Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Kit Planner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

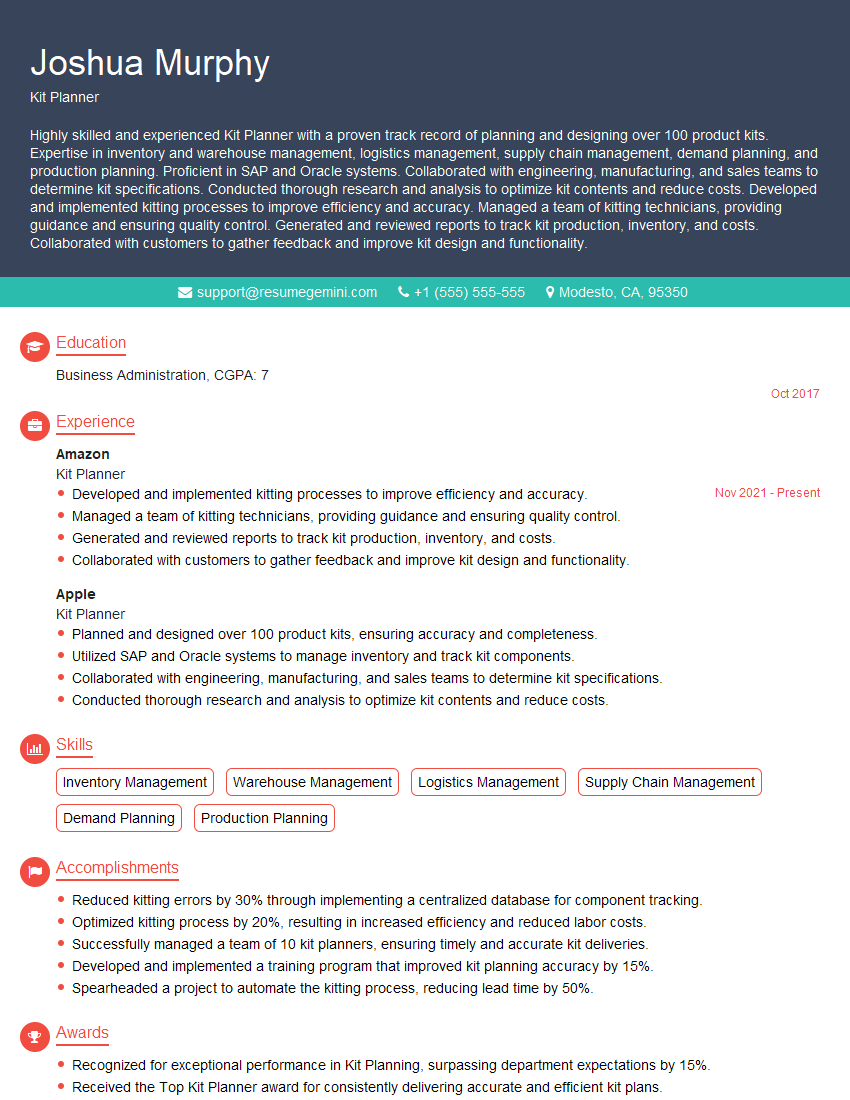

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kit Planner

1. What is the significance of having a detailed kitting plan for a production process?

- Improved inventory management: Kitting plans streamline the storage and allocation of components, reducing inventory waste.

- Enhanced efficiency: By pre-assembling components, kitting eliminates the need for manual retrieval and assembly, saving time and resources.

- Reduced errors: Pre-packaged kits minimize the risk of errors in part selection and assembly, ensuring product quality.

- Optimized production flow: Kitting sequences components in a logical order, ensuring that all necessary parts are available at the right time for assembly.

2. How do you determine the optimal kit size and packaging method for a particular component?

Quality and Protection

- Consider the fragility and sensitivity of the components to determine the necessary packaging materials and protection.

- Ensure that the packaging method prevents damage during handling, storage, and transportation.

Assembly Efficiency

- Determine the appropriate kit size based on the frequency and quantity of component usage during assembly.

- Design the kit to enable easy handling and accessibility at the point of assembly.

Cost-Effectiveness

- Evaluate the cost of materials, packaging, and labor associated with different kitting methods.

- Optimize the kit size to minimize waste and excess inventory while meeting production demand.

3. How do you manage the transition from one kitting plan to another when there is a change in product design or manufacturing process?

- Conduct a thorough review of the changes and assess their impact on the kitting plan.

- Develop a detailed transition plan outlining the necessary adjustments to packaging, kitting sequence, and inventory management.

- Communicate the transition plan clearly to all stakeholders involved in kitting and assembly.

- Implement the transition plan in a controlled and phased manner to avoid disruptions to production.

- Monitor the transition process closely and make necessary adjustments to ensure a smooth and successful switch.

4. What inventory management techniques do you employ to ensure the availability of components for kitting and assembly?

- Just-in-Time (JIT) Inventory: Maintain minimal inventory levels and replenish components as needed based on production demand.

- Kanban System: Use visual signals to indicate when components need to be replenished, ensuring timely delivery to kitting operations.

- Safety Stock: Keep a buffer stock of critical components to mitigate unexpected demand fluctuations and avoid production delays.

- Material Requirements Planning (MRP): Forecast component requirements based on production schedules and plan for timely procurement.

- Vendor Managed Inventory (VMI): Collaborate with suppliers to manage component inventory levels and optimize delivery schedules.

5. How do you collaborate with other departments, such as engineering, production, and quality control, to ensure the alignment of kitting plans with overall production goals?

- Regular Communication: Establish open communication channels with cross-functional teams to exchange information and discuss kitting requirements.

- Cross-Departmental Meetings: Hold periodic meetings to review kitting plans, identify potential issues, and coordinate efforts.

- Design Reviews: Participate in design reviews to understand component specifications and provide input on kitting feasibility.

- Production Plan Coordination: Collaborate with production to ensure that kitting plans align with production schedules and capacity.

- Quality Inspections: Work closely with quality control to establish kitting standards and ensure compliance with quality protocols.

6. How do you stay up-to-date with the latest trends and best practices in kitting and inventory management?

- Industry Events and Webinars: Attend industry conferences, workshops, and webinars to learn about emerging technologies and methodologies.

- Professional Development: Pursue professional certifications or training programs to enhance knowledge and skills in kitting and inventory management.

- Online Research: Regularly read industry publications, websites, and blogs to stay informed about the latest advancements in the field.

- Collaboration with Experts: Network with other professionals in kitting and inventory management to exchange ideas and learn from their experiences.

- Benchmarking: Conduct industry benchmarking studies to identify areas for improvement and adopt best practices from leading organizations.

7. How do you handle unexpected changes or disruptions that may impact kitting operations?

- Assessment and Communication: Quickly assess the impact of the disruption and communicate it to relevant stakeholders.

- Contingency Planning: Develop contingency plans outlining alternative kitting strategies to mitigate potential disruptions.

- Inventory Adjustments: Adjust inventory levels and kitting schedules to adapt to changing demand or supply constraints.

- Supplier Collaboration: Work closely with suppliers to identify alternative sources or expedite deliveries if necessary.

- Optimization: Continuously monitor kitting operations and identify areas for improvement to enhance resilience and reduce the impact of disruptions.

8. What metrics do you use to measure the effectiveness of your kitting plans and inventory management practices?

- Kitting Accuracy: Measure the percentage of kits that are assembled correctly and meet quality standards.

- Inventory Turnover: Calculate the ratio of goods sold to average inventory to assess the efficiency of inventory management.

- Lead Time Reduction: Track the time taken from kit preparation to assembly to identify areas for improvement and reduce production lead times.

