Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Kiln Loader interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Kiln Loader so you can tailor your answers to impress potential employers.

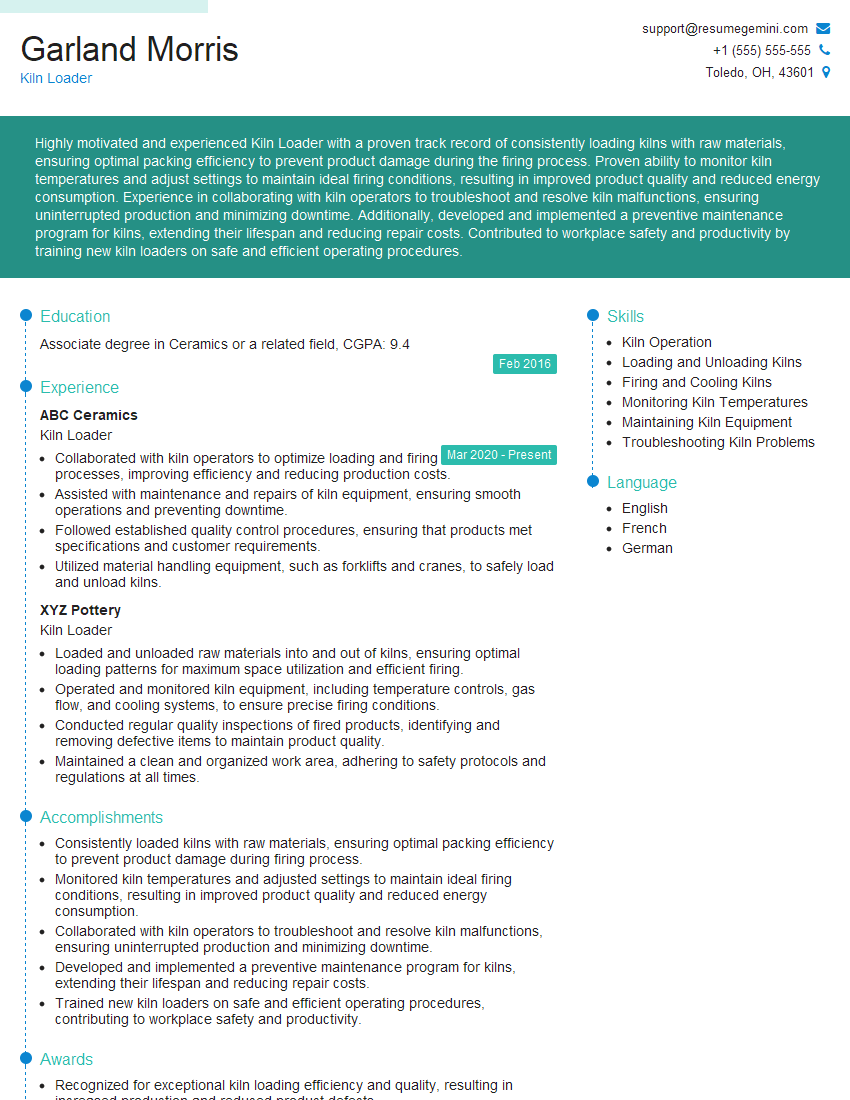

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Loader

1. How do you ensure that the kiln is loaded properly to prevent damage to the kiln or the products being fired?

- By following the loading guidelines provided by the kiln manufacturer.

- By ensuring that the products are evenly distributed throughout the kiln.

- By not overloading the kiln.

- By using proper spacers and supports to prevent the products from shifting during firing.

2. What are the different types of kilns and what are their advantages and disadvantages?

Types of Kilns

- Electric Kilns

- Gas Kilns

- Wood-Fired Kilns

- Salt Kilns

Advantages and Disadvantages

- Electric Kilns: Advantages – Precise temperature control, clean operation, Disadvantages – High operating costs.

- Gas Kilns: Advantages – Lower operating costs, Disadvantages – Less precise temperature control than electric kilns.

- Wood-Fired Kilns: Advantages – Unique aesthetic effects, Disadvantages – Difficult to control temperature, requires skilled operator.

- Salt Kilns: Advantages – Produces unique salt-glazed finishes, Disadvantages – Complex and dangerous process.

3. How do you troubleshoot common kiln problems, such as uneven firing, glaze defects, and cracking?

- Uneven Firing: Causes – Improper kiln loading, faulty thermocouples, uneven heat distribution, Disadvantages – Firing the kiln at too high or too low a temperature.

- Glaze Defects: Causes – Incorrect glaze application, incompatible glazes, firing at the wrong temperature, Disadvantages – Contamination of the glaze.

- Cracking: Causes – Overloading the kiln, using incompatible clays, firing the kiln too quickly, Disadvantages – Improper drying of the clay.

- Solutions: Re-load the kiln properly, replace faulty thermocouples, adjust heat distribution, fire at the correct temperature, apply glaze correctly, use compatible glazes, fire at the correct temperature, prevent contamination of the glaze, load the kiln properly, use compatible clays, fire the kiln slowly, dry the clay properly.

4. What are the safety precautions that you take when operating a kiln?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensure that the kiln is properly ventilated to prevent the buildup of toxic fumes.

- Never open the kiln door during firing, as this can cause an explosion.

- Allow the kiln to cool completely before unloading it.

- Be aware of the potential for electrical hazards and follow all electrical safety guidelines.

5. How do you maintain a kiln to ensure its longevity and efficiency?

- Clean the kiln regularly to remove any debris or glaze buildup.

- Inspect the kiln elements and thermocouples regularly for any damage.

- Calibrate the kiln regularly to ensure that it is firing at the correct temperature.

- Follow the manufacturer’s instructions for proper operation and maintenance.

6. What are the different types of kiln furniture and how are they used?

- Shelves: Used to support the products during firing.

- Posts: Used to support the shelves.

- Cones: Used to indicate the temperature inside the kiln.

- Wedges: Used to level the shelves.

- Stilts: Used to elevate the products off the shelves.

7. How do you calculate the firing schedule for a kiln?

- Determine the desired firing temperature.

- Consult the manufacturer’s instructions for the recommended firing schedule for the type of kiln and products being fired.

- Adjust the firing schedule as needed based on the experience and knowledge of the kiln operator.

8. What is the difference between bisque firing and glaze firing?

- Bisque Firing: The first firing of the clay product, which hardens the clay and makes it porous.

- Glaze Firing: The second firing of the clay product, which melts the glaze and creates a glossy finish.

9. What are the different types of glazes and what are their characteristics?

- Clear Glazes: Transparent glazes that allow the color of the clay body to show through.

- Opaque Glazes: Opaque glazes that hide the color of the clay body.

- Glossy Glazes: Glazes that have a shiny finish.

- Matte Glazes: Glazes that have a dull finish.

- Crystalline Glazes: Glazes that contain crystals that give the glaze a unique appearance.

10. How do you unload a kiln safely and efficiently?

- Allow the kiln to cool completely before unloading it.

- Wear appropriate PPE, including gloves and safety glasses.

- Open the kiln door slowly and carefully.

- Use kiln tongs to remove the products from the kiln.

- Be careful not to touch the hot kiln elements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Kiln Loader

A Kiln Loader is responsible for operating and maintaining kiln equipment, ensuring the safe and efficient loading and unloading of materials into and out of the kiln. The role plays a vital role in the production process of various industries, including ceramics, cement, and chemicals. Key responsibilities include:

1. Kiln Operation

- Loading materials such as raw materials, products, or waste into the kiln using conveyor belts, hoppers, or other equipment.

- Monitoring and controlling the kiln’s temperature, speed, and other operating parameters to ensure optimal conditions for the specific process.

- Unloading materials from the kiln once the process is complete, using conveyors, hoppers, or other methods.

2. Equipment Maintenance

- Performing routine maintenance and minor repairs on kiln equipment, including conveyors, hoppers, and other mechanical components.

- Inspecting and cleaning equipment regularly to prevent breakdowns and ensure optimal performance.

- Following established safety protocols and procedures to maintain a safe and healthy work environment.

3. Quality Control

- Monitoring the quality of materials being loaded and unloaded from the kiln to ensure they meet specifications.

- Identifying and resolving any quality issues promptly to prevent product defects.

- Keeping accurate records of kiln operations and any quality-related incidents.

4. Safety and Compliance

- Adhering to all safety regulations and procedures when operating the kiln and handling materials.

- Wearing appropriate personal protective equipment (PPE) and following established safety protocols.

- Participating in safety training and drills to maintain a high level of safety awareness.

Interview Tips for Kiln Loader

Preparing for a Kiln Loader interview can help you present your skills and experience effectively and increase your chances of success. Here are some tips to consider:

1. Research the Industry and Company

- Familiarize yourself with the specific industry where kiln loaders are employed, such as ceramics, cement, or chemicals.

- Research the company you are applying to, including their products, processes, and safety policies.

2. Highlight Relevant Skills and Experience

- Emphasize your experience in operating and maintaining kiln equipment, including any specific types of kilns you have worked with.

- Describe your understanding of the principles of kiln operation, quality control, and safety.

3. Demonstrate Safety Awareness

- Stress your commitment to safety and your knowledge of safety regulations and procedures.

- Provide examples of your attention to detail and ability to identify and mitigate potential hazards.

4. Practice Common Interview Questions

- Prepare for questions about your experience, skills, and motivations for applying for the position.

- Consider questions related to safety, troubleshooting, and your ability to work independently and as part of a team.

5. Dress Professionally and Arrive on Time

- Present yourself in a professional and respectful manner, as it reflects your commitment to the job.

- Arrive on time for your interview to show punctuality and respect for the interviewer’s schedule.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Kiln Loader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!