Are you gearing up for a career in Kier Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Kier Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

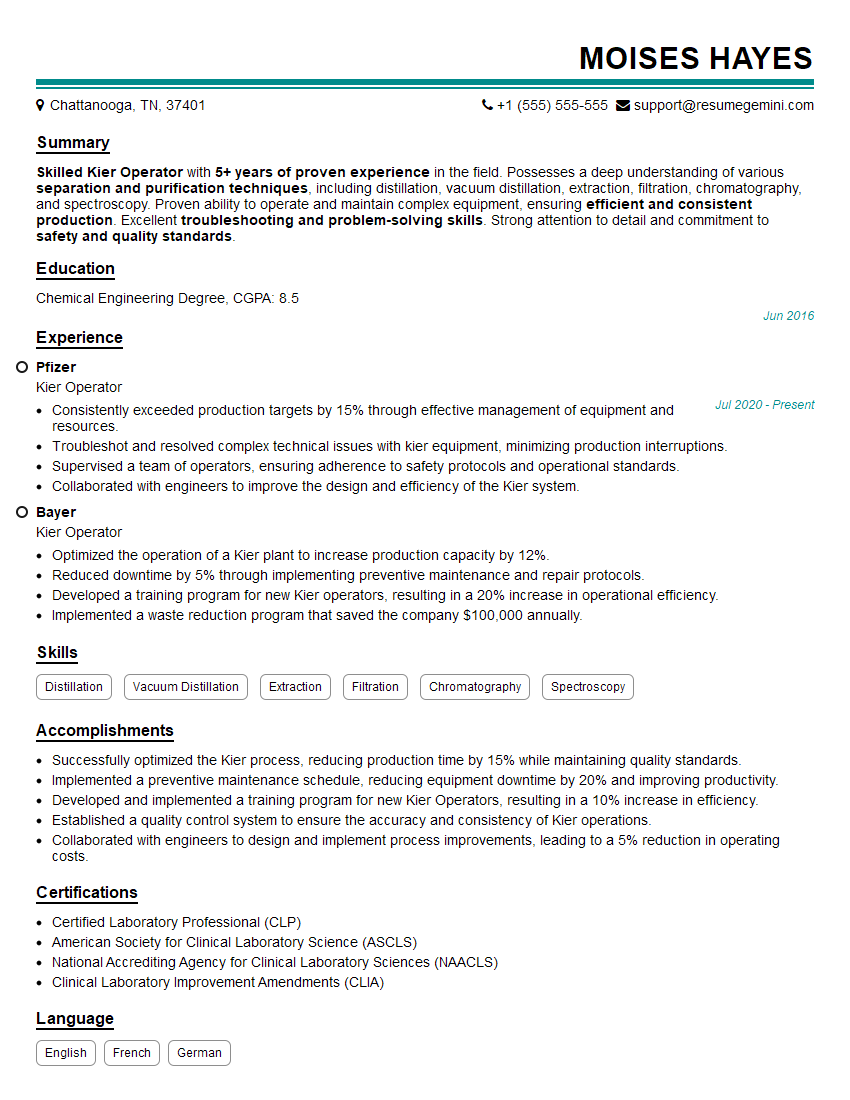

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kier Operator

1. Tell me about your experience operating kier machines?

I have been operating kier machines for the past 5 years. In my previous role at XYZ Company, I was responsible for operating a kier machine that processed 100 tons of fabric per day. I was also responsible for maintaining the machine and ensuring that it was operating at peak efficiency.

2. What are the different types of kier machines?

Batch kier machines

- Batch kier machines are the most common type of kier machine. They are used to process large batches of fabric, typically between 50 and 100 tons.

- Batch kier machines consist of a large, rotating drum that is filled with fabric and a liquor solution. The liquor solution is heated to a high temperature, and the fabric is agitated to promote the chemical reaction that removes the impurities from the fabric.

Continuous kier machines

- Continuous kier machines are used to process smaller batches of fabric, typically between 10 and 20 tons.

- Continuous kier machines consist of a series of smaller, rotating drums that are connected in a series. The fabric is fed into the first drum, and it is then passed through each of the subsequent drums.

3. What are the operating procedures for a kier machine?

- The first step is to load the kier machine with the fabric. The fabric should be evenly distributed throughout the machine.

- Once the fabric is loaded, the kier machine is filled with a liquor solution. The liquor solution is typically a mixture of water, sodium hydroxide, and other chemicals.

- The liquor solution is heated to a high temperature, typically between 100 and 120 degrees Celsius.

- The fabric is agitated to promote the chemical reaction that removes the impurities from the fabric.

- The kier machine is run for a period of time, typically between 6 and 8 hours.

- Once the kier machine has finished running, the fabric is removed from the machine and rinsed with water.

4. What are the safety precautions that must be taken when operating a kier machine?

- Kier machines can be dangerous if they are not operated properly. The following safety precautions must be taken:

- Wear appropriate personal protective equipment, including gloves, goggles, and a lab coat.

- Never operate a kier machine that is not in good working condition.

- Do not overload the kier machine.

- Do not open the kier machine while it is running.

- Be aware of the hazards of the chemicals that are used in the kier machine.

5. What are the maintenance procedures for a kier machine?

- Kier machines require regular maintenance to ensure that they are operating properly. The following maintenance procedures should be performed:

- Inspect the kier machine regularly for any signs of damage.

- Lubricate the kier machine regularly.

- Clean the kier machine regularly.