- Cost Savings: Evaluate the cost savings achieved through optimized kitting and inventory management practices.

- Customer Satisfaction: Monitor customer satisfaction levels to ensure that kitting and inventory management contribute to improved product quality and delivery performance.

9. Describe a situation where you successfully implemented a kitting solution that significantly improved production efficiency.

- Problem Identification: Outline the inefficiencies encountered in the existing assembly process.

- Kitting Plan Development: Explain how you designed and implemented a customized kitting plan.

- Implementation and Results: Describe the steps taken to implement the kitting plan and quantify the positive impact it had on production efficiency.

- Challenges and Mitigation: Discuss any challenges faced during implementation and how you overcame them.

- Key Learnings: Summarize the valuable lessons learned from the successful implementation.

10. What is your approach to continuous improvement in kitting and inventory management processes?

- Regular Review and Analysis: Conduct regular reviews of kitting plans and inventory management practices to identify areas for improvement.

- Process Mapping and Optimization: Map kitting and inventory management processes to identify bottlenecks and opportunities for streamlining.

- Employee Feedback: Encourage feedback from team members involved in kitting and inventory management to gather valuable insights.

- Technology Adoption: Explore the use of technology solutions such as inventory management software and automation to enhance efficiency.

- Benchmarking and Knowledge Sharing: Benchmark against industry best practices and share knowledge with other organizations to continuously improve practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kit Planner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kit Planner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Kit Planner is responsible for effectively managing the planning, development, and implementation of kitting projects. This includes working closely with project stakeholders and cross-functional teams to identify kitting opportunities, develop kitting plans, and procure necessary materials.

1. Kitting Planning and Development

- Develops detailed kitting plans that optimize kit contents, minimize assembly time, and meet quality standards.

- Collaborates with product design, engineering, and manufacturing teams to create kitting specifications and identify kitting opportunities.

- Determines kit size, packaging, and shipping requirements based on product characteristics and customer needs.

2. Supplier Management

- Identifies and qualifies supplier for kitting components, ensuring quality and cost effectiveness.

- Manages vendor relationships, negotiates prices, and monitors supplier performance.

- Develops and implements supplier quality assurance programs to ensure component compliance.

3. Inventory Management

- Maintains inventory of kitting components, ensuring timely availability and minimizing waste.

- Performs inventory forecasts and replenishment planning to optimize inventory levels and prevent stockouts.

- Implements inventory control systems and procedures to reduce inventory costs and improve efficiency.

4. Project Management

- Provides project management oversight for kitting projects, ensuring timely completion and budget adherence.

- Monitors project progress and makes adjustments to ensure efficient execution.

- Collaborates with cross-functional teams to resolve issues and achieve project goals.

Interview Tips

Preparing for an interview for a Kit Planner position requires thorough research and self-assessment. Here are some tips to help you succeed:

1. Research the Company and Industry

- Learn about the company’s mission, values, and products/services.

- Understand the company’s approach to kitting and its relevance to your skills and experience.

- Stay up-to-date with industry trends and best practices in kitting.

2. Highlight Relevant Experience and Skills

- Emphasize your experience in kitting planning, supplier management, inventory control, and project management.

- Provide specific examples of how you have implemented kitting solutions that improved efficiency, reduced costs, or enhanced customer satisfaction.

- Showcase your ability to manage complex projects, work collaboratively, and resolve problems effectively.

3. Practice Common Interview Questions

- Prepare for questions related to your kitting experience, including kit planning, supplier selection, inventory management, and project management.

- Practice answering questions about your understanding of the company and its approach to kitting.

- Prepare questions for the interviewer to demonstrate your interest and engagement.

4. Seek Feedback and Improve

- After the interview, reflect on your performance and identify areas for improvement.

- Ask for feedback from the interviewer if possible to gain insights into your strengths and weaknesses.

- Use the feedback to refine your preparation and enhance your interview skills for future opportunities.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Kit Planner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.