Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Knife Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

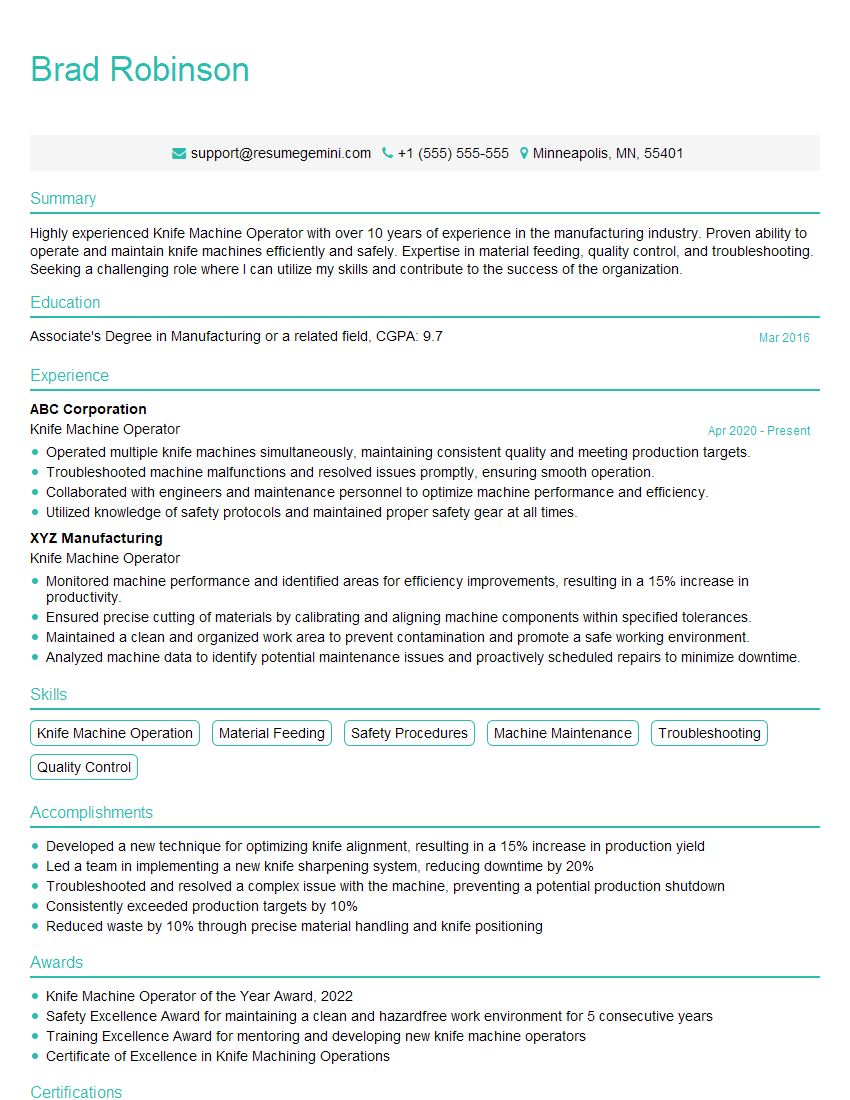

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knife Machine Operator

1. Explain the different types of knives used in a knife machine and their applications?

- Circular Knives(Straight): Used for straight cutting operations, such as cutting paper or film.

- Circular Knives(Perforated): Create perforated cuts, commonly used in packaging or food processing.

- Slitting Knives: Used for precise and narrow cuts, often employed in converting operations.

- Shear Blades: Designed for shearing or trimming materials, used in various industries.

- Guillotine Knives: Heavy-duty knives utilized for cutting thick or rigid materials.

2. Describe the process of setting up and calibrating a knife machine?

Knife Mounting and Adjustment

- Secure the appropriate knife on the machine spindle.

- Adjust the knife holder and bearings for optimal alignment.

- Set the knife gap and pressure to ensure precise cuts.

Calibration and Testing

- Use a calibration tool to verify knife alignment and accuracy.

- Run test cuts on scrap material to ensure proper operation.

- Make necessary adjustments based on test results.

3. What are the common safety precautions to observe when operating a knife machine?

- Wear appropriate safety gear, including gloves and eye protection.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Never attempt to operate the machine with loose clothing or jewelry.

- Keep the work area clean and free of debris to prevent accidents.

- Follow established lockout/tagout procedures before performing maintenance or repairs.

4. Explain the importance of knife maintenance and how to perform basic maintenance tasks?

- Regular sharpening and honing to maintain optimal cutting performance.

- Cleaning and lubrication of the machine and knife components to prevent wear and tear.

- Replacing worn or damaged knives promptly to ensure safety and precision.

- Inspecting the machine for any loose parts, vibrations, or unusual noises.

5. Describe the different types of materials that can be processed using a knife machine?

- Paper and paperboard

- Plastic films and sheets

- Textiles and fabrics

- Leather and rubber

- Composite materials

6. Explain the role of feed systems in a knife machine and their different types?

- Rotary Feed Systems: Continuous feeding of material through rotating rollers.

- Sheet Feed Systems: Handling individual sheets of material, ensuring precise alignment.

- Conveyor Feed Systems: Transporting materials on a conveyor belt, allowing for variable feeding rates.

- Advance Feed Systems: Moving materials through the machine in increments, enabling accurate cutting.

7. Describe the different types of output systems used in knife machines?

- Stackers: Collecting and stacking cut materials in an organized manner.

- Conveyors: Transporting cut materials away from the machine for further processing.

- Rewinders: Rolling up cut materials into rolls, often used for films or fabrics.

- Trimmers: Removing excess material from the edges of cut pieces, ensuring clean and finished edges.

8. Explain the importance of quality control in knife machine operations?

- Ensuring the accuracy and precision of cuts to meet customer specifications.

- Minimizing defects and waste, reducing production costs.

- Maintaining a consistent level of quality, enhancing customer satisfaction.

- Complying with industry standards and regulations.

9. Describe the different types of automation used in knife machines and their advantages?

- Automatic Knife Changing: Replacing knives without manual intervention, reducing downtime.

- Automatic Feed Control: Optimizing feed rates for different materials, improving efficiency.

- Vision Systems: Inspecting cut materials for defects, ensuring quality.

- Robotics: Integrating robotic arms for material handling, increasing productivity.

10. Explain the importance of training and certification for knife machine operators?

- Ensuring operators are proficient in safe and efficient machine operation.

- Minimizing accidents and reducing the risk of injuries.

- Enhancing productivity and optimizing machine performance.

- Meeting industry standards and regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knife Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knife Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knife Machine Operators are responsible for overseeing the operation of knife machines, which are used to cut, trim, and shape materials such as fabric, paper, and metal.

1. Machine Operation

Operate knife machines according to established procedures, ensuring that materials are cut, trimmed, and shaped to specifications.

- Set up and adjust machines

- Load and unload materials

- Monitor machine operation

2. Quality Control

Inspect products to ensure that they meet quality standards, including dimensions, tolerances, and surface finish.

- Identify and correct defects

- Maintain records of quality control checks

3. Maintenance

Perform basic maintenance on machines, including cleaning, lubrication, and minor repairs.

- Troubleshoot and resolve minor malfunctions

- Report major problems to supervisors

4. Safety

Follow all safety protocols and procedures, ensuring a safe work environment for themselves and others.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

Interview Tips

Interviewing for a Knife Machine Operator position can be challenging. Here are some tips to help you ace the interview.

1. Research the Company and the Position

Take some time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture and the specific skills and experience they are looking for.

- Visit the company website

- Read industry news and articles

- Talk to people in your network who work in the industry

2. Practice Your Answers

Prepare for common interview questions and practice your answers. This will help you feel more confident and prepared during the interview.

- Tell me about your experience operating knife machines.

- What are your strengths and weaknesses as a Knife Machine Operator?

- Why are you interested in working for this company?

3. Be Enthusiastic and Positive

Show the interviewer that you are excited about the opportunity to work as a Knife Machine Operator. Be positive and enthusiastic about your skills and experience.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be respectful of the interviewer’s time

4. Follow Up

After the interview, send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and thank the interviewer for their time.

- Send a thank-you note within 24 hours of the interview

- Reiterate your interest in the position

- Thank the interviewer for their time

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Knife Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.