Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Kiln Placer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

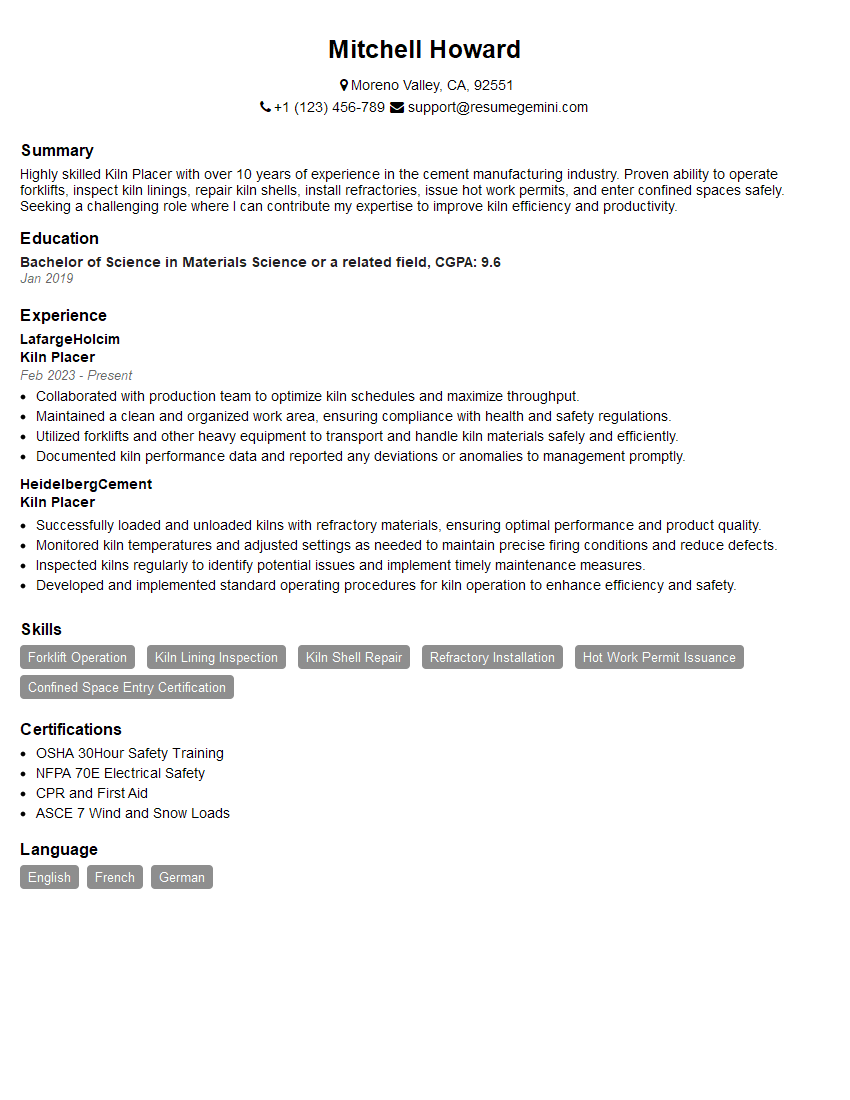

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Placer

1. What are the different types of kilns used in the industry?

- Shuttle kilns

- Tunnel kilns

- Periodic kilns

- Continuous kilns

2. What are the factors to consider when selecting a kiln for a particular application?

- Production capacity

- Product quality

- Energy efficiency

- Capital cost

3. What are the common problems encountered in kiln operation and how can they be solved?

- Temperature uniformity

- Hot spots

- Cracking

- Warpage

4. What are the safety precautions that must be observed when operating a kiln?

- Wear protective clothing

- Use appropriate ventilation

- Never enter a kiln while it is operating

- Be aware of the location of fire extinguishers

5. What are the maintenance procedures that must be followed to keep a kiln in good working order?

- Regular cleaning

- Inspection of heating elements

- Calibration of temperature controllers

- Replacement of worn parts

6. What are the different types of kiln furniture used in the industry?

- Shelves

- Posts

- Saggers

- Batts

7. What are the factors to consider when selecting kiln furniture for a particular application?

- Type of product being fired

- Temperature range of the kiln

- Weight of the product

- Shape of the product

8. What are the common problems encountered with kiln furniture and how can they be solved?

- Cracking

- Warping

- Sticking

- Discoloration

9. What are the safety precautions that must be observed when handling kiln furniture?

- Wear gloves

- Use caution when lifting heavy pieces

- Never place kiln furniture directly on the kiln floor

- Be aware of the location of sharp edges

10. What are the maintenance procedures that must be followed to keep kiln furniture in good working order?

- Regular cleaning

- Inspection for cracks or damage

- Replacement of worn or damaged pieces

- Proper storage when not in use

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Placer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Placer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Kiln Placer, also known as a Kiln Operator or Kiln Setter, plays a critical role in the ceramics or glass production industry.

1. Loading and Unloading Kilns

The primary responsibility of a Kiln Placer is to carefully load and unload kilns with ceramic or glass products. This involves:

- Inspecting products for defects before loading.

- Arranging products inside the kiln to ensure proper airflow and heat distribution.

- Following specific loading patterns to maximize kiln capacity and efficiency.

- Unloading products once the firing process is complete.

2. Operating Kilns

Kiln Placers are responsible for operating kilns, adjusting temperature and airflow controls to achieve the desired results. They need to:

- Monitor kiln temperature and adjust settings accordingly.

- Control airflow to ensure even heat distribution.

- Follow firing schedules and adjust settings as needed.

3. Maintaining Kilns

Maintaining kilns in optimal condition is essential for production efficiency and product quality. Kiln Placers are responsible for:

- Inspecting and cleaning kilns regularly.

- Performing minor repairs and maintenance.

- Identifying potential problems and reporting them to supervisors.

4. Ensuring Safety

Working with kilns involves potential hazards, so Kiln Placers must prioritize safety. Their responsibilities include:

- Wearing appropriate protective gear, such as heat-resistant clothing and gloves.

- Following safety protocols for handling hot and heavy materials.

- Maintaining a clean and organized work area.

Interview Tips

To ace an interview for a Kiln Placer position, candidates should focus on highlighting their technical skills, experience, and understanding of kiln operations.

1. Research the Company and Role

Familiarize yourself with the company, its products, and specific requirements for the Kiln Placer role. Researching the company’s website, LinkedIn page, and industry publications can provide valuable insights.

2. Highlight Relevant Skills and Experience

Emphasize your ability to load and unload kilns, operate kiln controls, and maintain kilns. Quantify your experience whenever possible, using specific examples and metrics.

3. Showcase Safety Knowledge

Demonstrate your understanding of kiln safety, including the use of protective gear, handling heavy materials, and maintaining a safe work environment.

4. Be Prepared to Answer Technical Questions

Interviewers may ask specific questions about kiln operations, such as loading patterns, temperature and airflow control, and troubleshooting techniques. Prepare for these questions by reviewing common firing techniques and kiln maintenance procedures.

5. Ask Thoughtful Questions

Asking well-informed questions shows engagement and interest. Ask about the company’s production processes, the challenges and rewards of being a Kiln Placer, and opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Kiln Placer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Kiln Placer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini