Are you gearing up for an interview for a Kiln Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Kiln Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

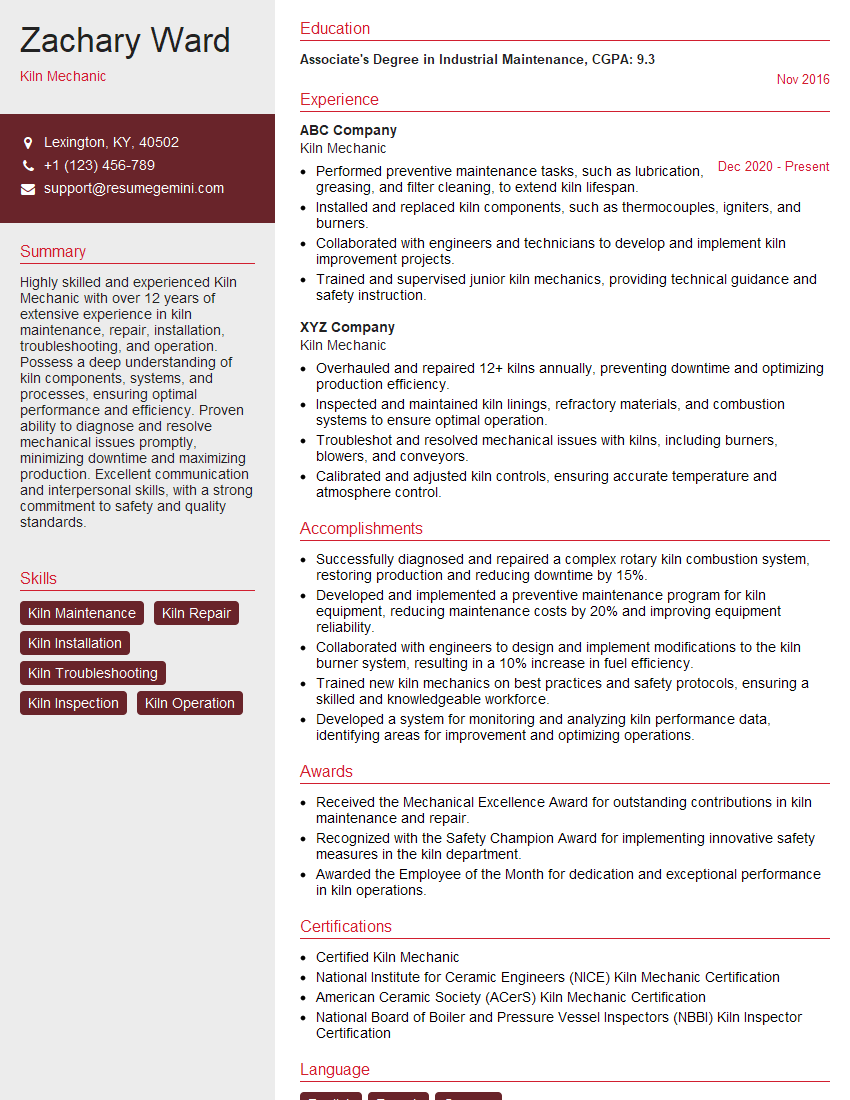

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Mechanic

1. What are the key responsibilities of a Kiln Mechanic?

The key responsibilities of a Kiln Mechanic include:

- Performing preventative maintenance and repairs on kilns and dryers

- Troubleshooting and resolving mechanical issues

- Installing, adjusting, and calibrating kiln equipment

- Working with other maintenance personnel to ensure optimal kiln operation

- Maintaining a clean and safe work environment

2. Describe the different types of kilns and their uses.

Electric Kilns

- Used for firing ceramics, glass, and other materials

- Heat up to 1800°F (1000°C)

Gas Kilns

- Used for firing ceramics, pottery, and other materials

- Heat up to 2300°F (1250°C)

Shuttle Kilns

- Continuous-feed kilns used for firing bricks, tiles, and other large-scale products

- Move product through the kiln on a conveyor belt

Tunnel Kilns

- Long, continuous-feed kilns used for firing bricks, tiles, and other large-scale products

- Product moves through the kiln on a series of cars

3. What are the most common problems that occur with kilns?

Some of the most common problems that occur with kilns include:

- Temperature fluctuations

- Burner issues

- Electrical problems

- Mechanical breakdowns

- Clogged or dirty burners

4. How do you troubleshoot and resolve a kiln problem?

When troubleshooting a kiln problem, I first try to identify the symptoms of the problem. Once I have identified the symptoms, I can begin to narrow down the possible causes. I will then use my knowledge of kiln mechanics to troubleshoot the problem and find a solution. If I am unable to resolve the problem myself, I will contact a qualified technician for assistance.

5. What are the safety precautions that must be taken when working with kilns?

When working with kilns, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator

- Never operate a kiln that is not in good working order

- Keep the work area clean and free of debris

- Be aware of the potential for fire and explosion

- Follow all manufacturer’s instructions for the safe operation of the kiln

6. How do you maintain a kiln to ensure optimal performance?

To maintain a kiln and ensure optimal performance, I perform the following tasks:

- Regularly clean the kiln and its components

- Inspect the kiln for any signs of damage or wear

- Calibrate the kiln’s temperature controls

- Lubricate the kiln’s moving parts

- Keep a log of all maintenance performed on the kiln

7. What are the different types of kiln burners and their advantages and disadvantages?

Gas Burners

- Advantages: High efficiency, low emissions, precise temperature control

- Disadvantages: Requires a gas supply, can be expensive to install

Electric Burners

- Advantages: Clean, quiet, precise temperature control

- Disadvantages: High energy consumption, can be expensive to operate

Oil Burners

- Advantages: High efficiency, low emissions, relatively inexpensive to operate

- Disadvantages: Requires a fuel supply, can be noisy

8. How do you install and calibrate a kiln thermocouple?

To install and calibrate a kiln thermocouple, I follow these steps:

- Choose the correct thermocouple for the kiln

- Install the thermocouple in the kiln according to the manufacturer’s instructions

- Connect the thermocouple to the kiln’s temperature controller

- Calibrate the thermocouple using a known temperature source

9. What are the different types of kiln insulation and their properties?

Ceramic Fiber Insulation

- High-temperature resistance

- Low thermal conductivity

- Lightweight and easy to install

Firebrick Insulation

- Very high-temperature resistance

- Durable and long-lasting

- Heavy and difficult to install

Perlite Insulation

- Lightweight and easy to install

- Good thermal insulation properties

- Not as durable as ceramic fiber or firebrick

10. How do you troubleshoot and repair a kiln element?

To troubleshoot and repair a kiln element, I follow these steps:

- Identify the faulty element

- Disconnect the power to the kiln

- Remove the faulty element

- Install a new element

- Reconnect the power to the kiln

- Test the kiln to ensure that the new element is working properly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kiln Mechanics are responsible for the maintenance, repair, and operation of kilns, which are used in various industries to heat and treat materials. Their key job responsibilities include:

1. Maintenance and Repair

Inspect and maintain kilns and associated equipment to ensure optimal performance.

- Identify and diagnose mechanical, electrical, and hydraulic problems.

- Perform repairs, including welding, machining, and electrical troubleshooting.

2. Kiln Operation

Operate kilns according to established procedures to produce high-quality products.

- Monitor kiln temperature, pressure, and other operating parameters.

- Adjust and calibrate kiln controls to optimize performance.

3. Safety and Compliance

Adhere to safety regulations and protocols to ensure a safe work environment.

- Inspect and maintain safety equipment, such as fire extinguishers and emergency shutoff systems.

- Comply with environmental regulations and industry standards.

4. Training and Supervision

Train and supervise new employees or junior mechanics.

- Provide guidance and instruction on kiln maintenance and operation.

- Monitor performance and provide feedback.

Interview Tips

To ace the interview for a Kiln Mechanic position, it is essential to prepare thoroughly. Here are some tips and hacks to help you stand out:

1. Research the Company and Role

Learn about the company’s history, industry, and products/services. Research the specific role you are applying for and its responsibilities.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, including welding, machining, and electrical troubleshooting. Showcase your experience in kiln maintenance and operation.

- Quantify your accomplishments using specific examples.

- Practice describing your skills and experience clearly and concisely.

3. Demonstrate Safety Consciousness

Kiln Mechanics must prioritize safety. Explain your understanding of safety protocols and regulations in the industry.

- Share examples of your safety practices and adherence to standards.

- Discuss your knowledge of emergency procedures and risk assessment.

4. Prepare for Technical Questions

Expect technical questions about kiln maintenance and operation. Be prepared to discuss topics such as:

- Kiln types and their applications

- Temperature and pressure control systems

- Troubleshooting common kiln problems

5. Show Enthusiasm and Motivation

Express your passion for the industry and your desire to contribute to the team. Highlight your willingness to learn and grow.

- Ask thoughtful questions about the company and the role.

- Share your aspirations and professional development plans.

Next Step:

Now that you’re armed with the knowledge of Kiln Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Kiln Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini