Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Knife Blade Polisher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Knife Blade Polisher so you can tailor your answers to impress potential employers.

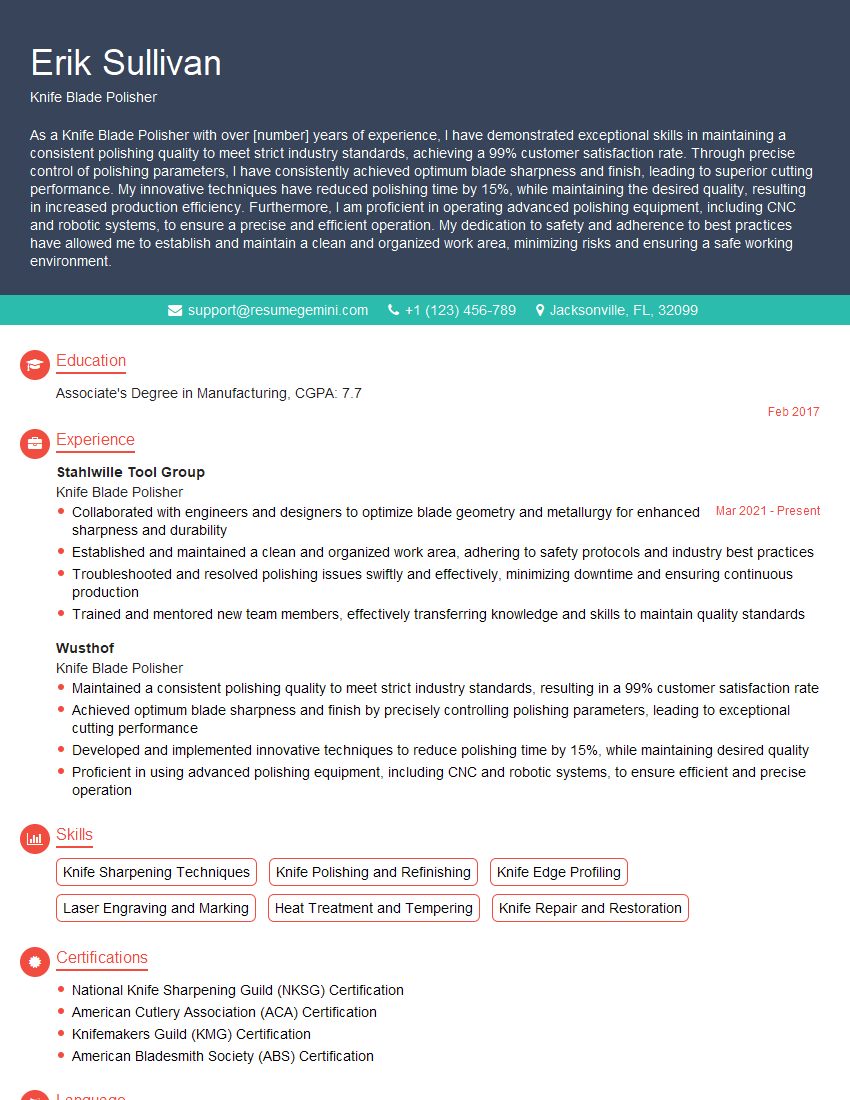

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knife Blade Polisher

1. What are the different types of knife blade steels and their properties?

- Carbon Steel: High carbon content, hard, good edge retention, prone to rust.

- Stainless Steel: Corrosion-resistant, lower carbon content, less hard, easier to sharpen.

- Alloy Steel: Combination of carbon and alloying elements, balanced properties.

- Damascus Steel: Pattern-welded steel, strong, durable, decorative.

- Ceramic Steel: Made from zirconium oxide, extremely hard, brittle, retains sharpness for longer.

2. What is the proper technique for sharpening a knife blade?

Grindstone Method

- Use a coarse grindstone to remove excess metal and establish an angle.

- Switch to a fine grindstone to refine the edge.

- Maintain a consistent angle throughout the process.

Honing Method

- Use a honing steel to realign the blade’s edge.

- Hold the steel perpendicular to the blade and draw the blade gently across it.

3. How do you determine the correct angle for sharpening a blade?

- Consider the type of knife and its intended use.

- Use an angle guide or a protractor to measure the existing angle.

- Start with a slightly lower angle for softer steels and higher angle for harder steels.

- Experiment with different angles to find the optimal sharpness for the specific blade.

4. What are the common mistakes made when polishing a knife blade?

- Using too much pressure, which can damage the blade.

- Polishing against the grain, which creates scratches.

- Not cleaning the blade properly before polishing.

- Over-polishing, which can remove too much material and weaken the blade.

5. How do you handle a damaged or chipped knife blade?

Minor Damage

- Use a fine grindstone to remove the damaged area.

- Sharpen the blade as usual.

Major Damage

- May require re-forging or grinding the blade.

- Consult with a professional knife maker or machinist for more complex repairs.

6. What is the difference between polishing and buffing a knife blade?

- Polishing removes scratches and creates a smooth surface.

- Buffing creates a mirror-like finish and removes any remaining imperfections.

- Polishers use abrasive materials, while buffers use soft materials like cotton or felt.

7. What equipment and materials do you need for knife blade polishing?

- Grindstones (coarse and fine)

- Honing steel

- Polishing wheel or buffer

- Abrasive compounds (polishing paste)

- Safety goggles and gloves

- Work bench or vise

8. How do you maintain the sharpness of a knife blade?

- Regular honing with a honing steel.

- Sharpening with a grindstone or whetstone when necessary.

- Storing knives in a dry place to prevent rust.

- Avoiding cutting hard materials or using knives for unintended purposes.

9. What are the potential hazards of knife blade polishing and how do you mitigate them?

- Sharp edges: Use cut-resistant gloves and handle knives carefully.

- Abrasive dust: Wear a mask and work in a well-ventilated area.

- Electrical hazards: Ensure equipment is properly grounded and inspect cords regularly.

- Fire risk: Keep flammable materials away from polishing area.

10. Do you have experience with different types of knife blades, such as chef’s knives, hunting knives, or pocket knives?

- Yes, I have worked with various knife blades, including chef’s knives for professional kitchens, hunting knives for outdoor use, and pocket knives for everyday carry.

- I am familiar with the specific requirements and challenges of polishing different blade geometries and materials.

- My experience allows me to achieve optimal sharpness and aesthetics for a wide range of knife blades.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knife Blade Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knife Blade Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knife Blade Polishers holds the responsibility of sharpening, honing, and polishing knife blades through the use of various tools and techniques. They ensure the blades meet the required sharpness, smoothness, and aesthetics as per the company’s standards. The key job responsibilities of a Knife Blade Polisher include:

1. Inspecting and Assessing Blades

Examining knife blades to determine their condition, identifying any damage, dullness, or imperfections that require attention.

2. Sharpening and Honing Blades

Utilizing grinding wheels, stones, or honing rods to restore the blade’s sharpness and remove any nicks or burrs. Honing aligns the blade’s edge for improved sharpness.

3. Polishing Blades

Applying polishing compounds and using buffing wheels to create a smooth, mirror-like finish on the blade’s surface.

4. Maintaining Equipment

Ensuring the proper functioning of grinding machines, honing rods, and other equipment used in the polishing process. Conducting regular maintenance and cleaning to prevent breakdowns.

5. Quality Control

Inspecting finished blades to ensure they meet the specified quality standards. Identifying and correcting any defects or inconsistencies.

6. Following Safety Protocols

Adhering to established safety guidelines while operating machinery, handling sharp blades, and using chemicals.

Interview Tips

Preparing thoroughly for a Knife Blade Polisher interview is crucial to showcasing your skills and increasing your chances of success. Here are some helpful interview tips:

1. Research the Company and Role

Learn about the company’s history, culture, and the specific requirements of the Knife Blade Polisher position. This demonstrates your interest and understanding of the organization.

2. Practice Your Skills

If possible, practice sharpening and polishing knife blades beforehand. This hands-on experience will boost your confidence and enable you to provide specific examples of your abilities.

3. Emphasize Your Attention to Detail

Highlight your meticulous nature and ability to work precisely. Knife Blade Polishers must possess a keen eye for detail to ensure the blades meet the desired sharpness and finish.

4. Showcase Your Safety Knowledge

Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment. This is a critical aspect of knife blade polishing, as working with sharp blades requires utmost caution.

5. Prepare Questions

Asking thoughtful questions during the interview demonstrates your engagement and interest in the position. Prepare questions about the company’s quality standards, the equipment used, or any opportunities for professional development.

6. Dress Professionally

First impressions matter. Dress appropriately for the interview, reflecting the professional nature of the role and the company’s culture.

7. Be Enthusiastic and Positive

Convey your passion for working with knives and your eagerness to contribute to the company’s success. A positive attitude and enthusiasm can make a memorable impression on the interviewers.

Next Step:

Now that you’re armed with the knowledge of Knife Blade Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Knife Blade Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini