Are you gearing up for a career in Kiln Burner Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Kiln Burner Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

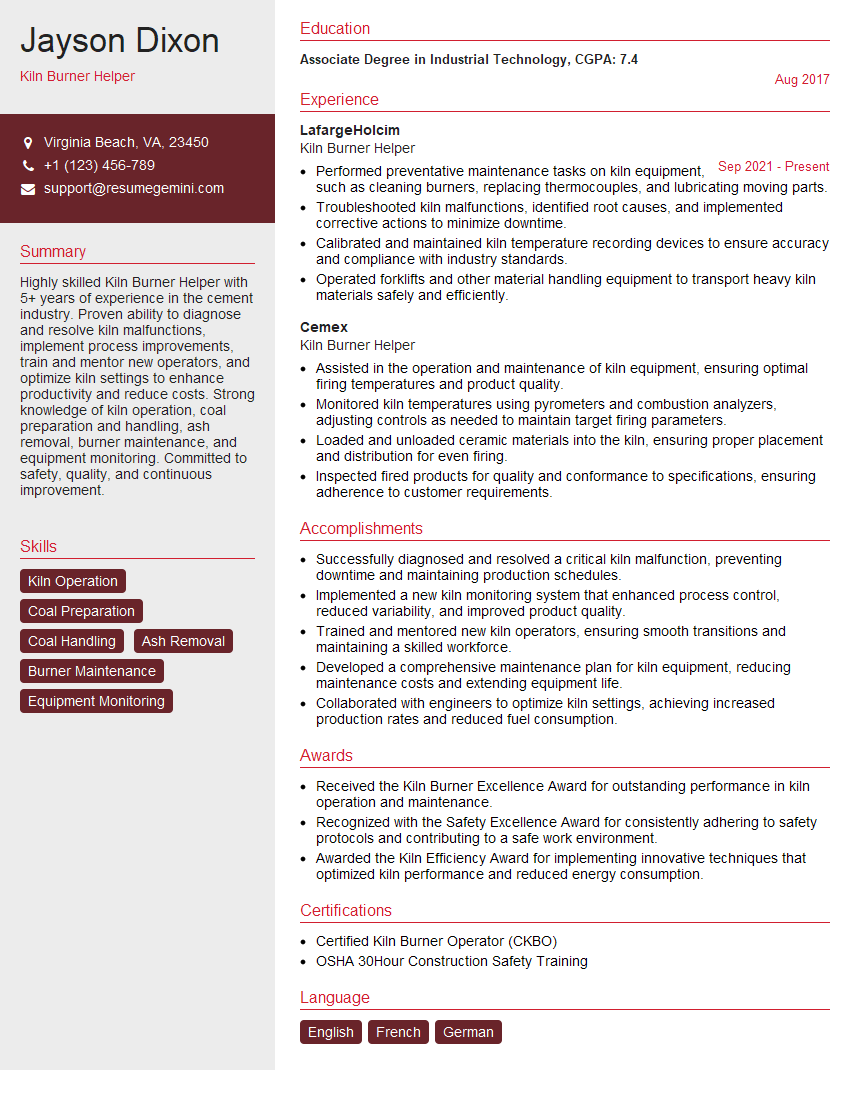

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Burner Helper

1. How would you monitor and control the firing process in a kiln to ensure the product meets the desired specifications?

As a Kiln Burner Helper, I would adhere to the following steps to monitor and control the firing process:

- Observe the kiln’s temperature gauges and make adjustments as needed to maintain the desired firing temperature.

- Monitor the flame and adjust the fuel-to-air ratio to ensure complete combustion and prevent overfiring.

- Inspect the product periodically to assess its quality and make any necessary adjustments to the firing process.

- Record all relevant data and observations to track the firing progress and identify any potential issues.

2. What safety precautions are essential to observe when working with high-temperature kilns?

Personal Protective Equipment:

- Wear appropriate personal protective equipment (PPE), including heat-resistant clothing, gloves, safety glasses, and ear protection.

- Ensure PPE is in good condition and fits properly to provide adequate protection.

Kiln Maintenance and Handling:

- Regularly inspect and maintain the kiln to prevent accidents or malfunctions.

- Avoid touching hot surfaces of the kiln or product without proper insulation.

- Handle heavy materials and kiln furniture with care to prevent injuries.

Work Environment:

- Keep the work area clean and free of tripping hazards or flammable materials.

- Ensure proper ventilation to prevent the accumulation of potentially hazardous gases or fumes.

3. How do you ensure the efficient and safe handling of fuel materials used in the firing process?

To ensure efficient and safe handling of fuel materials:

- Follow established procedures for receiving, storing, and transporting fuel.

- Store fuel in approved containers in well-ventilated and fire-resistant areas.

- Inspect fuel storage and handling equipment regularly to prevent leaks or spills.

- Train and supervise personnel involved in fuel handling to ensure they understand safety protocols.

- Regularly calibrate and maintain fuel metering and safety devices to ensure accurate fuel delivery and prevent overfeeding.

4. Describe the importance of maintaining a clean and organized work area in the kiln room.

Maintaining a clean and organized work area in the kiln room is crucial for several reasons:

- It ensures a safe work environment by eliminating tripping hazards and reducing the risk of fire or explosions.

- It promotes efficient workflow by minimizing clutter and allowing easy access to tools and materials.

- It reduces the risk of contamination or damage to products by preventing dirt or debris from entering the kiln.

- It creates a professional and visually appealing work environment.

5. How would you troubleshoot common problems encountered in the kiln firing process?

To troubleshoot common kiln firing problems, I would follow these steps:

- Identify the symptoms of the problem, such as uneven firing, product defects, or kiln malfunction.

- Check the kiln’s settings and make sure they are correct for the firing process.

- Inspect the kiln’s equipment, including thermocouples, burners, and fans, for any signs of damage or wear.

- Review the fuel supply and ensure that it is adequate and free of contaminants.

- Consult with more experienced colleagues or technical manuals to gather additional insights and potential solutions.

6. How do you calculate the amount of fuel required for a specific kiln firing?

To calculate the amount of fuel required for a kiln firing, I would consider several factors:

- The size and type of kiln.

- The desired firing temperature and duration.

- The type of fuel being used.

- The efficiency of the kiln and burners.

Based on these factors, I would use established formulas or consult with technical experts to determine the optimal fuel quantity.

7. How do you ensure the quality of the fired products?

To ensure the quality of the fired products, I would implement the following measures:

- Monitor the kiln’s temperature and atmosphere throughout the firing process.

- Inspect the products during and after firing to identify any defects or imperfections.

- Follow established quality control procedures and document the firing process and product inspections.

- Provide feedback to the kiln operator and management to improve firing techniques and product quality.

8. What is the importance of communication and teamwork in the kiln room?

Effective communication and teamwork in the kiln room are vital for:

- Ensuring a safe and efficient work environment.

- Coordinating kiln operations, including loading, firing, and unloading.

- Troubleshooting problems and resolving issues promptly.

- Maintaining a positive and supportive work culture.

9. How do you prioritize tasks and manage your time in a busy kiln room?

To prioritize tasks and manage my time effectively, I would:

- Identify the most important and urgent tasks.

- Create a work schedule and stick to it as much as possible.

- Delegate tasks to other team members when appropriate.

- Take breaks to maintain focus and productivity.

- Seek assistance from supervisors or colleagues when needed.

10. What is your understanding of the environmental regulations related to kiln operations?

My understanding of the environmental regulations related to kiln operations includes:

- Air quality standards for emissions, such as particulate matter and sulfur oxides.

- Waste management and disposal regulations for kiln waste, such as ash and glaze.

- Energy efficiency requirements and measures to reduce energy consumption.

- The importance of compliance and the consequences of non-compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Burner Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Burner Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Kiln Burner Helper is responsible for assisting in the operation and maintenance of a kiln, a furnace used in the production of various materials such as cement, bricks, and ceramics. Their primary duties include:

1. Kiln Operation

Assist in monitoring and adjusting the kiln’s temperature, pressure, and other operating parameters to ensure efficient and optimal firing processes.

- Operate and monitor kiln control systems.

- Maintain proper fuel and air flow into the kiln.

2. Fuel Management

Handle and manage fuel sources used in the kiln, such as coal, gas, or oil.

- Ensure a steady and adequate fuel supply.

- Monitor fuel consumption and adjust settings as needed.

3. Equipment Maintenance

Perform routine maintenance and repairs on kiln equipment, including burners, conveyors, and other mechanical systems.

- Inspect and lubricate machinery.

- Identify and troubleshoot potential issues.

4. Safety and Environmental Compliance

Adhere to strict safety protocols and environmental regulations related to kiln operations.

- Wear appropriate protective gear.

- Monitor emissions and ensure compliance with environmental standards.

Interview Tips

Preparing thoroughly for a Kiln Burner Helper interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry standing. Research the specific role and its responsibilities to demonstrate your genuine interest and understanding of the position.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize your experience and skills that align with the job requirements. Quantify your accomplishments whenever possible to showcase your impact.

3. Practice Common Interview Questions

Prepare answers to common interview questions related to your technical abilities, safety knowledge, problem-solving skills, and teamwork experience. Anticipate questions about specific kiln operations and maintenance procedures.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive punctually for your interview. Maintain a positive and enthusiastic demeanor throughout the interaction.

5. Ask Informed Questions

Show your engagement and interest by asking thoughtful questions about the company, the role, and the industry. This demonstrates your curiosity and desire to learn more.

6. Follow Up

After the interview, follow up with a thank-you note expressing your appreciation for the opportunity. Reiterate your interest in the position and highlight any additional qualifications that may have come up during the discussion.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Kiln Burner Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Kiln Burner Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.