Are you gearing up for an interview for a Kiln Operator Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Kiln Operator Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

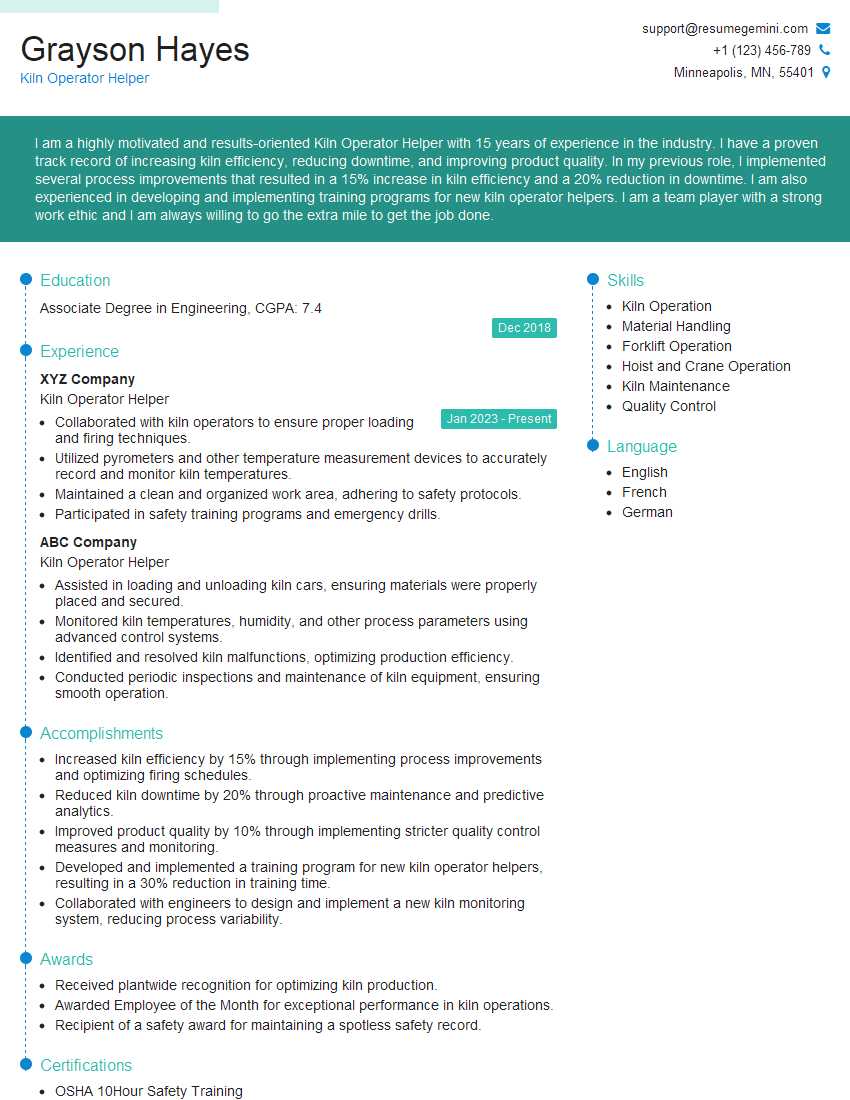

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Operator Helper

1. What are the primary responsibilities of a Kiln Operator Helper?

As a Kiln Operator Helper, I would be primarily responsible for assisting the Kiln Operator in the operation and maintenance of the kiln system. This would include tasks such as:

- Loading and unloading the kiln

- Monitoring and adjusting the kiln’s temperature and atmosphere

- Performing quality checks on the finished product

- Maintaining a clean and organized work area

2. Can you describe the different types of kilns used in the industry?

Batch Kilns

- Loaded and unloaded periodically

- Used for small production runs and specialty products

Tunnel Kilns

- Continuous operation

- Products move through the kiln on a conveyor belt

Shuttle Kilns

- Semi-continuous operation

- Products are loaded onto cars that move in and out of the kiln

3. What are the key safety procedures that must be followed when working in a kiln environment?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator

- Be aware of the potential for high temperatures and take precautions to avoid burns

- Never enter a kiln that is in operation without authorization

- Follow all lockout/tagout procedures when performing maintenance on the kiln

4. How would you troubleshoot a kiln that is not heating evenly?

There are several possible causes for a kiln that is not heating evenly. I would first check the following:

- The thermocouples are properly calibrated and positioned

- The heating elements are functioning properly

- There is no blockage in the airflow

- The kiln is properly insulated

5. What are the different types of materials that can be fired in a kiln?

- Clay

- Ceramics

- Glass

- Metals

6. What is the purpose of a kiln wash?

A kiln wash is a thin layer of material that is applied to the inside of a kiln to protect it from damage caused by heat and chemicals. Kiln washes can also help to improve the heat transfer and reduce the risk of contamination.

7. What are the different types of firing schedules that can be used in a kiln?

- Bisque firing

- Glaze firing

- Raku firing

- Pit firing

8. How would you calculate the amount of glaze needed to cover a given surface area?

To calculate the amount of glaze needed to cover a given surface area, I would use the following formula:

- Amount of glaze (in ounces) = Surface area (in square feet) x Glaze coverage (in square feet per ounce)

9. What are the different types of glazes that can be used in a kiln?

- Clear glazes

- Colored glazes

- Matte glazes

- Glossy glazes

10. What is the difference between a glaze and an underglaze?

A glaze is a thin layer of glass that is applied to the surface of a ceramic piece. An underglaze is a colored glaze that is applied to the ceramic piece before it is glazed. Underglazes are typically used to create patterns or designs on the surface of the ceramic piece.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Kiln Operator Helper assists the Kiln Operator in various tasks related to the operation and maintenance of kilns, which are industrial ovens used in the production of ceramics, cement, and other materials.

1. Assisting with Kiln Operation

The helper’s responsibilities include:

- Monitoring kiln temperatures and other parameters

- Loading and unloading materials into and out of the kiln

- Adjusting burners and other equipment to ensure optimal operation

2. Maintaining Equipment

The helper also assists with:

- Inspecting and cleaning kilns and related equipment

- Performing minor repairs and troubleshooting

- Keeping work areas clean and organized

3. Safety and Compliance

The helper follows established safety procedures and adheres to environmental regulations.

- Wearing appropriate personal protective equipment

- Following lockout/tagout procedures

- Reporting any safety concerns or potential hazards

4. Quality Assurance

The helper supports quality assurance measures by:

- Monitoring product quality and reporting any defects

- Assisting with product testing and sampling

- Maintaining accurate records of kiln operations and product quality

Interview Tips

To prepare for an interview for a Kiln Operator Helper position, candidates can follow these tips:

1. Research the Company and Position

Learn about the company’s products, services, and industry.

- Research the specific job responsibilities and qualifications required.

- Practice answering common interview questions tailored to the position.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in the following areas:

- Kiln operation and maintenance.

- Equipment maintenance and repair.

- Quality assurance and product testing.

3. Demonstrate Safety and Compliance Knowledge

Show your understanding of safety procedures and environmental regulations related to kiln operations.

- Explain your experience with lockout/tagout procedures.

- Discuss your knowledge of personal protective equipment and safe work practices.

4. Prepare for Technical Questions

Practice answering technical questions about kiln operation and equipment maintenance.

- Be prepared to discuss different types of kilns and their uses.

- Explain how you would troubleshoot common kiln problems.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Kiln Operator Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.