Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Knitting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Knitting Machine Operator so you can tailor your answers to impress potential employers.

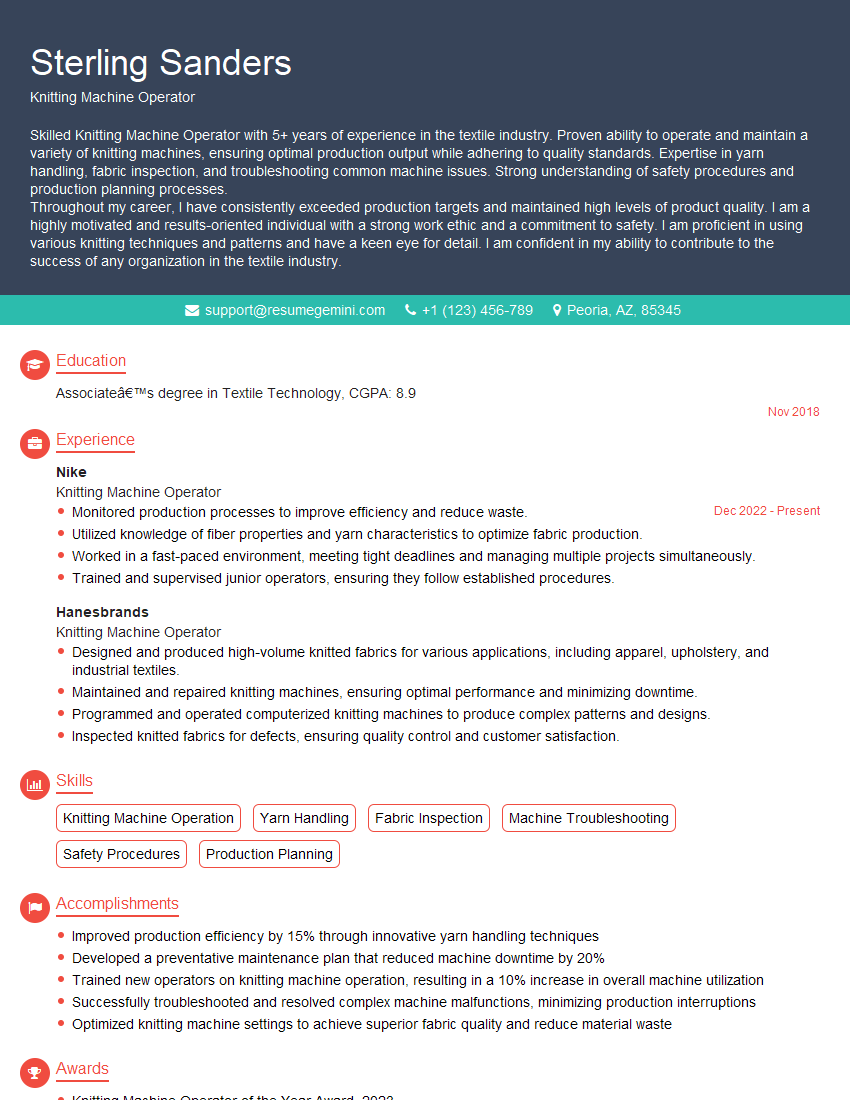

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knitting Machine Operator

1. Describe the different types of knitting machines and their uses in the industry?

- Flat Knitting Machine: This machine is used for producing flat fabrics in various patterns and textures. It is commonly employed in the production of garments, accessories, and home textiles.

- Circular Knitting Machine: This machine is used for producing circular fabrics in a continuous loop. It is widely used in the production of socks, hosiery, lingerie, and other tubular garments.

- Warp Knitting Machine: This machine uses a series of parallel yarns to create fabrics with intricate patterns and textures. Warp-knitted fabrics are often used in the production of lace, net, and mesh materials.

2. Explain the process of setting up and operating a knitting machine.

Yarn Preparation

- Selecting the appropriate yarn for the desired fabric.

- Winding the yarn onto cones or bobbins to ensure smooth feeding into the machine.

- Inspecting the yarn for any defects or knots.

Machine Setup

- Selecting the correct needles and sinkers for the desired stitch type and fabric weight.

- Adjusting the tension settings to ensure optimal yarn tension.

- Programming the machine with the desired pattern or design.

Machine Operation

- Feeding the yarn into the machine and starting the knitting process.

- Monitoring the machine’s performance, including yarn tension, stitch quality, and fabric formation.

- Making any necessary adjustments to maintain the desired fabric quality.

3. How do you troubleshoot common knitting machine problems, such as yarn breakage, tension issues, or missed stitches?

- Yarn Breakage: Identify the cause of the breakage (e.g., yarn tension, needle damage, or yarn quality) and take corrective action.

- Tension Issues: Adjust the tension settings on the machine to achieve the desired yarn tension. Inspect the yarn path for any obstructions or damage.

- Missed Stitches: Check if the needles or sinkers are damaged or bent. Ensure that the yarn is properly threaded and that the machine is correctly programmed.

4. What are the safety protocols that must be followed when operating a knitting machine?

- Wear appropriate safety gear, including protective eyewear, gloves, and earplugs.

- Keep the work area clean and free from tripping hazards.

- Never reach into the machine while it is operating.

- Follow lockout/tagout procedures when performing maintenance or repairs.

