Feeling lost in a sea of interview questions? Landed that dream interview for Knitting Machine Fixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Knitting Machine Fixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

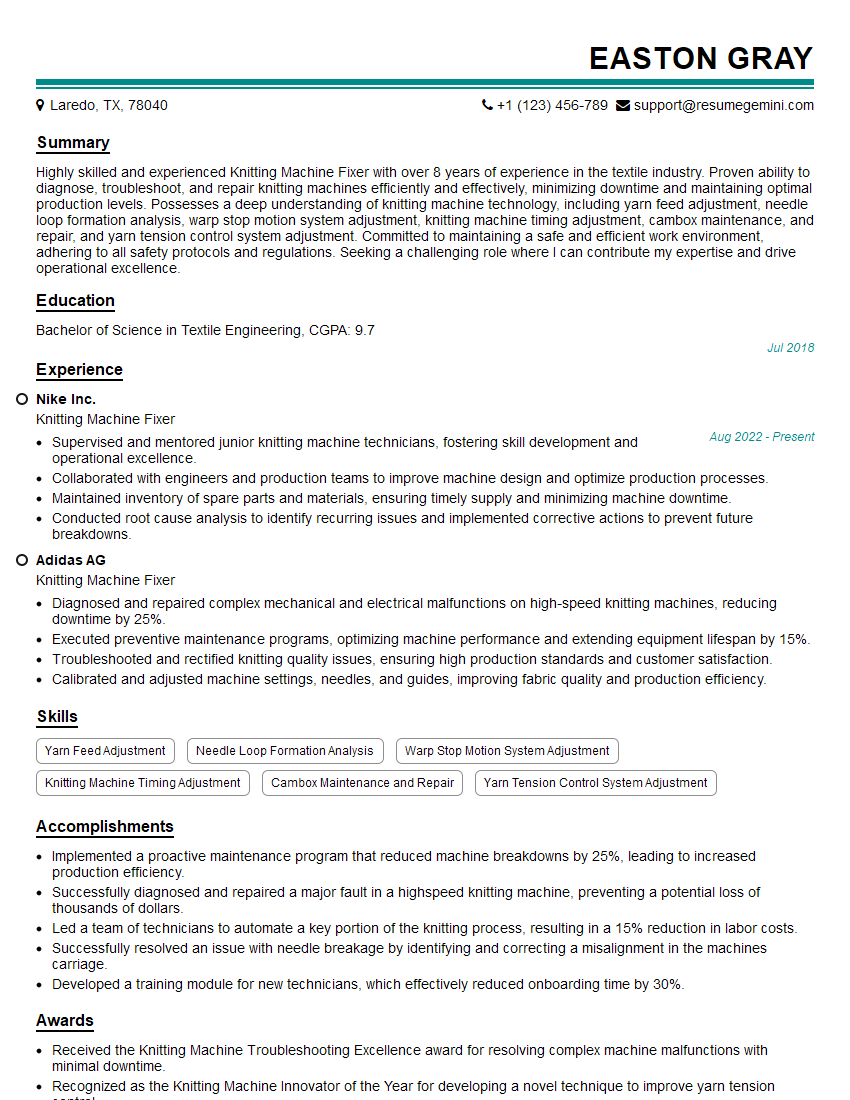

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knitting Machine Fixer

1. What are the key components of a knitting machine, and how do they interact to produce knitted fabric?

- Knitting head: Contains needles that form loops of yarn to create stitches.

- Yarn feeder: Supplies yarn to the needles.

- Take-up roll: Pulls knitted fabric from the machine.

- Cambox: Controls the movement of needles and yarn to create specific knitting patterns.

- Sinkers: Help hold stitches in place as they are formed.

2. How do you troubleshoot a knitting machine that is producing fabric with dropped stitches?

Identify the cause of dropped stitches:

- Damaged needles or sinkers

- Incorrect tension settings

- Yarn breakage

- Cambox timing issues

Resolve the issue:

- Replace damaged parts

- Adjust tension settings

- Repair or replace yarn

- Recalibrate cambox

3. How do you calibrate a knitting machine to ensure precise stitch formation?

- Set needle heights using a gauge or ruler.

- Adjust sinker timing using a cambox.

- Check yarn tension and adjust as needed.

- Run test samples and inspect fabric quality.

- Fine-tune settings until optimal stitch formation is achieved.

4. What safety precautions should be taken when operating a knitting machine?

- Wear appropriate clothing, including safety glasses.

- Check for loose wires or moving parts before starting the machine.

- Keep hands and fingers clear of moving needles.

- Stop the machine immediately if any irregularities are observed.

- Follow manufacturer’s safety guidelines.

5. How do you perform preventive maintenance on a knitting machine to extend its lifespan and improve performance?

- Regular cleaning and lubrication of moving parts.

- Inspection and replacement of worn or damaged parts.

- Checking and adjusting tension settings.

- Calibrating the machine as needed.

- Tightening loose connections and bolts.

6. How do you determine the correct yarn type and tension settings for a specific knitting project?

- Consider the desired stitch size and fabric texture.

- Consult yarn manufacturer’s recommendations.

- Adjust tension settings based on yarn thickness and stitch pattern.

- Test different settings and observe fabric quality.

- Make adjustments until optimal results are achieved.

7. What are the different types of knitting machines, and what are their respective advantages and disadvantages?

- Advantages: Produce high-quality fabrics with intricate patterns.

- Disadvantages: Limited production speed, higher cost.

- Advantages: High production speed, suitable for seamless garments.

- Disadvantages: Limited pattern capabilities.

- Advantages: High production speed, mesh-like fabrics.

- Disadvantages: Limited pattern capabilities.

Flat knitting machines:

Circular knitting machines:

Warp knitting machines:

8. How do you troubleshoot a knitting machine that is producing fabric with uneven or irregular stitches?

Identify the cause:

- Damaged needles or sinkers

- Incorrect cambox timing

- Fluctuations in yarn tension

- Machine vibration

Resolve the issue:

- Replace damaged parts

- Recalibrate cambox

- Adjust tension settings

- Isolate and address sources of vibration

9. What are the latest advancements in knitting technology, and how have they impacted the industry?

- Electronic camboxes for precise stitch control

- Computer-aided design (CAD) software for pattern creation

- Automated yarn feeders for consistent tension

- High-speed knitting machines for increased productivity

- 3D knitting technology for complex shapes and structures

10. How do you stay updated with the latest techniques and developments in the knitting industry?

- Attend industry conferences and workshops

- Read trade publications and online forums

- Network with other professionals in the field

- Research new technologies and applications

- Participate in training programs offered by manufacturers or industry organizations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knitting Machine Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knitting Machine Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knitting Machine Fixers are skilled technicians responsible for maintaining, repairing, and troubleshooting knitting machines used in the textile industry. Their primary objective is to ensure optimal machine performance and minimize production downtime.

1. Machine Maintenance and Inspections

Regularly inspect, clean, and lubricate all machine components, including needles, sinkers, and camboxes.

Conduct routine diagnostics to identify potential issues and take preventive measures.

2. Fault Finding and Repair

Diagnose and resolve mechanical, electrical, and software issues that affect machine operation.

Replace or repair faulty components, such as needles, thread tensioners, and sensors.

3. Machine Adjustments and Calibration

Adjust and calibrate machine settings to optimize fabric quality and production efficiency.

Monitor production output and make necessary adjustments to ensure consistent yarn tension, stitch formation, and fabric appearance.

4. Troubleshooting and Problem Solving

Analyze and troubleshoot complex technical issues using diagnostic tools and engineering knowledge.

Develop and implement solutions to minimize production downtime and maximize machine efficiency.

Interview Tips

To ace the interview for a Knitting Machine Fixer position, candidates should focus on demonstrating their technical expertise, problem-solving abilities, and commitment to maintaining high-quality standards.

1. Prepare for Technical Questions

Review basic principles of knitting machine operation, including needle types, cam timing, and yarn tensioning.

Practice troubleshooting common issues, such as fabric defects, missed stitches, and tension problems.

2. Highlight Problem-Solving Skills

Provide specific examples of how you have successfully diagnosed and resolved complex technical problems in previous roles.

Explain your approach to problem-solving and emphasize your ability to think critically and develop effective solutions.

3. Emphasize Attention to Detail

Knitting Machine Fixers require meticulous attention to detail to ensure accurate machine settings and precise fabric quality.

Discuss your experience in adhering to quality standards and maintaining a clean and organized work environment.

4. Showcase Commitment to Learning

Express your enthusiasm for staying up-to-date with the latest knitting machine technology and industry best practices.

Mention any certifications or training programs you have completed or plan to pursue.

5. Prepare Industry-Specific Questions

Research the company and its products to demonstrate your interest in the organization and the industry.

Ask thoughtful questions about the specific knitting machines used, production goals, and quality control processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Knitting Machine Fixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.