Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Kettleman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

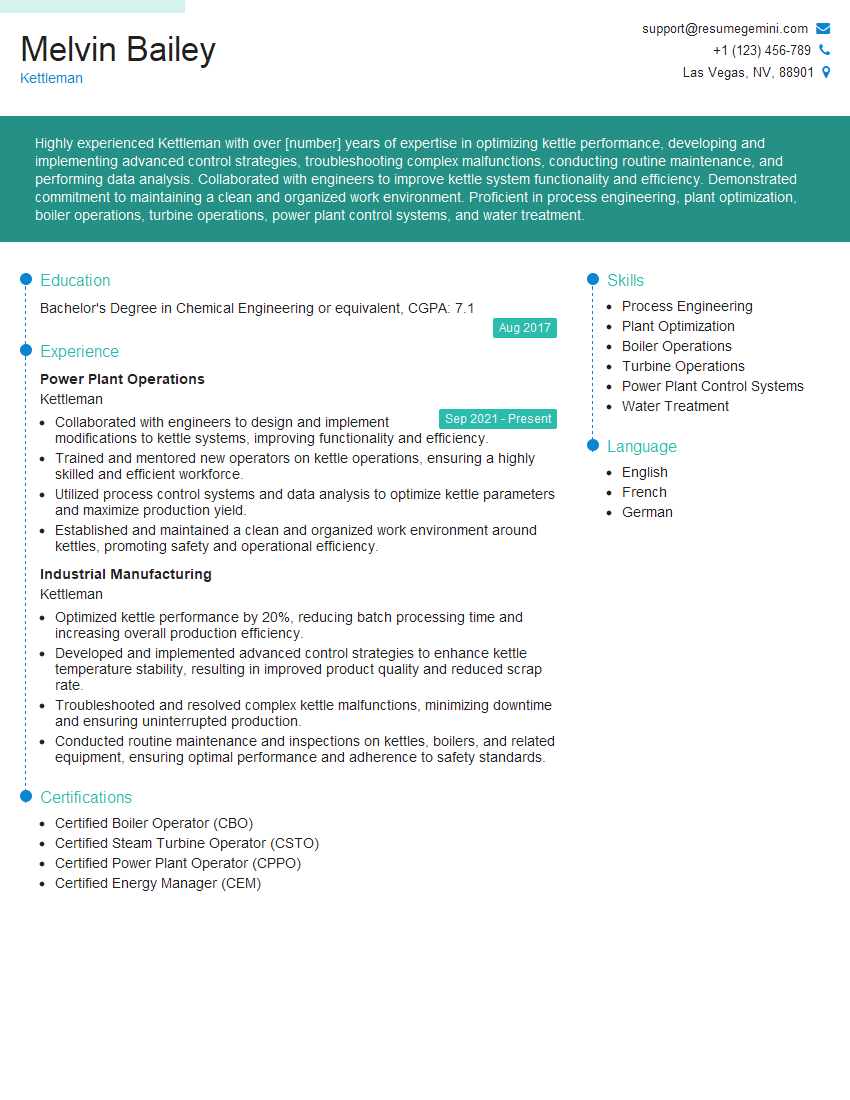

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kettleman

1. How would you design a Kettleman for a new chemical process?

- Conduct a thorough analysis of the chemical process to determine the required capacity, pressure, and temperature.

- Select appropriate materials of construction that can withstand the process conditions and prevent corrosion.

- Determine the optimal design for the Kettleman, including the shape, size, and internal components.

- Consider factors such as heat transfer efficiency, fluid flow, and safety requirements.

2. What are the key operating parameters to monitor and control in a Kettleman, and how would you ensure their stability?

Temperature control

- Utilize temperature sensors and controllers to maintain a precise temperature range.

- Adjust heat input or cooling mechanisms to regulate temperature.

Pressure control

- Employ pressure sensors and regulators to monitor and maintain the desired pressure.

- Vent or introduce gases to adjust pressure.

Agitation control

- Use agitators to prevent settling and ensure uniform mixing.

- Adjust agitation speed and impeller design to optimize mixing efficiency.

3. How would you handle a situation where a Kettleman is experiencing a leak?

- Identify the source of the leak and take immediate action to stop it.

- Assess the severity of the leak and determine if it poses a safety hazard.

- Isolate the Kettleman and repair the leak as quickly as possible.

- Investigate the cause of the leak and implement preventive measures to avoid future occurrences.

4. Describe your experience in troubleshooting Kettleman operations and the techniques you have used.

- Conduct visual inspections to identify potential issues.

- Use diagnostic tools such as temperature sensors, pressure gauges, and flow meters to monitor performance.

- Analyze data and identify deviations from normal operating parameters.

- Troubleshoot common issues such as temperature fluctuations, pressure drops, and agitation problems.

5. How do you ensure the safety of Kettleman operations, and what are the key safety protocols you follow?

- Adhere to all safety regulations and guidelines.

- Wear appropriate personal protective equipment.

- Regularly inspect Kettlemans for potential hazards.

- Develop and implement emergency response procedures.

- Train personnel on safety protocols and best practices.

6. What experience do you have in optimizing Kettleman performance to maximize efficiency?

- Analyze process data to identify areas for improvement.

- Implement modifications to the Kettleman design or operating parameters.

- Monitor performance and evaluate the effectiveness of optimization measures.

- Continuously seek ways to enhance efficiency and reduce operating costs.

7. How do you stay up-to-date with the latest advancements in Kettleman technology and best practices?

- Attend industry conferences and workshops.

- Read technical journals and white papers.

- Network with experts in the field.

- Participate in ongoing training and development programs.

8. Describe your experience in working with cross-functional teams in a chemical process environment.

- Collaborate effectively with engineers, operators, and maintenance personnel.

- Share knowledge and expertise to solve technical challenges.

- Contribute to decision-making processes that impact Kettleman operations.

- Foster a positive and collaborative work environment.

9. How do you prioritize your workload and manage multiple projects simultaneously?

- Set clear priorities and allocate time accordingly.

- Create a structured workflow and use project management tools.

- Delegate tasks and collaborate with team members.

- Monitor progress and adjust priorities as needed.

10. Describe a situation where you successfully resolved a complex technical problem related to Kettleman operations.

Analyze the problem, identify potential causes, and develop a solution plan.

- Collaborate with experts and gather data.

- Implement the solution and monitor its effectiveness.

- Document the solution and share it with stakeholders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kettleman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kettleman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kettlemen play a vital role in maintaining train operations by servicing and inspecting locomotives, carriages, and freight cars. They are responsible for diagnosing and resolving technical issues to ensure the safe and efficient operation of trains.

1. Locomotive and Rolling Stock Maintenance

Kettlemen are responsible for performing routine inspections, maintenance, and repairs on locomotives, carriages, and freight cars. This includes:

- Inspecting and repairing mechanical components such as engines, brakes, and electrical systems

- Lubricating and replacing parts as needed

- Conducting performance tests to ensure equipment is functioning properly

2. Troubleshooting and Problem Resolution

Kettlemen must be able to quickly and efficiently troubleshoot and resolve technical issues that arise during train operations. This involves:

- Diagnosing problems based on symptoms and error codes

- Performing repairs and adjustments to resolve issues

- Reporting any major issues or concerns to supervisors

3. Safety and Compliance

Kettlemen are responsible for maintaining a safe and compliant work environment. This includes:

- Following all safety protocols and procedures

- Using appropriate tools and equipment safely

- Reporting any safety hazards or concerns

4. Communication and Teamwork

Kettlemen must be able to communicate effectively with supervisors, colleagues, and train crews. They must also be able to work effectively as part of a team to complete tasks safely and efficiently.

Interview Tips

Preparing for an interview for a Kettleman position can help you increase your chances of success. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s culture, values, and the specific requirements of the Kettleman position. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the role.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in locomotive and rolling stock maintenance and repair. Provide specific examples of how you have successfully diagnosed and resolved technical issues in the past.

3. Demonstrate Your Problem-Solving Abilities

Kettlemen need to be able to quickly and efficiently solve problems. During your interview, be prepared to provide examples of how you have solved technical problems in the past. Explain your thought process and the steps you took to resolve the issue.

4. Show Your Safety Consciousness

Kettlemen are responsible for maintaining a safe work environment. Highlight your safety consciousness in your interview by emphasizing your adherence to safety protocols and procedures. Provide examples of how you have identified and resolved safety hazards in the past.

5. Prepare for Common Interview Questions

Research common interview questions for Kettlemen and prepare your answers in advance. This will help you feel confident and prepared during the interview.

Next Step:

Now that you’re armed with the knowledge of Kettleman interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Kettleman positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini