of the key responsibilities of a Juice Weigher. Here are some valuable tips to help you ace the interview:

1. Research the Industry and Position

Take the time to research the juice industry, the company you’re applying to, and the specific role of a Juice Weigher. This knowledge will demonstrate your interest and enable you to provide informed answers.

2. Highlight Relevant Experience and Skills

Emphasize your experience in weighing, measuring, and maintaining equipment. Showcase your proficiency in handling scales and weighbridge, as well as your understanding of calibration procedures.

3. Quantify Your Accomplishments

Use specific examples and quantifiable metrics to demonstrate your accomplishments in previous roles. This will provide tangible evidence of your contributions and impact.

4. Prepare Questions

Asking well-thought-out questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s production process, quality control measures, and opportunities for professional growth.

5. Dress Professionally and Be Punctual

First impressions matter. Dress professionally and arrive at the interview on time. This conveys respect and attention to detail, which are essential qualities for a Juice Weigher.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Juice Weigher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Juice Weigher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.