Are you gearing up for an interview for a Knife Setter Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Knife Setter Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

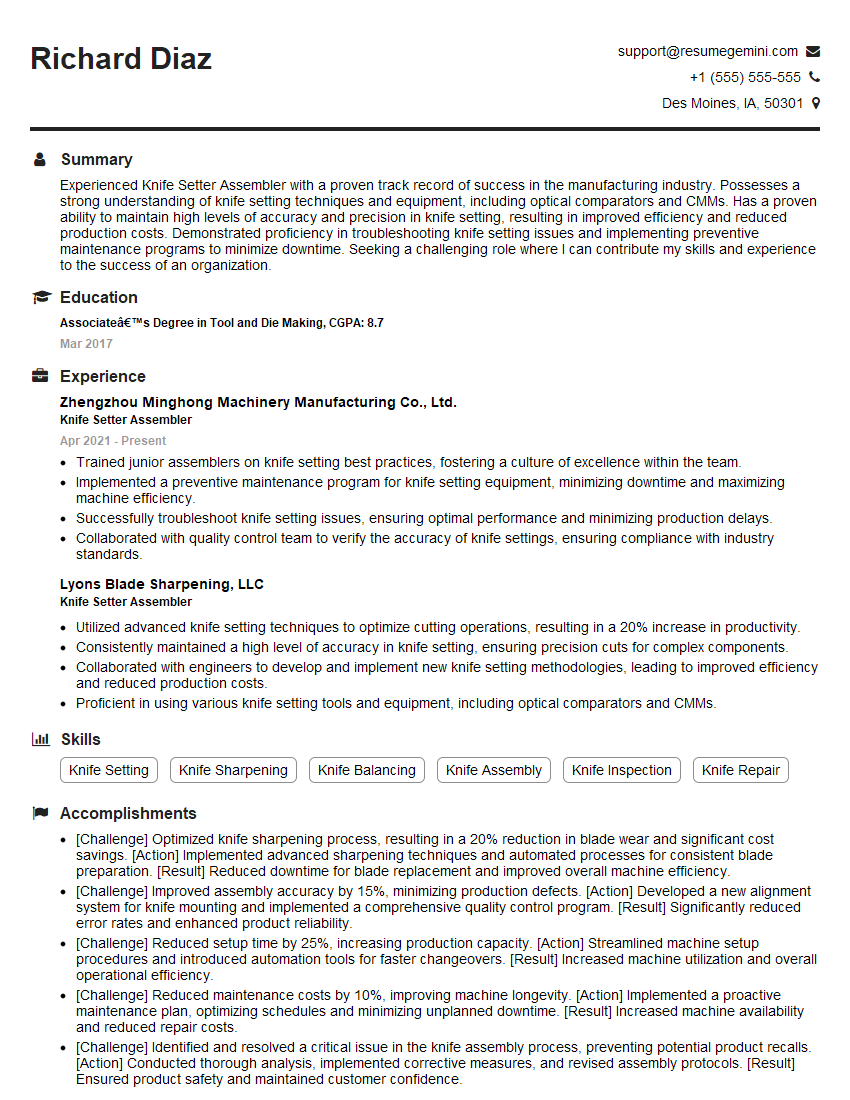

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knife Setter Assembler

1. What are the key responsibilities of a Knife Setter Assembler?

- Set up and adjust knives on assembly machines to ensure precise cutting and assembly operations.

- Inspect and maintain knives, ensuring they are sharp and free from defects.

- Troubleshoot and resolve assembly issues related to knives or cutting operations.

2. Describe the various types of knives used in assembly operations and their applications.

Rotary Knives

- Used for cutting materials in a circular motion, such as paper, plastic, and textiles.

Shear Blades

- Used for cutting materials by applying force along a straight line, such as metal, wood, and rubber.

Slitting Knives

- Used for cutting narrow strips of material, such as paper, film, and foil.

Guillotine Blades

- Used for cutting materials by applying pressure from above, such as paper, cardboard, and plastic.

3. Explain the process of setting up a knife on an assembly machine.

- Mount the knife onto the machine’s knife holder.

- Adjust the knife’s position and angle to ensure precise cutting.

- Secure the knife in place using appropriate hardware.

