Are you gearing up for a career in Kerfer Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Kerfer Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

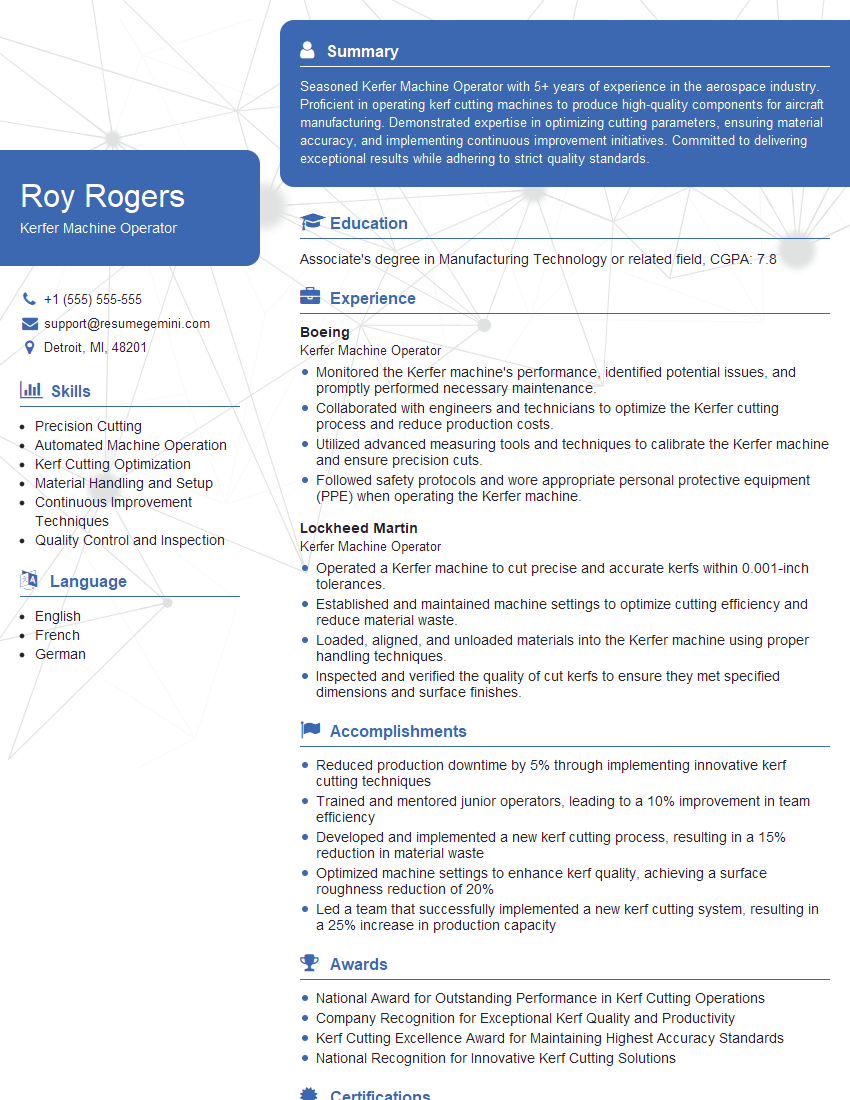

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kerfer Machine Operator

1. What are the key responsibilities of a Kerfer Machine Operator?

- Operate kerfer machine to cut boards to required length

- Set up and adjust machine to achieve optimal performance

- Inspect cut boards for defects and ensure they meet specifications

- Perform basic maintenance and troubleshooting on kerfer machine

- Follow safety guidelines and wear appropriate PPE

2. What are the different types of kerf cuts and their applications?

Types of kerf cuts

- Through-kerf cut: Cuts all the way through the board

- Partial-kerf cut: Cuts only partway through the board

- Scoring: Makes a shallow cut to guide subsequent cuts

- V-kerf cut: Creates a V-shaped groove in the board

- Compound-kerf cut: Combines multiple kerf cuts to create complex shapes

Applications

- Through-kerf cut: Dividing boards into smaller pieces

- Partial-kerf cut: Cutting rabbets, dadoes, and tenons

- Scoring: Guiding circular or band saws for precision cuts

- V-kerf cut: Creating decorative edges and grooves

- Compound-kerf cut: Making intricate designs and shapes

3. How do you set up and calibrate a kerfer machine?

- Install appropriate blade for the desired cut

- Adjust blade height and angle according to cut specifications

- Set fence and miter gauge for cutting accuracy

- Test machine by making a few practice cuts

- Make any necessary adjustments until desired results are achieved

4. How do you inspect cut boards for defects and ensure they meet specifications?

- Examine boards for cracks, splits, or other damage

- Measure boards to ensure they meet length and width specifications

- Check boards for squareness and accuracy

- Identify and mark any defective boards

- Reject boards that do not meet quality standards

5. What are the safety precautions to consider when operating a kerfer machine?

- Wear appropriate safety gear such as gloves, eye protection, and hearing protection