5. How do you ensure the quality of the knitted fabric produced on the knitting machine?

- Regularly inspect the knitted fabric for defects, such as holes, snags, or uneven stitches.

- Monitor the machine’s performance, including yarn tension, stitch quality, and fabric formation.

- Make any necessary adjustments to the machine or the yarn to maintain the desired fabric quality.

- Follow established quality control procedures and specifications.

6. What are the different factors that affect the quality of knitted fabric, and how do you control them?

- Yarn Quality: Use high-quality yarns that are free from defects and impurities.

- Machine Settings: Ensure that the machine is properly set up and calibrated to achieve the desired stitch type and fabric weight.

- Operator Skills: Train operators on proper machine operation and quality control techniques.

- Environmental Conditions: Control the temperature and humidity in the production area to prevent yarn breakage and fabric defects.

7. How do you maintain and repair a knitting machine to ensure optimal performance and longevity?

- Regular Cleaning: Clean the machine regularly to remove dust, lint, and yarn residue.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations.

- Inspections: Conduct regular inspections to identify any potential issues or worn parts.

- Repairs: Promptly repair any identified issues to prevent further damage to the machine.

- Spare Parts: Keep a supply of essential spare parts on hand to minimize downtime in case of repairs.

8. What are the latest advancements in knitting technology that you are aware of, and how do they impact the industry?

- Computerized Knitting Machines: These machines offer greater precision, speed, and design capabilities, enabling the production of complex and intricate fabrics.

- 3D Knitting: This technology allows for the creation of three-dimensional knitted structures, opening up new possibilities for product design and innovation.

- Smart Textiles: Knitting machines are now capable of integrating sensors and other electronic components into fabrics, creating garments with added functionality, such as temperature regulation or health monitoring.

9. How do you stay updated with the latest trends and developments in the knitting industry?

- Attend industry trade shows and conferences.

- Read industry publications and online resources.

- Network with other professionals in the field.

- Participate in training and development programs.

10. Why are you interested in working as a Knitting Machine Operator for our company, and what skills and experience do you bring that make you a suitable candidate for this role?

- I am passionate about the textile industry and have always been fascinated by the process of knitting.

- I have several years of experience operating knitting machines in a production environment.

- I am proficient in setting up, operating, and troubleshooting various types of knitting machines.

- I have a strong understanding of yarn properties, fabric structures, and quality control procedures.

- I am a highly motivated and results-oriented individual with a keen eye for detail.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knitting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knitting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knitting Machine Operators play a critical role in the textile industry by operating and maintaining knitting machines to produce various knitted fabrics.

1. Machine Operation

Skilled Knitting Machine Operators efficiently operate knitting machines to create different types of fabrics, ensuring smooth and precise production. They are responsible for:

- Setting up and adjusting machines according to production specifications.

- Loading and monitoring yarn supply, replenishing it as needed.

- Observing knitting processes, detecting any issues, and taking corrective actions promptly.

- Unloading finished fabrics and inspecting them for defects.

2. Machine Maintenance

To ensure optimal performance and prevent breakdowns, Knitting Machine Operators are responsible for regular maintenance of their machines. This includes:

- Cleaning and lubricating machines as per manufacturer’s instructions.

- Replacing worn or damaged parts, such as needles, sinkers, and cam plates.

- Performing minor repairs and adjustments to maintain machine functionality.

- Keeping a log of maintenance activities for future reference and troubleshooting.

3. Quality Control

Knitting Machine Operators are actively involved in maintaining the quality of produced fabrics. They:

- Inspect knitted fabrics for defects, such as yarn breaks, holes, or uneven stitches.

- Identify and correct any quality issues promptly to prevent defective fabrics from reaching customers.

- Adhere to established quality standards and follow company procedures.

4. Safety and Efficiency

Knitting Machine Operators prioritize safety and efficiency in their work environment. They:

- Follow established safety protocols to minimize risks and accidents.

- Use machines and equipment properly, optimizing production efficiency.

- Maintain a clean and organized work area to enhance productivity.

Interview Tips

To effectively prepare for a Knitting Machine Operator interview, consider the following tips:

1. Research the Company and Position

Thoroughly researching the company and the specific job requirements is crucial. This will demonstrate your enthusiasm and genuine interest in the role. Understand the company’s history, products, values, and growth trajectory.

2. Practice Your Skills and Knowledge

Review the job responsibilities and tailor your answers to highlight your relevant skills and experience. Be prepared to discuss your proficiency in operating and maintaining knitting machines. Practice common interview questions related to troubleshooting, quality control, and safety procedures.

- Example Outline:

- Describe a situation where you identified and resolved a knitting machine issue.

- Explain the quality control measures you follow to ensure the production of defect-free fabrics.

- Discuss the safety protocols you adhere to while operating knitting machines.

3. Prepare Examples of Your Work

If possible, bring tangible examples of your work, such as knitted fabric samples that showcase your expertise. This will provide the interviewer with a visual representation of your abilities and craftsmanship.

4. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive for your interview on time. Punctuality demonstrates respect for the interviewer and the company. Your appearance and demeanor should convey confidence and enthusiasm.

5. Ask Informed Questions

Asking thoughtful questions during the interview shows your engagement and interest in the position. Prepare questions that demonstrate your curiosity about the company, the industry, and the role itself. This will indicate your desire to learn and grow within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Knitting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.