Are you gearing up for a career in Kiln Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Kiln Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

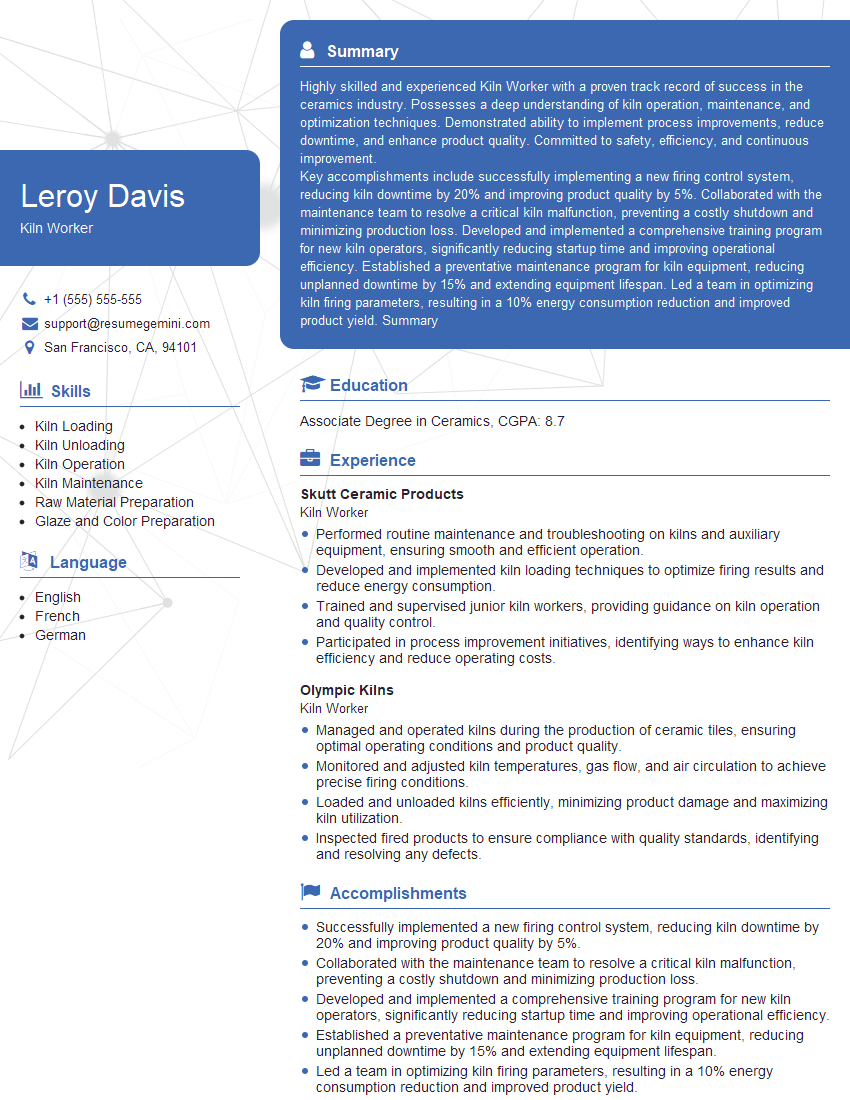

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Worker

1. Explain the process of loading and unloading the kiln?

- Using a kiln car, carefully load the ceramic pieces into the kiln.

- Secure the pieces to prevent movement and damage during firing.

- Once the kiln is loaded, seal the door and check for any leaks or cracks.

- After firing, allow the kiln to cool completely before unloading.

- Carefully unload the fired pieces using the kiln car and inspect them for any defects.

2. What are the different types of kilns and their uses?

Electric Kilns:

- Convenient and easy to operate.

- Ideal for small-scale pottery and hobbyists.

Gas Kilns:

- Provide higher temperatures for more durable ceramics.

- Used in professional studios and for large-scale production.

Wood-Fired Kilns:

- Produce unique and artistic effects with ash and smoke.

- Require specialized knowledge and experience to operate.

Salt Kilns:

- Create distinctive glazed surfaces through the introduction of salt.

- Offer experimental and creative possibilities.

3. How do you ensure the even distribution of heat within the kiln?

To ensure even heat distribution within the kiln:

- Properly stack the pieces in the kiln with adequate spacing.

- Use kiln shelves and supports to create air circulation.

- Calibrate and maintain the kiln’s temperature controls regularly.

- Monitor the kiln’s temperature at multiple points using pyrometers or thermocouples.

- Adjust the kiln settings as needed to achieve uniform heating.

4. What are the safety precautions you take when working with a kiln?

To ensure safety when working with a kiln:

- Wear appropriate protective gear, including gloves, safety glasses, and a mask.

- Inspect the kiln and its components before each use for any damage or malfunctions.

- Follow the manufacturer’s instructions for proper operation and maintenance.

- Keep the work area well-ventilated to prevent exposure to harmful fumes.

- Handle hot kilns and ceramic pieces with care, using kiln tongs or gloves.

5. How do you troubleshoot common kiln problems, such as uneven firing or glaze defects?

To troubleshoot common kiln problems:

- Uneven Firing: Check temperature distribution, spacing of pieces, and calibration of kiln controls.

- Glaze Defects: Examine glaze fit, firing temperature, and cooling rate. Check for glaze contamination or improper application.

- Cracked Pieces: Inspect for overfiring, rapid cooling, or uneven heating. Ensure pieces are properly supported within the kiln.

- Bloating: Determine if clay body is suitable for firing temperature and if pieces are thoroughly dried before firing.

- Reduction Firing Issues: Check kiln atmosphere, fuel mixture, and burner operation. Ensure kiln is properly sealed to prevent oxygen leakage.

6. Describe the different types of glazes and their effects on finished ceramics?

Clear Glazes:

- Transparent or translucent, allowing the clay body to show through.

- Provide a glossy or matte finish, depending on the glaze formula.

Opaques Glazes:

- Non-transparent, concealing the clay body.

- Offer a wide range of colors and textures.

Colored Glazes:

- Contain metal oxides or pigments that produce specific colors.

- Can be transparent, opaque, or semi-transparent.

Textured Glazes:

- Create unique surface effects through the addition of sand, ash, or other materials.

- Can add depth and interest to finished ceramics.

7. What are the different firing techniques used in ceramics, and how do they affect the final product?

Bisque Firing:

- Initial firing at a lower temperature to harden the clay.

- Prepares the pieces for glaze application.

Glaze Firing:

- Firing at a higher temperature to melt and fuse the glaze.

- Creates a protective and decorative surface.

Reduction Firing:

- Firing in an oxygen-reduced atmosphere.

- Produces unique metallic effects and color variations.

Raku Firing:

- Rapid heating and cooling process.

- Creates dramatic crackle patterns and smoky effects.

8. How do you maintain and clean a kiln to ensure its longevity and efficiency?

To maintain and clean a kiln:

- Regularly inspect the kiln elements and coils for damage or wear.

- Clean the kiln shelves and interior with a vacuum cleaner or brush to remove debris.

- Calibrate the kiln’s temperature controls to ensure accurate firing.

- Check the kiln’s insulation for any cracks or gaps that could affect heat distribution.

- Thoroughly clean the kiln after each firing to remove any glaze residue or fumes.

9. Explain the role of clay and water content in the firing process?

Clay and water content play crucial roles in the firing process:

- Clay: Different types of clay have varying properties that influence their behavior during firing.

- Water: Water acts as a binder, giving the clay its plasticity and allowing for shaping.

- Evaporation: During bisque firing, water evaporates from the clay, causing shrinkage and hardening.

- Vitrification: At higher temperatures, the clay undergoes vitrification, where it fuses and becomes more durable.

- Porosity: The amount of water in the clay affects its porosity and absorption after firing.

10. Describe the importance of maintaining a clean and organized work area for a kiln worker?

Maintaining a clean and organized work area is crucial for a kiln worker:

- Safety: Reduces the risk of accidents and injuries.

- Efficiency: Allows for smooth workflow and easy access to materials.

- Quality: Keeps the kiln and tools in good condition, resulting in better firing results.

- Health: Prevents exposure to dust, fumes, and other hazards.

- Professionalism: Demonstrates a commitment to a clean and safe work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kiln Workers are responsible for the operation and maintenance of kilns, which are industrial ovens used for firing and drying ceramic, glass, and other materials.

1. Kiln Operation

Kiln Workers monitor and control the temperature, air flow, and humidity within the kiln using advanced computer systems.

- Load and unload materials into and out of the kiln.

- Adjust and maintain kiln settings to ensure proper firing and drying conditions.

2. Kiln Maintenance

Kiln Workers perform routine maintenance on kilns to ensure optimal performance.

- Clean and inspect kilns to identify any damage or malfunctions.

- Repair and replace kiln components as needed.

3. Quality Control

Kiln Workers monitor the quality of the fired or dried materials and make adjustments to the kiln settings as necessary.

- Inspect finished products for defects or inconsistencies.

- Maintain accurate records of kiln operations and product quality.

4. Safety and Environmental Compliance

Kiln Workers follow safety protocols and adhere to environmental regulations related to kiln operation.

- Wear appropriate personal protective equipment (PPE).

- Follow proper handling and disposal procedures for hazardous materials.

Interview Tips

Preparing for a Kiln Worker interview requires a combination of technical knowledge, attention to detail, and safety awareness. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, culture, and specific kiln operations. Research the job description thoroughly to understand the key responsibilities and required qualifications.

2. Highlight Technical Skills

Emphasize your knowledge of kiln operation, maintenance, and quality control techniques. Provide specific examples of your experience in monitoring and adjusting kiln settings, performing repairs, and inspecting finished products.

3. Demonstrate Safety Consciousness

Kiln operation involves potential hazards. Highlight your commitment to safety by showcasing your understanding of safety protocols, PPE usage, and environmental regulations. Share examples of your safety initiatives or contributions in previous roles.

4. Prepare for Technical Questions

Expect technical questions related to kiln operation, maintenance, and troubleshooting. Be prepared to discuss topics such as temperature control, air flow management, and common kiln malfunctions.

5. Practice Detailed Orientation

Kiln Workers often provide detailed orientations to new employees. Prepare yourself to demonstrate your ability to clearly explain kiln operation procedures, safety protocols, and emergency response plans.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Kiln Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Kiln Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.