Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Kiln Maintenance position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

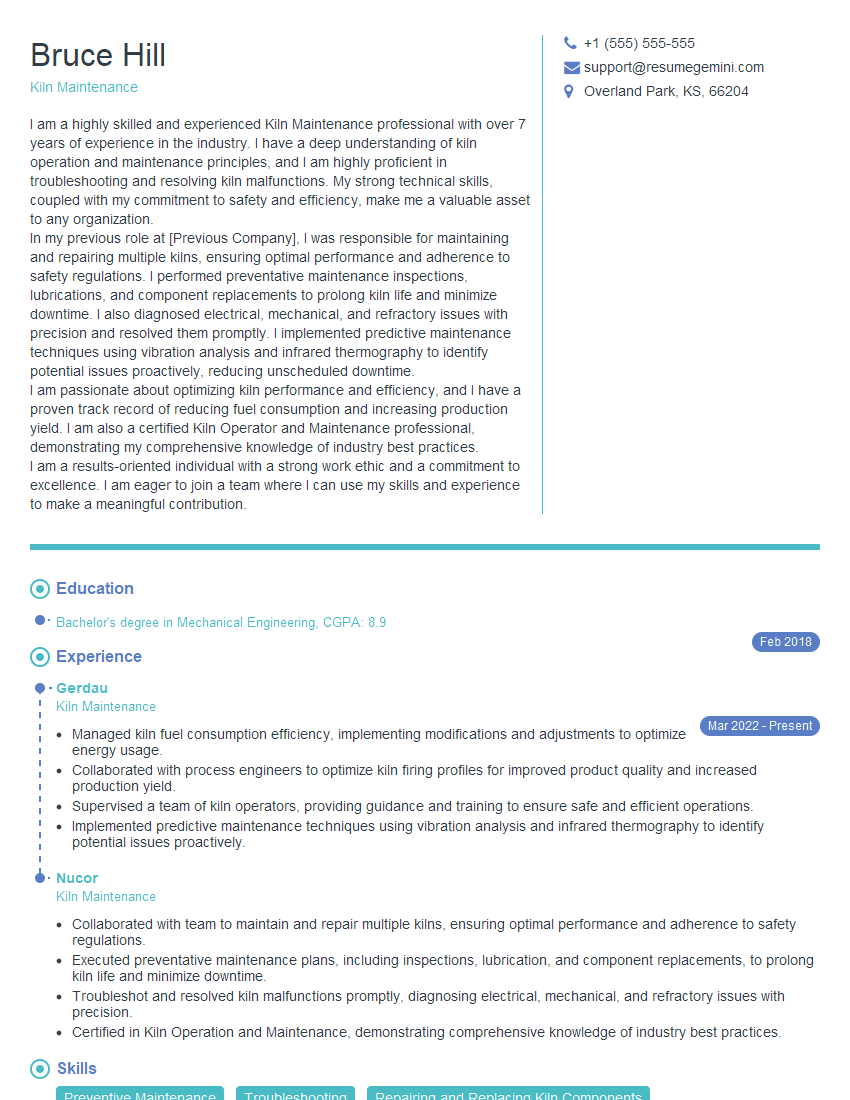

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Maintenance

1. Explain the process of inspecting and maintaining kiln motors?

The process involves several steps:

- Visual inspection: Checking for any physical damage, such as cracks, loose connections, or corrosion.

- Electrical testing: Using a multimeter to test voltage, resistance, and current to identify any electrical issues.

- Vibration analysis: Using a vibration analyzer to detect any abnormal vibrations that could indicate bearing problems or other mechanical issues.

- Lubrication: Ensuring that all bearings and other moving parts are properly lubricated to minimize wear and tear.

- Documentation: Recording all inspection and maintenance activities, including any repairs or replacements made.

2. Describe the types of refractory materials used in kiln linings and their properties?

Various types of refractory materials are used in kiln linings, each with specific properties:

- Fireclay refractories: Made from natural clay minerals, they offer good thermal stability and resistance to chemical attack.

- Silica refractories: Produced from silicon dioxide (SiO2), they have high melting points and excellent load-bearing capacity.

- Magnesia refractories: Composed primarily of magnesium oxide (MgO), they provide resistance to basic slags and high temperatures.

- Zirconia refractories: Derived from zirconium dioxide (ZrO2), they exhibit exceptional thermal shock resistance and high-temperature stability.

- Alumina refractories: Made from aluminum oxide (Al2O3), they offer excellent chemical inertness and resistance to wear and tear.

3. How do you monitor and control temperature uniformity within a kiln?

To ensure temperature uniformity:

- Temperature sensors: Multiple thermocouples or pyrometers are placed strategically throughout the kiln to measure temperature at different points.

- Burner control system: The burner system is controlled using feedback from the temperature sensors to adjust fuel flow and air supply.

- Zone control: The kiln may be divided into zones, each with its own temperature sensors and burner control, allowing for precise temperature management in specific areas.

- Regular monitoring: Temperature data is continuously monitored and recorded to identify any deviations or trends.

- Process adjustments: Based on the temperature monitoring data, adjustments can be made to the firing schedule or burner settings to optimize uniformity.

4. Describe the process of repairing cracks in kiln shells?

Repairing cracks in kiln shells involves the following steps:

- Inspection: The crack is thoroughly inspected to determine its extent and depth.

- Preparation: The area around the crack is cleaned and prepared to ensure proper adhesion of the repair material.

- Crack repair: High-temperature refractory cement, mortar, or welded plates are used to fill and seal the crack.

- Curing: The repair material is allowed to cure and bond properly, following the manufacturer’s instructions.

- Testing: The repaired area is tested to ensure that it is sealed and structurally sound.

