Feeling lost in a sea of interview questions? Landed that dream interview for Knitted Goods Shaper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Knitted Goods Shaper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

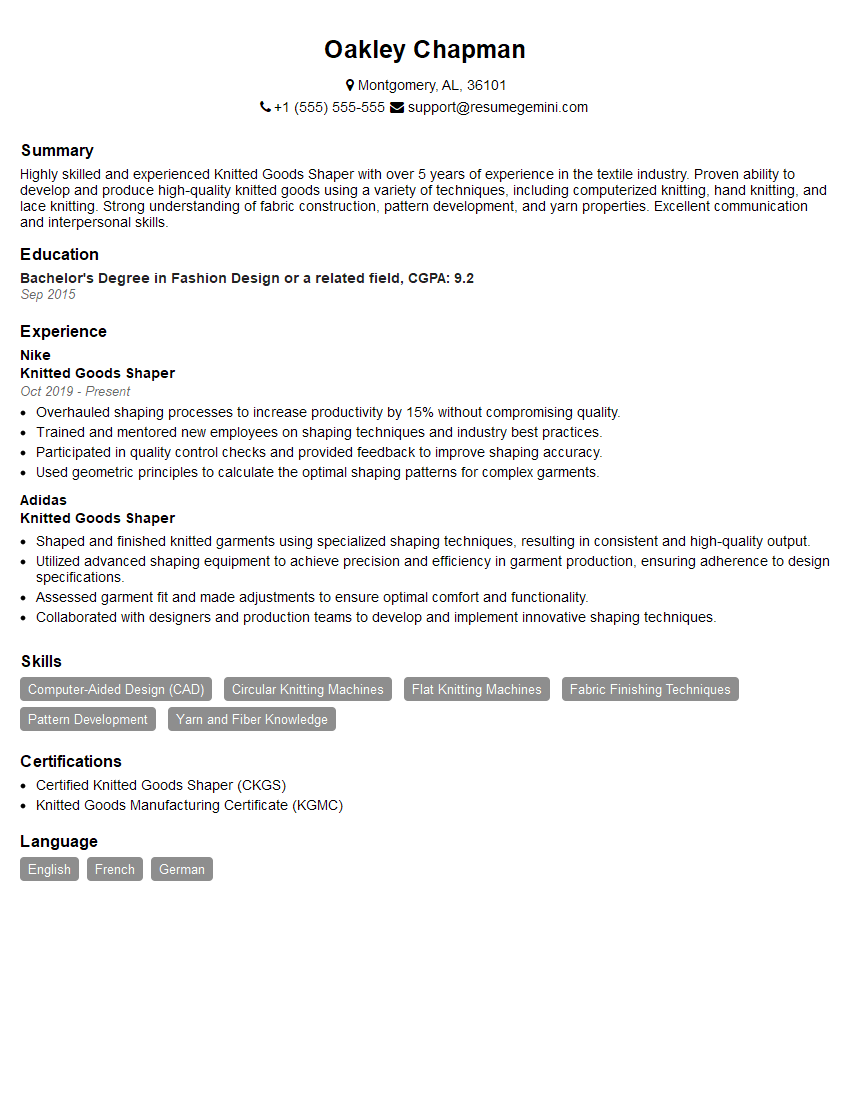

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knitted Goods Shaper

1. What are the different types of shaping techniques used in knitted goods manufacturing?

– Tuck Stitch: Creating a raised or textured effect by selectively tucking stitches under the previous row. – Transfer Stitch: Moving stitches from one needle to another to create cable patterns or other designs. – Intarsia and Fair Isle: Knitting with multiple colors in a single row to create patterns. – Slip Stitch Ribbing: Using slipped stitches to create a stretchy and ribbed fabric. – Increases and Decreases: Adding or removing stitches to shape the fabric, creating curves, angles, or tapered sections.

2. Explain the process of pattern grading for knitted garments.

Grading by Percentage

- Calculate the difference between the two sizes in each measurement.

- Multiply the difference by a grading percentage to determine the amount to add or remove.

Grading by CAD Software

- Input the original pattern measurements into a CAD program.

- Use the program’s grading tools to automatically adjust the pattern for different sizes.

3. What are the key quality control measures for knitted goods shaping?

- Checking for correct stitch count and pattern execution.

- Measuring and inspecting the finished garment to ensure it meets specifications.

- Identifying and correcting any defects in the shaping process.

