Are you gearing up for a career in Kiln Fireman? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Kiln Fireman and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

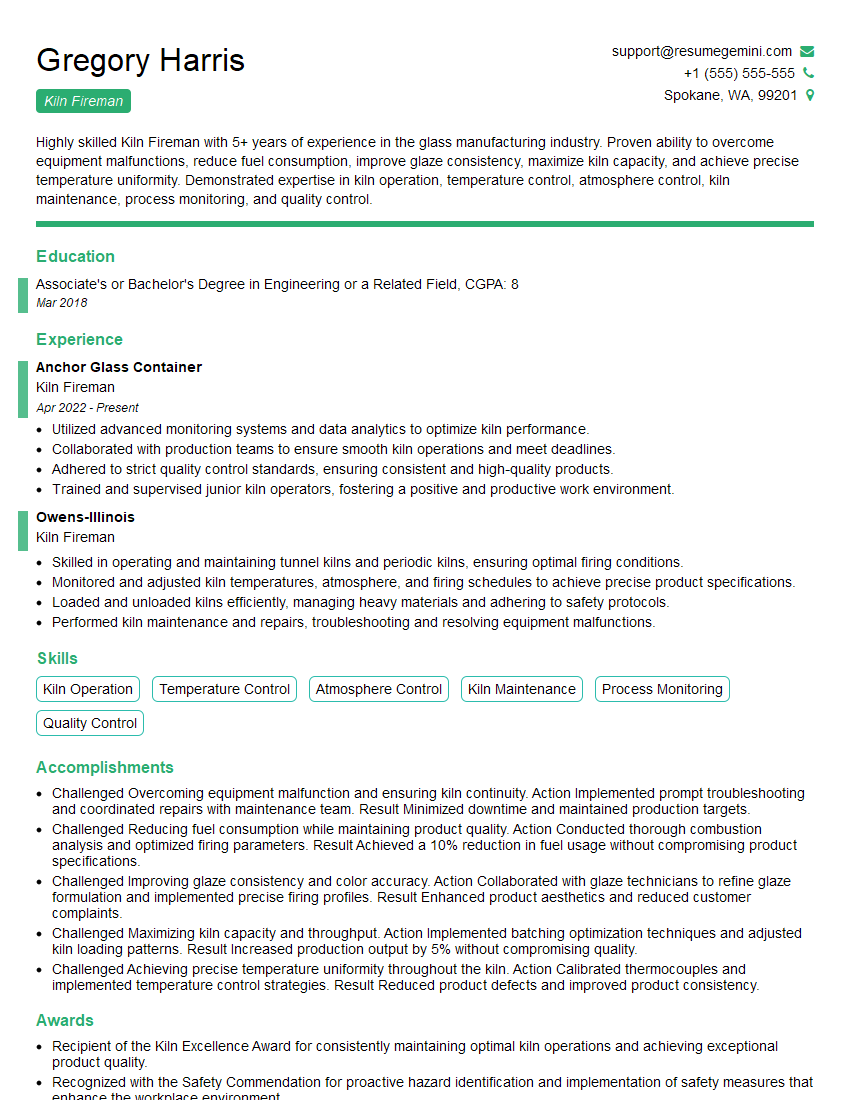

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Fireman

1. Describe the steps involved in loading a kiln with ceramic ware?

- Inspect ceramic ware for any defects or damage.

- Select the appropriate kiln furniture and place it inside the kiln.

- Carefully place the ceramic ware onto the kiln furniture, ensuring that pieces are not touching.

- Use spacers and props to support and separate pieces as needed.

- Arrange the ceramic ware to maximize space utilization and ensure proper airflow.

2. Explain the different firing stages and how they affect the properties of ceramic ware?

Bisque Firing

- Removes moisture from the clay body.

- Makes the ware porous and ready for glazing.

Glaze Firing

- Melts and fuses the glaze to the ceramic body.

- Creates a protective and decorative surface.

3. How do you determine the optimal firing temperature for different types of ceramic ware?

Factors to consider:

- Type of clay body (e.g., earthenware, stoneware, porcelain)

- Maturity of the clay body (e.g., low fire, mid-fire, high fire)

- Type of glaze being used

- Desired results (e.g., strength, porosity, color)

Use testing and experience to establish firing ranges for different materials.

4. How do you maintain a consistent temperature in the kiln?

- Calibrate the kiln regularly using a reliable pyrometer.

- Monitor the kiln temperature closely throughout the firing cycle.

- Adjust the fuel flow or electrical power as needed to maintain the desired temperature.

- Use a kiln sitter or other automated system to maintain temperature stability.

5. What safety precautions should be taken when operating a kiln?

- Wear appropriate protective gear (e.g., gloves, safety glasses, mask).

- Ensure adequate ventilation to avoid exposure to fumes.

- Keep flammable materials and sources of ignition away from the kiln.

- Let the kiln cool completely before unloading to prevent thermal shock.

- Follow all manufacturer’s instructions and safety protocols.

6. How do you troubleshoot common kiln problems, such as uneven firing or glaze defects?

Uneven Firing:

- Check for faulty thermocouples or heating elements.

- Ensure proper kiln loading and ventilation.

Glaze Defects:

- Examine the glaze recipe and firing schedule.

- Inspect the ceramic ware for contamination or improper preparation.

7. What is the importance of keeping a detailed kiln log?

- Tracks firing parameters for each kiln run.

- Helps identify successful firing schedules and troubleshoot problems.

- Provides a record for quality control and documentation.

- Facilitates learning and improvement over time.

8. Describe the different kiln firing methods (e.g., oxidation, reduction)?

- Oxidation: Firing in an oxygen-rich atmosphere, resulting in brighter colors and higher porosity.

- Reduction: Firing in an oxygen-deprived atmosphere, producing darker colors and lower porosity.

9. What is the role of cone packs in kiln firing?

- Used to monitor the temperature inside the kiln.

- Made of ceramic cones that bend at specific temperatures.

- Help determine when the kiln has reached the desired temperature.

10. Explain the importance of understanding the clay body and glaze chemistry?

- Influences the firing behavior and properties of ceramic ware.

- Helps optimize firing schedules and prevent glaze defects.

- Allows for experimentation and development of new ceramic materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Fireman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Fireman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Kiln Fireman is responsible for the operation and maintenance of the kiln, a critical piece of equipment used in the manufacturing process of various materials such as cement, lime, and ceramics. The key responsibilities include:

1. Kiln Operation and Monitoring

Monitoring and adjusting kiln temperature, feed rate, and other operating parameters to ensure optimal production.

- Observing and interpreting kiln gauges, instruments, and readings to maintain stable operating conditions.

- Adjusting fuel flow, airflow, and other inputs to control kiln conditions and optimize product quality.

2. Kiln Maintenance and Repair

Conducting regular inspections and preventive maintenance to keep the kiln in good working order.

- Inspecting kiln equipment, including burners, blowers, and refractory linings, for signs of wear or damage.

- Performing basic repairs and troubleshooting common kiln malfunctions to ensure smooth operation.

3. Product Quality Control

Monitoring product quality and making adjustments to kiln settings as needed to meet specifications.

- Taking samples of kiln products for quality testing and analysis.

- Adjusting kiln operating parameters based on test results to optimize product quality and minimize defects.

4. Safety and Environmental Compliance

Ensuring a safe and environmentally compliant work environment

- Following established safety protocols and wearing appropriate personal protective equipment.

- Monitoring kiln emissions and taking corrective actions to comply with environmental regulations.

Interview Preparation Tips

To ace an interview for a Kiln Fireman position, candidates should prepare thoroughly and demonstrate their knowledge, skills, and experience in the following areas:

1. Technical Knowledge and Skills

Candidates should have a solid understanding of kiln operation, maintenance, and troubleshooting.

- Familiarize yourself with different types of kilns and their operating principles.

- Practice interpreting kiln readings and making adjustments based on data.

- Highlight your experience in hands-on kiln maintenance and repair.

2. Problem-Solving Abilities

Kiln Firemen need to be able to identify and resolve kiln malfunctions quickly.

- Prepare examples of how you solved complex kiln issues in previous roles.

- Demonstrate your analytical and troubleshooting skills.

3. Attention to Detail

Kiln operation requires meticulous attention to detail.

- Emphasize your ability to observe and monitor kiln parameters closely.

- Provide instances where your attention to detail led to improved efficiency or prevented problems.

4. Communication and Teamwork

Kiln Firemen often work with other maintenance personnel and plant operators.

- Show that you can communicate effectively and collaborate with others.

- Give examples of how you communicated kiln operating data and maintenance needs clearly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Kiln Fireman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!