- Test the knife’s operation to verify its accuracy and performance.

4. What are the safety precautions to be observed when working with knives in an assembly environment?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and cut-resistant clothing.

- Keep knives sharp to prevent slipping and accidents.

- Use proper handling techniques and never point the knife towards yourself or others.

- Store knives securely in designated areas when not in use.

5. Describe the troubleshooting steps you would take if an assembly machine is experiencing cutting issues.

- Check if the knife is sharp and free from defects.

- Inspect the machine’s settings and adjustments, ensuring they are correct for the material being cut.

- Examine the material’s properties, such as thickness and density, to determine if they are compatible with the knife’s cutting capabilities.

- Check the machine’s sensors and controls to ensure they are functioning properly.

6. What are the quality control measures you would implement to ensure the accuracy and precision of knife-related assembly operations?

- Establish clear specifications for knife settings and adjustments.

- Regularly inspect knives for wear and damage.

- Conduct periodic test cuts to verify the accuracy of the cutting operations.

- Train operators on proper knife setting and maintenance procedures.

7. Describe your experience in working with different types of assembly machines and their knife-related components.

- Experience working with CNC punching machines and their rotary knives for cutting metal sheets.

- Hands-on experience in setting up and maintaining shear blades on assembly lines for cutting plastic components.

- Proficient in troubleshooting and resolving knife-related issues on automated packaging machines.

8. What is your understanding of the industry standards and best practices for knife setting and assembly operations?

- Familiar with ANSI and OSHA safety regulations for knife handling and assembly operations.

- Stay up-to-date on industry best practices, including knife sharpening techniques and preventive maintenance procedures.

- Attend industry workshops and training programs to enhance knowledge and skills.

9. Describe a situation where you successfully resolved a complex knife-related issue on an assembly line.

- Encountered a problem where knives were prematurely dulling, causing uneven cuts and production delays.

- Investigated the issue, identified that the material being cut had abrasive properties that were wearing down the knives.

- Recommended a different knife material with higher wear resistance, which resolved the problem and improved production efficiency.

10. What are your expectations and goals for this role as a Knife Setter Assembler?

- Contribute to the smooth and efficient operation of assembly lines by ensuring optimal knife performance.

- Utilize my knowledge and skills to troubleshoot and resolve knife-related issues promptly.

- Continuously seek opportunities to improve knife setting and assembly processes, enhancing productivity and product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knife Setter Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knife Setter Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knife Setter Assemblers are responsible for a variety of tasks that are essential to the production of knives. These tasks include identifying knives, setting up machines to cut and assemble knives, inspecting knives for quality, and troubleshooting and repairing machines.

1. Identifying Knives

Knife Setter Assemblers must be able to identify different types of knives. This includes knowing the different parts of a knife, such as the blade, handle, and guard. They must also be able to identify the different types of materials used to make knives, such as steel, stainless steel, and titanium.

2. Setting Up Machines to Cut and Assemble Knives

Knife Setter Assemblers must be able to set up machines to cut and assemble knives. This includes setting the correct parameters on the machine, such as the speed and feed rate. They must also be able to troubleshoot and repair machines if they malfunction.

3. Inspecting Knives for Quality

Knife Setter Assemblers must be able to inspect knives for quality. This includes checking the knives for defects, such as cracks, chips, and burrs. They must also be able to check the knives for sharpness and balance.

4. Troubleshooting and Repairing Machines

Knife Setter Assemblers must be able to troubleshoot and repair machines. This includes identifying the problem with the machine and then taking steps to repair it. They must also be able to replace parts on the machine if necessary.

Interview Tips

Preparing for an interview for a Knife Setter Assembler position can be a challenge. However, by following these tips, you can increase your chances of success.

1. Research the Company

Before you go to your interview, take some time to research the company. This will help you understand the company’s culture, values, and products. You should also learn about the company’s history, financial performance, and recent news. This information will help you answer questions about the company during your interview.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked during your interview. These questions include “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

During your interview, you will be asked about your experience. Be prepared to talk about your skills, knowledge, and accomplishments. You should also be prepared to discuss your work history, including your previous jobs and responsibilities.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are a hard worker. You should also be respectful of the interviewer’s time and be prepared to answer their questions honestly and thoroughly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Knife Setter Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.