Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Kiln Furniture Caster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

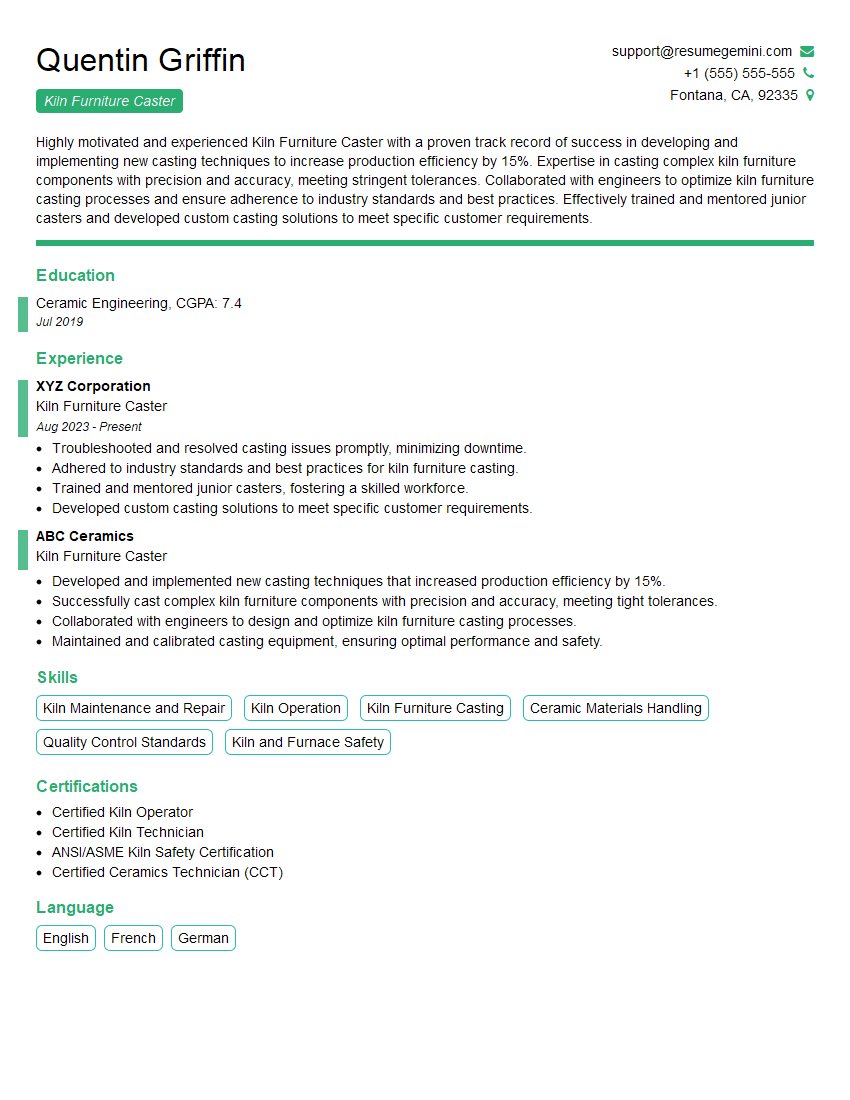

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Furniture Caster

1. Describe the process of manufacturing kiln furniture casters?

The manufacturing process of kiln furniture casters involves several key steps:

- Pattern making: Creating a mold or pattern that determines the shape of the caster.

- Mold preparation: Preparing the mold by applying a release agent and positioning it in a casting flask.

- Casting: Pouring molten metal, usually aluminum alloy, into the mold and allowing it to solidify.

- Knockout: Removing the casting from the mold after cooling.

- Finishing: Removing excess metal, cleaning, and polishing the caster.

- Inspection: Verifying the caster’s dimensions, quality, and conformance to specifications.

2. Explain the different types of materials used in kiln furniture casters and their properties?

Aluminum Alloys

- Lightweight and corrosion-resistant

- High strength-to-weight ratio

- Good electrical and thermal conductivity

Ceramic

- Resistant to high temperatures and thermal shock

- Good wear resistance and low thermal conductivity

- Can be used in high-temperature kiln applications

Stainless Steel

- Excellent corrosion resistance and high strength

- Resistant to wear and abrasion

- Suitable for use in harsh environments

3. How do you ensure the quality and consistency of kiln furniture casters?

To ensure quality and consistency, several measures are taken:

- Material selection: Using high-quality raw materials from reliable suppliers.

- Process control: Adhering to established casting processes and maintaining consistent parameters.

- Inspection: Implementing rigorous inspection procedures throughout the manufacturing process.

- Testing: Conducting performance testing, such as load testing, to verify compliance with specifications.

- Continuous improvement: Monitoring production processes, analyzing data, and implementing improvements to enhance quality.

4. Describe the different types of kiln furniture casters and their applications?

There are various types of kiln furniture casters, each designed for specific kiln applications:

- Flat casters: Used to support flatware, such as plates and tiles, in horizontal kilns.

- Round casters: Used to support cylindrical ware, such as vases and cups, in vertical kilns.

- Pin casters: Designed with pins to support delicate or complex pieces that require additional stability.

- Stellite casters: Used for high-temperature applications, such as firing porcelain and stoneware.

- Ceramic casters: Provide excellent thermal insulation and are suitable for firing glazes.

5. Explain the factors to consider when selecting kiln furniture casters?

When selecting kiln furniture casters, several factors should be taken into account:

- Type of kiln: Horizontal or vertical, and the size and shape of the kiln.

- Ware type: Shape, size, and weight of the pieces being fired.

- Kiln temperature: The maximum temperature that the casters will be exposed to.

- Loading capacity: The weight that the casters need to support.

- Material compatibility: Ensuring that the casters are compatible with the ware and kiln environment.