- Keep hands and fingers away from the blade

- Never reach over or behind the running machine

- Use push sticks or blocks to feed boards through the machine

- Securely clamp workpieces before cutting

- Keep the work area clean and free of debris

- Disconnect the machine from power before performing any maintenance or repairs

6. How do you perform basic maintenance on a kerfer machine?

- Clean the machine regularly to remove dust and debris

- Lubricate moving parts according to manufacturer’s instructions

- Sharpen or replace the blade as needed

- Inspect electrical connections and tighten any loose wires

- Check belts for wear and tension, and replace if necessary

- Report any major issues or damage to the supervisor

7. What are some common troubleshooting techniques for kerfer machine problems?

- Machine not cutting cleanly: Check blade sharpness and adjust cutting angle

- Boards not feeding smoothly: Inspect feed rollers and adjust pressure

- Machine making excessive noise: Check bearings and belts for wear

- Electrical issues: Verify power supply and check electrical connections

- Other problems: Consult the manufacturer’s manual or seek professional assistance

8. What is your experience with different types of kerfer machines and materials?

- Types of kerfer machines: Manual, semi-automatic, automatic

- Materials: Plywood, MDF, hardwoods, softwoods, laminates

- Experience: Describe specific projects or tasks

- Proficiency: Highlight your ability to operate different machines and cut various materials

- Knowledge: Discuss your understanding of machine capabilities and material properties

9. How do you prioritize tasks and handle multiple projects simultaneously?

- Prioritization: Analyze tasks based on urgency, importance, and deadlines

- Multitasking: Break down projects into smaller tasks and work on multiple tasks concurrently

- Organization: Use tools and techniques to stay organized and track progress

- Communication: Communicate with supervisors and colleagues to coordinate tasks

- Adaptability: Adjust priorities and strategies as needed to meet changing demands

10. Describe a situation where you had to resolve a technical issue with a kerfer machine.

- Problem Identification: Describe the issue and how you identified it

- Troubleshooting: Outline the steps you took to diagnose the problem

- Resolution: Explain how you resolved the issue and restored machine functionality

- Learning Outcome: Discuss what you learned from the experience and how it improved your skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kerfer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kerfer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kerfer Machine Operators are responsible for operating kerfer machines, which are used to create narrow slits or grooves in materials such as wood, plastic, or metal.

1. Operate Kerfer Machines

Kerfer Machine Operators must be able to set up, operate, and maintain kerfer machines.

- Set up kerfer machines according to specifications

- Operate kerfer machines to create narrow slits or grooves in materials

- Maintain kerfer machines to ensure they are operating properly

2. Inspect Materials and Products

To ensure that materials and products meet specifications, Kerfer Machine Operators must be able to inspect them.

- Inspect materials for defects before kerfing

- Inspect products after kerfing to ensure they meet specifications

- Reject materials or products that do not meet specifications

3. Maintain Work Area

Maintaining a clean and safe work area is essential for Kerfer Machine Operators.

- Clean work area regularly

- Dispose of waste materials properly

- Follow safety procedures to prevent accidents

4. Communicate with Supervisors and Coworkers

Kerfer Machine Operators must be able to communicate effectively with supervisors and coworkers.

- Report any problems or issues to supervisors

- Request assistance from coworkers when needed

- Follow instructions from supervisors and coworkers

Interview Tips

To ace an interview for a Kerfer Machine Operator position, candidates should prepare by researching the company, the position, and the industry. They should also practice answering common interview questions and prepare questions to ask the interviewer.

1. Research the Company, Position, and Industry

Before the interview, candidates should research the company, the position, and the industry. This will help them understand the company’s culture, the position’s responsibilities, and the industry’s trends. Candidates can research the company’s website, annual reports, and news articles. They can also research the position’s responsibilities by reading the job description and talking to people who work in similar positions.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions. This will help them feel more confident and prepared during the interview. Some common interview questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “How do you handle stress?”

- “What are your salary expectations?”

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask the interviewer include:

- “What are the biggest challenges facing the company right now?”

- “What are the company’s goals for the next year?”

- “What is the company’s culture like?”

- “What is the training program like for new employees?”

- “What are the opportunities for advancement within the company?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Kerfer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!