- Maintaining accurate records of inspections and quality control measures.

4. Describe the use of different knitting machines for shaping purposes.

- Single Needle Cylinder Knitting Machines: Can produce basic shapes with tuck stitch.

- Double Needle Cylinder Knitting Machines: Allow for more complex shaping using transfer stitch.

- Flat Knitting Machines: Offer greater flexibility and control for intricate shaping techniques.

- Circular Knitting Machines: Used to create round shapes, such as sweaters and hats.

5. How do you troubleshoot common shaping defects in knitted fabrics?

- Missed Stitches: Adjust the tension or use a different needle size.

- Uneven Shaping: Check the pattern grading or adjust the knitting machine settings.

- Puckering or Stretching: Adjust the tension or use a different yarn weight.

- Incorrect Cable Patterns: Ensure the correct number of stitches are transferred and twisted in the correct direction.

6. What are the latest trends in knitted goods shaping techniques?

- 3D Knitting: Creating complex three-dimensional shapes.

- Jacquard Knitting: Using multiple yarns to create intricate patterns.

- Seamless Knitting: Knitting the entire garment as a single piece without seams.

- Digital Knitting: Using computer-aided design to create and control knitting patterns.

7. How do you ensure accuracy and precision when shaping knitted goods?

- Use high-quality knitting machines with accurate tension control.

- Follow pattern instructions meticulously and measure regularly.

- Conduct thorough quality control checks before and after shaping.

- Maintain detailed records of knitting settings and adjustments.

8. What are the key characteristics of well-shaped knitted garments?

- Precise and symmetrical shaping.

- Even stitch count and tension throughout.

- Smooth and consistent transitions between shapes.

- No puckering, stretching, or missed stitches.

- Garment fits comfortably and complements the wearer’s body shape.

9. How do you determine the appropriate shaping technique for a particular garment design?

- Analyze the garment’s design and identify the desired shapes.

- Consider the type of fabric and yarn used.

- Select the knitting machine and techniques that will produce the best results.

- Create a sample to test the shaping technique before producing the full garment.

10. What is your approach to staying updated on the latest advancements in knitted goods shaping?

- Attend industry conferences and trade shows.

- Read industry publications and articles.

- Network with other professionals in the field.

- Experiment with new techniques and materials.

- Continuously seek opportunities for professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knitted Goods Shaper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knitted Goods Shaper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knitted Goods Shaper is responsible for shaping knitted goods to meet the desired specifications. This includes duties such as inspecting knitted goods for defects, measuring and cutting the goods, and using specialized equipment to shape the goods. The key responsibilities of a Knitted Goods Shaper include:

1. Inspecting Knitted Goods

The Knitted Goods Shaper is responsible for inspecting knitted goods to ensure that they meet the desired quality standards. This includes checking for defects such as holes, tears, or uneven stitching. The Shaper must also verify that the dimensions of the goods are correct and that the goods are free of any other defects.

2. Measuring and Cutting Knitted Goods

The Knitted Goods Shaper is responsible for measuring and cutting the goods to the desired specifications. This involves using a variety of tools and equipment, such as rulers, scissors, and cutting machines. The Shaper must be able to accurately measure and cut the goods to ensure that they fit properly and meet the customer’s requirements.

3. Shaping Knitted Goods

The Knitted Goods Shaper is responsible for using specialized equipment to shape the goods. This includes using machines such as steamers, presses, and blocking boards. The Shaper must be able to use these machines safely and efficiently to achieve the desired shape and finish for the goods.

4. Quality Control

The Knitted Goods Shaper is responsible for ensuring that the finished goods meet the desired quality standards. This includes checking the goods for any defects and ensuring that they are properly packaged and shipped.

Interview Tips

Following are some tips to help you ace your Knitted Goods Shaper interview:

1. Research the Company and Position

Take the time to learn about the company and the specific position you are applying for. This will help you to better understand the company’s culture and the requirements of the job. You can research the company’s website, social media pages, and Glassdoor reviews to get a better understanding of the company.

2. Practice Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Highlight Your Relevant Skills and Experience

Be sure to highlight your relevant skills and experience in your interview. This includes any experience you have in the textile industry, as well as any skills that are relevant to the position you are applying for, such as sewing, cutting, or shaping.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It also gives you an opportunity to learn more about the company and the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Knitted Goods Shaper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Knitted Goods Shaper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.