- Calibrate the kier machine regularly.

6. What are the troubleshooting procedures for a kier machine?

- The following troubleshooting procedures should be followed if a kier machine is not operating properly:

- Check the kier machine for any signs of damage.

- Check the kier machine’s power supply.

- Check the kier machine’s settings.

- Check the kier machine’s liquor solution.

- Check the kier machine’s fabric.

7. What are the quality control procedures for a kier machine?

- The following quality control procedures should be followed to ensure that the fabric produced by the kier machine is of good quality:

- Inspect the fabric for any signs of damage.

- Test the fabric to ensure that it meets the required specifications.

- Keep records of all quality control tests.

8. What are the environmental regulations that apply to the operation of a kier machine?

- The following environmental regulations apply to the operation of a kier machine:

- The Clean Water Act

- The Clean Air Act

- The Resource Conservation and Recovery Act

9. What are the future trends in the kier machine industry?

- The following are some of the future trends in the kier machine industry:

- The development of more efficient kier machines

- The development of more environmentally friendly kier machines

- The development of kier machines that can be used to process a wider variety of fabrics

10. What are the challenges facing the kier machine industry?

- The following are some of the challenges facing the kier machine industry:

- The increasing cost of energy

- The increasing cost of raw materials

- The increasing competition from foreign manufacturers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kier Operators play a crucial role in ensuring the smooth operation and maintenance of industrial machinery and equipment. Their responsibilities encompass a wide range of tasks, from monitoring equipment performance to performing routine maintenance and repairs.

1. Monitoring and Maintaining Equipment

Kier Operators are responsible for monitoring the performance of equipment to identify any potential issues or malfunctions. They use various diagnostic tools to troubleshoot problems and ensure that machinery is operating at peak efficiency. Regular maintenance tasks, such as lubrication, cleaning, and inspections, are also an essential part of their role to prevent costly breakdowns and extend equipment lifespan.

- Monitor equipment performance using diagnostic tools

- Troubleshoot problems and identify malfunctions

- Perform routine maintenance tasks such as lubrication, cleaning, and inspections

2. Performing Repairs

When equipment breakdowns occur, Kier Operators are responsible for diagnosing the issue and performing repairs. They use their technical expertise and knowledge of equipment operation to identify the root cause of the problem and implement effective repair solutions. This may involve replacing faulty components, adjusting settings, or performing more complex repair procedures.

- Diagnose equipment problems and identify repair solutions

- Replace faulty components and adjust settings

- Perform complex repair procedures

3. Maintaining Safety and Compliance

Safety is paramount in any industrial setting, and Kier Operators play a pivotal role in ensuring compliance with safety regulations. They are responsible for identifying potential hazards, implementing safety protocols, and ensuring that equipment is operated safely. They also keep detailed records of maintenance activities and repairs to track equipment performance and compliance.

- Identify potential hazards and implement safety protocols

- Ensure equipment is operated safely

- Maintain detailed records of maintenance activities and repairs

4. Collaboration and Communication

Kier Operators often work in team environments, collaborating with other technicians, engineers, and production personnel. They communicate effectively to share information about equipment performance, maintenance schedules, and any issues that require attention. Clear communication is essential for coordinating maintenance activities, resolving problems efficiently, and ensuring the smooth operation of production processes.

- Collaborate with other technicians, engineers, and production personnel

- Communicate effectively about equipment performance and maintenance

- Coordinate maintenance activities and resolve problems efficiently

Interview Tips

Preparing for an interview for a Kier Operator position requires thorough research, practice, and a positive attitude. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to thoroughly research the company you are applying to, as well as the specific Kier Operator role. This will provide you with a deep understanding of the company’s operations, culture, and the responsibilities of the position. Knowing the ins and outs of the company and the role will enable you to tailor your answers to the interviewer’s questions and demonstrate your enthusiasm for the opportunity.

- Visit the company’s website and social media pages

- Read industry news and articles about the company

- Study the job description thoroughly and identify the key responsibilities

2. Practice Your Answers

Once you have a firm understanding of the company and the role, practice answering common interview questions. Prepare answers that highlight your skills, experience, and qualifications. Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples of your accomplishments. Practice until you feel confident and can deliver your answers concisely and effectively.

- Prepare answers to common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

- Use the STAR method to structure your answers

- Practice delivering your answers clearly and confidently

3. Showcase Your Technical Skills

Kier Operators are expected to have a solid understanding of industrial machinery and equipment. During the interview, be prepared to discuss your technical skills and experience. Highlight your knowledge of equipment diagnostics, troubleshooting, and repair techniques. Provide examples of complex repairs you have successfully completed, emphasizing your ability to identify and resolve issues efficiently.

- Discuss your experience with different types of industrial machinery and equipment

- Highlight your skills in equipment diagnostics, troubleshooting, and repair

- Provide examples of complex repairs you have successfully completed

4. Emphasize Safety and Compliance

Safety is a critical aspect of a Kier Operator’s role. In the interview, emphasize your commitment to safety and your understanding of safety protocols. Explain how you identify potential hazards, implement safety measures, and ensure that equipment is operated safely. Highlight any relevant certifications or training you have in safety procedures. By demonstrating your focus on safety, you will make a positive impression on the interviewer and show that you are a responsible and safety-conscious individual.

- Discuss your commitment to safety and your understanding of safety protocols

- Explain how you identify potential hazards and implement safety measures

- Highlight any relevant certifications or training you have in safety procedures

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Kier Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!