- Cost and availability: Balancing the cost of the casters with their performance and durability.

6. How do you handle customer complaints and resolve issues related to kiln furniture casters?

To handle customer complaints effectively, the following steps are taken:

- Active listening: Listening attentively to the customer’s concerns.

- Problem identification: Identifying the root cause of the issue.

- Solution development: Proposing and discussing possible solutions with the customer.

- Implementation: Implementing the agreed-upon solution promptly.

- Follow-up: Following up with the customer to ensure satisfaction and prevent recurrence.

7. How do you stay up-to-date with the latest advancements in kiln furniture casting technology?

To stay current with the industry, several proactive measures are taken:

- Attending industry conferences and workshops: Participating in events to learn about new technologies and trends.

- Reading technical publications and journals: Staying informed through industry literature and research.

- Researching online and through professional networks: Exploring online resources and connecting with experts.

- Collaborating with suppliers and manufacturers: Partnering with industry leaders to gain insights into cutting-edge developments.

8. Explain the importance of proper kiln furniture caster selection and usage?

Selecting and using the correct kiln furniture casters is crucial for several reasons:

- Product quality: Casters support the ware during firing, influencing the final product’s quality and reducing defects.

- Kiln longevity: Proper caster selection prevents damage to kiln shelves and elements, extending the kiln’s lifespan.

- Safety: Stable and secure casters minimize the risk of ware collapse or kiln damage.

- Efficiency: Using the appropriate casters ensures optimal firing conditions, saving time and energy.

- Cost-effectiveness: Correct caster choice reduces the likelihood of costly repairs or replacements.

9. How do you optimize kiln furniture caster performance?

To optimize kiln furniture caster performance, several strategies are employed:

- Matching casters to ware: Selecting casters that provide adequate support and stability for the specific ware being fired.

- Uniform distribution: Distributing casters evenly to prevent excessive loading on any single caster.

- Regular cleaning: Removing glaze or debris from casters to prevent damage and ensure smooth operation.

- Appropriate loading: Loading the kiln carefully to avoid overloading and caster failure.

- Maintenance: Inspecting and repairing casters regularly to ensure their integrity and functionality.

10. Describe any recent advancements or innovations in kiln furniture casting technology that you have observed?

Recent advancements in kiln furniture casting technology include:

- Improved materials: New alloys and ceramics with enhanced heat resistance and durability.

- Advanced casting techniques: Precision casting methods for increased accuracy and consistency.

- Automated casting systems: Automating the casting process for increased efficiency and reduced labor costs.

- Digital modeling and simulation: Computer-aided design and simulation tools for optimizing caster design and performance.

- Sustainable practices: Developing environmentally friendly casting processes and using recycled materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Furniture Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Furniture Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Kiln Furniture Caster plays a crucial role in the ceramics industry, ensuring the proper casting and firing of ceramic products. Their primary responsibilities include:

1. Casting Ceramic Molds

Using specialized casting techniques, Kiln Furniture Casters create intricate molds for casting ceramic pieces. They follow specific designs and specifications to ensure accurate and high-quality molds.

- Prepare and mix casting materials to achieve the desired consistency.

- Pour casting materials into molds and ensure even distribution throughout the mold.

2. Operating Kiln Equipment

Kiln Furniture Casters are responsible for operating kilns, which are specialized ovens used to fire and glaze ceramic products. They monitor and adjust kiln temperature, atmosphere, and firing cycles to achieve optimal results.

- Load and unload ceramic pieces into and out of the kiln.

- Control and maintain kiln temperature according to predetermined firing schedules.

3. Inspecting and Maintaining Kiln Furniture

Kiln Furniture Casters inspect and maintain kiln furniture, which are the ceramic supports used to hold ceramic pieces during firing. They ensure that the kiln furniture is in good condition and free from defects that could damage the ceramic products.

- Inspect kiln furniture for cracks, damage, and wear and tear.

- Clean and repair kiln furniture as necessary to maintain its functionality.

4. Quality Control and Assurance

Kiln Furniture Casters play a vital role in quality control and assurance. They inspect fired ceramic products for defects such as cracks, glaze imperfections, and color variations. They also conduct tests to ensure that the products meet the required specifications.

- Perform visual and tactile inspections of fired ceramic products.

- Conduct quality control tests, such as glaze durability and water absorption tests.

Interview Tips

Preparing for an interview for a Kiln Furniture Caster position requires thorough research and practice. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s history, products, and industry standing. Understand the specific requirements of the Kiln Furniture Caster role and how your skills and experience align with them.

- Visit the company’s website, read industry news, and connect with employees on LinkedIn.

- Identify key responsibilities and skills mentioned in the job description and prepare examples that showcase your capabilities.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses. Practice answering questions related to your technical skills, experience with kiln operation, quality control procedures, and troubleshooting abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your achievements whenever possible, using specific metrics and data.

3. Showcase Your Passion for Ceramics

Highlight your passion for ceramics and your understanding of the industry. Explain how your interest in the field has motivated you to develop your skills and pursue a career as a Kiln Furniture Caster.

- Share your knowledge of different ceramic techniques and firing processes.

- Discuss your experience with working with various types of clays and glazes.

4. Emphasize Your Attention to Detail

Kiln Furniture Casters must possess a high level of attention to detail. In the interview, emphasize your ability to focus on precision, accuracy, and consistency in all aspects of your work.

- Provide examples of how you have maintained meticulous attention to detail in previous roles.

- Explain how your organizational skills and quality control mindset enable you to excel in detail-oriented tasks.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that show your curiosity about the company, the industry, and the specific role.

- Ask about the company’s approach to innovation and product development.

- Inquire about the opportunities for professional growth and advancement within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Kiln Furniture Caster, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Kiln Furniture Caster positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.