5. Explain the safety precautions required when working with kilns?

Safety precautions for working with kilns include:

- Protective gear: Wearing appropriate protective clothing, such as heat-resistant gloves, goggles, and a respirator, when operating or near a kiln.

- Fire safety: Ensuring that the kiln is kept clear of flammable materials and that fire extinguishers are readily available.

- Ventilation: Maintaining proper ventilation to avoid exposure to harmful fumes or dust.

- Electrical safety: Inspecting and maintaining electrical connections to prevent electrical hazards.

- Training: Receiving proper training on kiln operation and safety procedures.

6. How do you troubleshoot problems with kiln burners?

Troubleshooting kiln burner problems involves:

- Checking fuel supply: Ensuring that there is a sufficient supply of fuel and that the fuel lines are not blocked.

- Inspecting ignition system: Verifying that the igniter is functioning properly and that the flame sensor is detecting the flame.

- Examining airflow: Checking that the burner is receiving the correct amount of combustion air.

- Monitoring flame pattern: Observing the flame pattern to identify any abnormalities, such as flickering or uneven distribution.

- Consulting manufacturer’s specifications: Referring to the kiln manufacturer’s instructions for recommended troubleshooting procedures.

7. Describe the different types of kiln insulation materials and their applications?

Kiln insulation materials include:

- Ceramic fiber: Lightweight and highly insulating, used in high-temperature applications.

- Firebrick: Durable and energy-efficient, used in kiln walls and floors.

- Mineral wool: Non-combustible and resistant to moisture, used in kiln roofs and ceilings.

- Perlite: A lightweight and porous material, used as a filler in insulation applications.

- Silica aerogel: An advanced insulation material with extremely low thermal conductivity.

8. Explain the principles of kiln cooling and the different methods used?

Kiln cooling involves gradually lowering the temperature of the kiln and its contents.

Cooling methods:

- Natural cooling: Allowing the kiln to cool slowly without any active cooling methods.

- Forced air cooling: Using fans or blowers to circulate air through the kiln, accelerating the cooling process.

- Water cooling: Spraying water on the kiln’s exterior or using water-cooled heat exchangers to transfer heat away.

- Controlled cooling schedules: Using programmable controllers to gradually reduce the kiln’s temperature over a specified period.

9. How do you assess the condition of kiln refractories?

Refractory condition assessment involves:

- Visual inspection: Checking for cracks, spalling, erosion, or other damage.

- Thermography: Using an infrared camera to detect areas of high temperature or refractory deterioration.

- Ultrasonic testing: Using ultrasonic waves to identify internal defects or delamination.

- Sampling and analysis: Taking samples of the refractories and analyzing their chemical and physical properties.

- Record keeping: Maintaining records of inspection and assessment results for future reference.

10. Explain the importance of kiln maintenance and its impact on overall kiln performance?

Kiln maintenance is crucial for:

- Safety: Ensuring the kiln operates safely and efficiently, preventing accidents or breakdowns.

- Efficiency: Maintaining optimal operating conditions, which maximizes fuel efficiency and reduces energy consumption.

- Product quality: Proper kiln maintenance helps achieve consistent and high-quality products.

- Equipment longevity: Regular maintenance extends the life of the kiln and its components.

- Cost-effectiveness: Preventive maintenance reduces the likelihood of costly repairs or replacements in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Maintenance‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kiln Maintenance personnel are responsible for the maintenance and repair of kilns, which are used in a variety of industries to heat and cool materials. Their responsibilities include:

1. Inspecting and maintaining kilns

Inspecting kilns for signs of wear and tear, and making repairs as needed. This may include checking the kiln’s refractory lining, burners, and electrical components.

- Identifying and fixing any issues that could lead to a kiln breakdown.

- Maintaining a preventative maintenance schedule to ensure that kilns are running efficiently and safely.

2. Troubleshooting and repairing kilns

Troubleshooting and repairing kilns that are not operating properly. This may involve diagnosing the problem, replacing parts, or making adjustments to the kiln’s settings.

- Using diagnostic tools to identify the source of the problem.

- Repairing or replacing damaged parts, such as burners, thermocouples, and refractory bricks.

3. Calibrating and adjusting kilns

Calibrating and adjusting kilns to ensure that they are operating within the desired temperature range. This may involve using a variety of tools and techniques, such as thermocouples, pyrometers, and control systems.

- Adjusting the kiln’s temperature settings to meet specific process requirements.

- Calibrating the kiln’s temperature sensors to ensure that they are accurate.

4. Monitoring and controlling kiln operations

Monitoring and controlling kiln operations to ensure that they are running smoothly and efficiently. This may involve monitoring the kiln’s temperature, pressure, and other operating parameters.

- Observing the kiln’s operation to identify any potential problems.

- Making adjustments to the kiln’s settings to maintain optimal operating conditions.

Interview Tips

To ace an interview for a position as a Kiln Maintenance personnel, it is important to be well-prepared and to have a strong understanding of the job responsibilities. Here are a few tips that can help you prepare for the interview:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also give you a better understanding of the job responsibilities and requirements.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and news articles to learn about the latest trends and developments in the field.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Use the STAR method to answer behavioral interview questions.

- Prepare specific examples of your experience and skills that demonstrate your qualifications for the position.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Plan your route in advance and give yourself plenty of time to get to the interview location.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position and the company. Be sure to show your excitement for the opportunity and convey your confidence in your ability to perform the job responsibilities.

- Smile, make eye contact, and speak clearly and confidently.

- Be prepared to talk about your accomplishments and how you can contribute to the company.

Next Step:

Now that you’re armed with the knowledge of Kiln Maintenance interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Kiln Maintenance positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini